An Efficiency Matching Production Line

A production line and efficiency technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problem of time-consuming waiting for workpieces, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

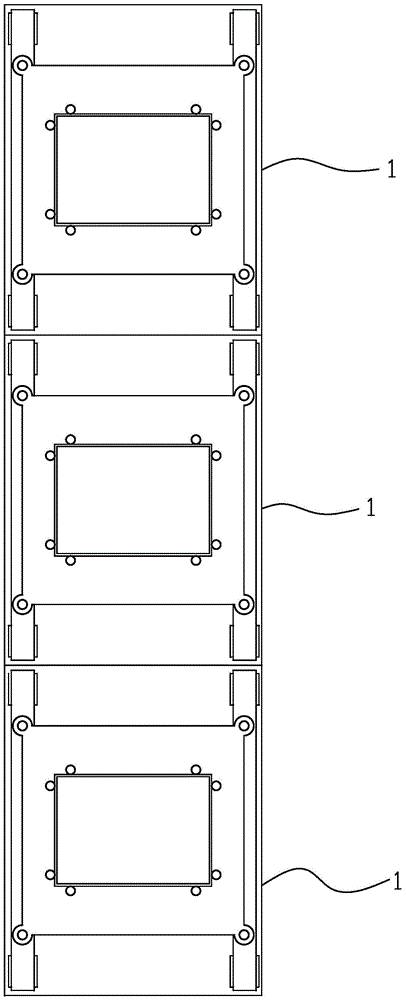

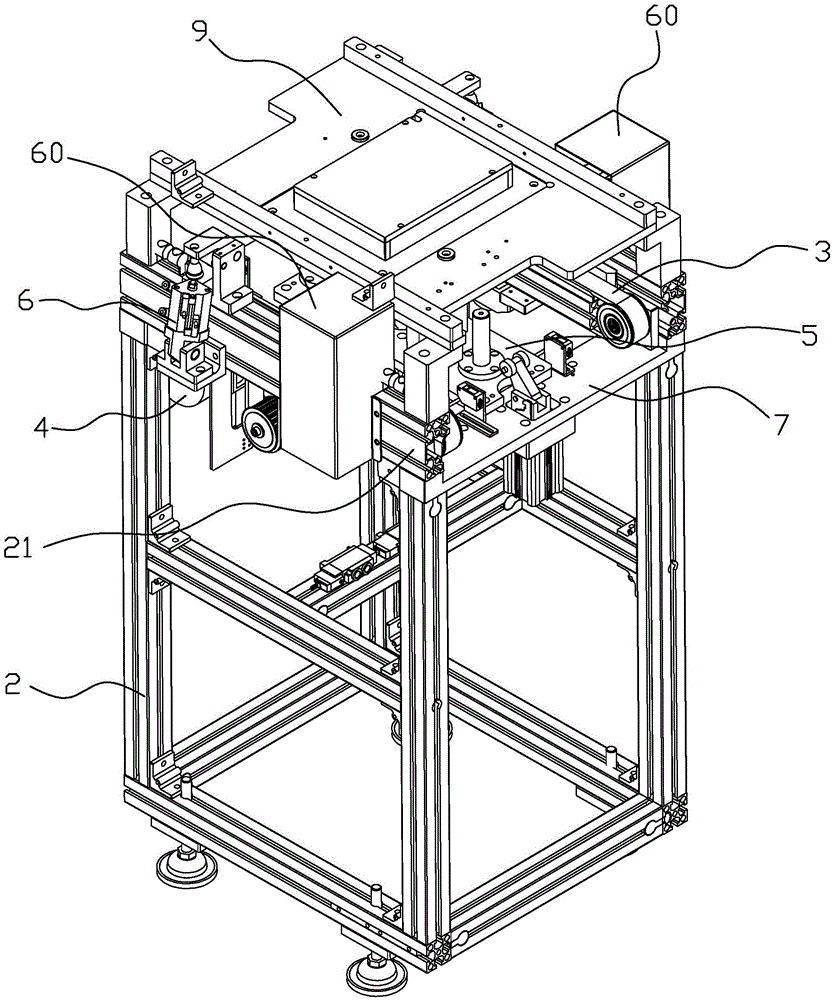

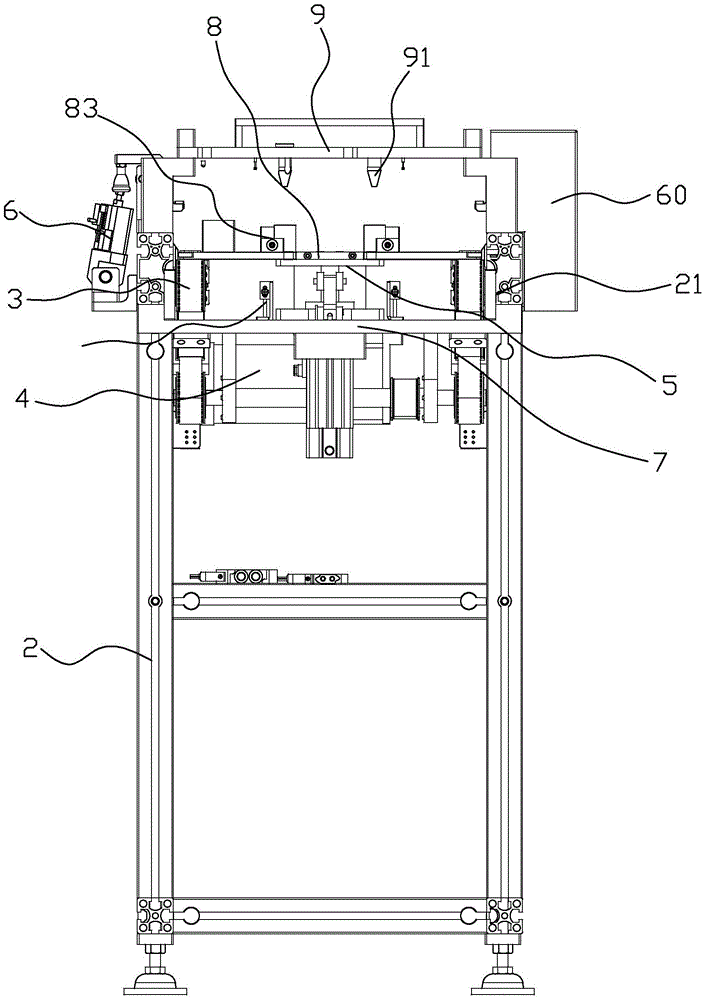

[0036] refer to Figure 1-4 , an efficiency matching production line, the production line is controlled by a computer control system, the production line includes at least one independent station module 1, and the production line can increase or delete the number of station modules 1 according to the difference in processing and testing products, and implement Simple, the station module 1 includes a frame 2, the frame 2 is a frame body, the frame 2 is provided with a transmission mechanism 3 and a power mechanism 4 for providing power to the transmission mechanism 3, the machine The frame 2 is also provided with a jacking mechanism 5 for jacking up the workpiece and a clamping mechanism 6 for clamping the workpiece, and a space for the workpiece to pass is provided between the clamping mechanism 6 and the transmission mechanism 3 .

[0037] refer to Figure 5 , Figure 6 , Figure 13 , Figure 15 , the jacking mechanism 5 includes a jacking plate 51 fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com