A clamping device for a reaction tank

A clamping device and reaction tank technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of increased production costs, broken reaction tanks, high damage rate of reaction tanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

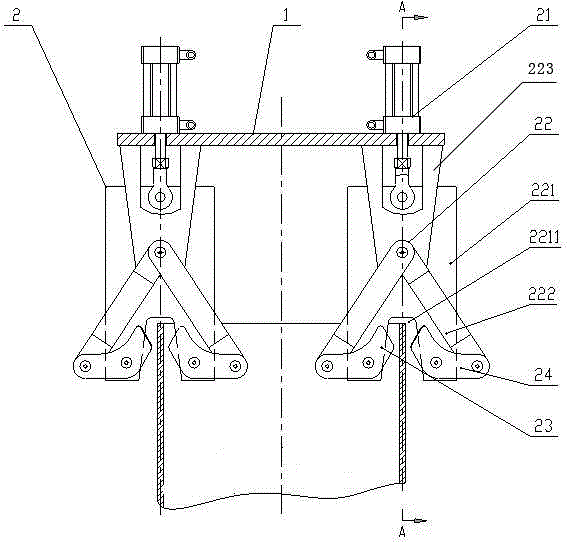

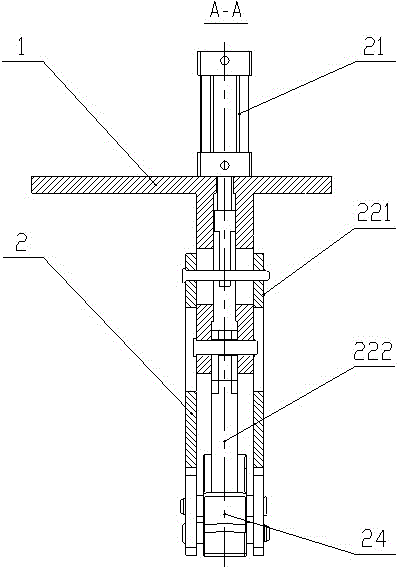

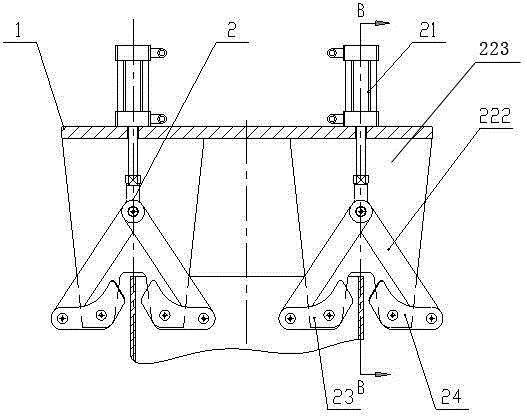

[0023] Such as figure 1 with figure 2 In the first specific embodiment shown, the connecting piece 22 includes a fixed plate 223, two connecting rods 222 and a push plate 221, the fixed plate 223 is fixedly connected with the hanger 1, and one end of the two connecting rods 222 is fixed to the The plate 223 is hinged, and the other end is respectively hinged with one end of the outer jaw 24 and the inner jaw 23; the other end of the outer jaw 24 and the inner jaw 23 is connected with the air cylinder or hydraulic cylinder 21 through the push plate 221, the specific embodiment Using a cylinder, the cylinder drives the outer jaw 24 and the inner jaw 23 to rotate around the pin shafts of the outer jaw 24, the inner jaw 23 and the two connecting rods 222 by driving the push plate 221, thereby realizing the outer jaw 24 and the inner jaw. The jaws 23 clamp or loosen the wall of the reaction tank.

[0024] The push plate 221 is made of a rectangular or trapezoidal steel plate, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com