A kind of environment-friendly coating that simulates green vegetation hyperspectrum and preparation method thereof

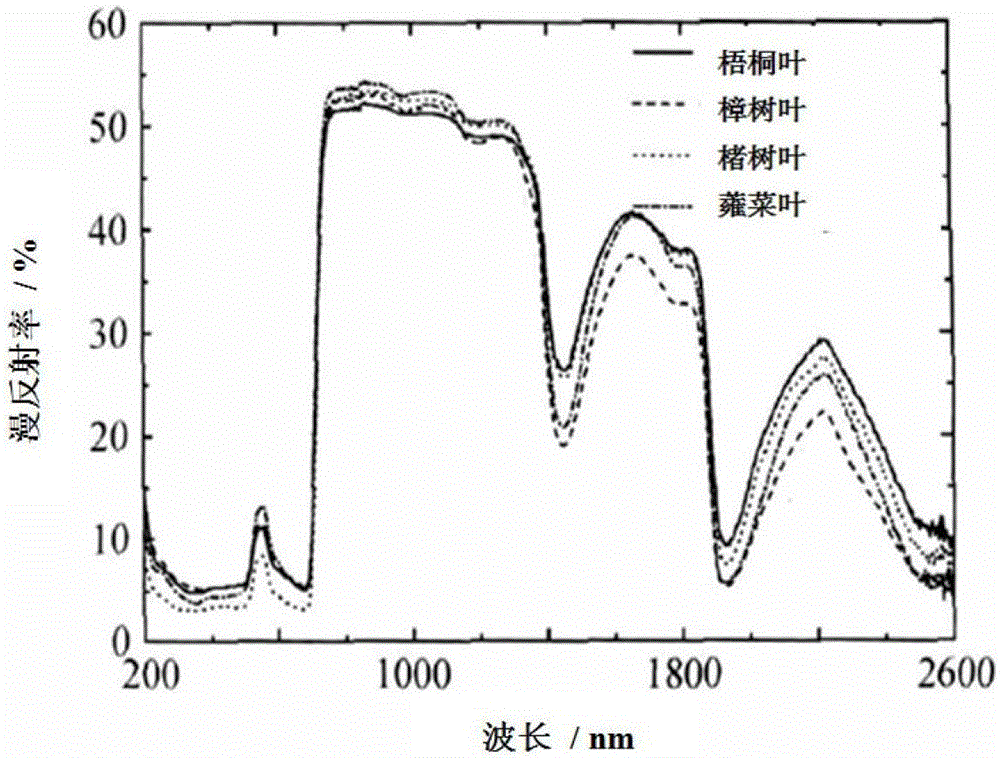

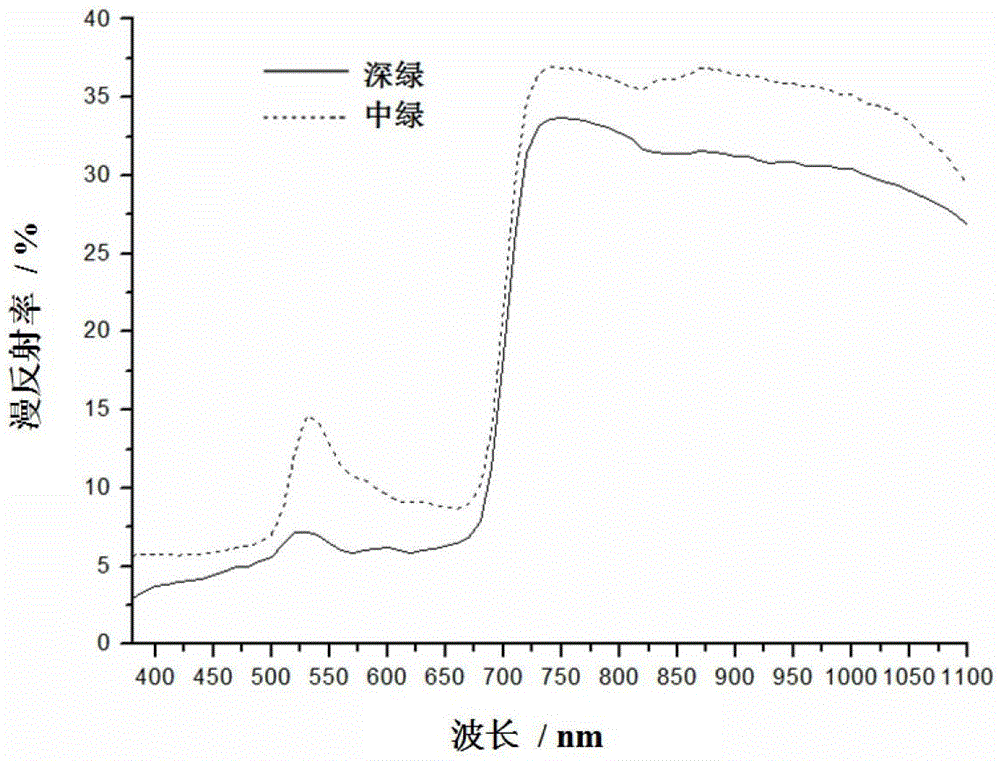

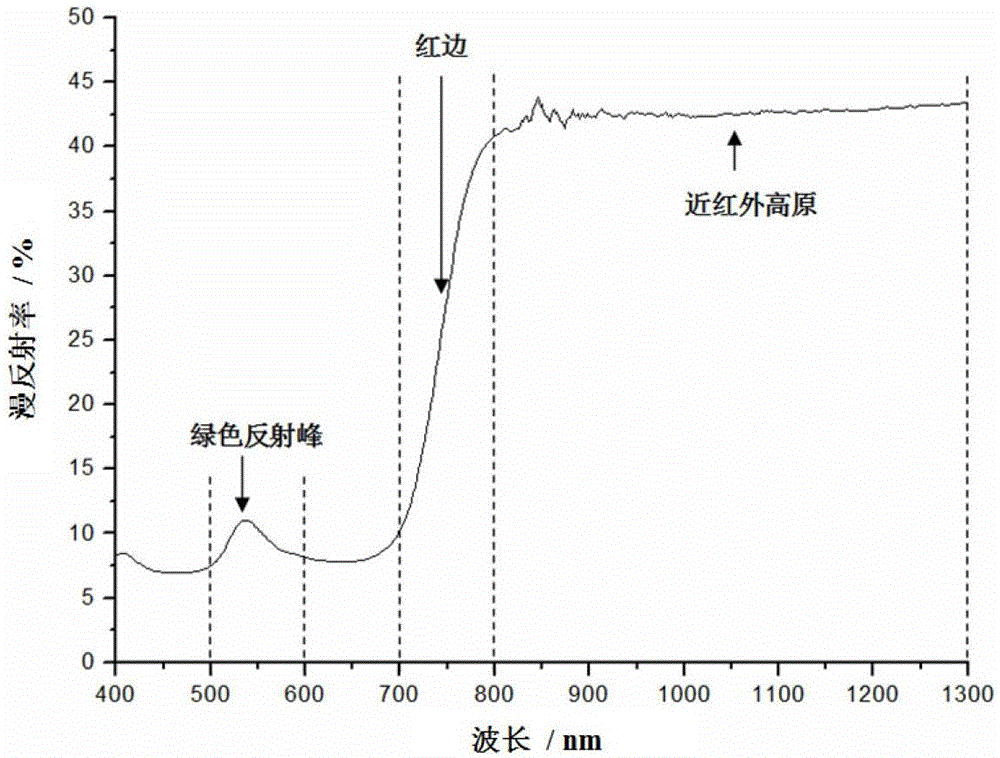

A green vegetation, hyperspectral technology, applied in the field of environmentally friendly coatings and their preparation, can solve the problems of low infrared light reflectivity, human harm, inability to meet the requirements of the allowable limit, etc., and achieve good hyperspectral bionic effect and moderate price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 prepares the environment-friendly coating that simulates green vegetation hyperspectrum

[0033] ① Preparation of component B

[0034] Component B of Example 1 is composed of 35% fluorocarbon resin, 20% special pigment, 16% filler, 4% dispersant, 0.5% leveling agent, 3% matting agent, 0.2% drier, and 21.3% mixed solvent , the specific raw materials and their dosage are shown in Table 1.

[0035] Table 1

[0036]

[0037] Note 1: The amount of rutile titanium dioxide, 1,4 diketopyrrolopyrrole organic red pigment, inorganic cobalt blue, benzimidazolone organic yellow pigment, green pigment, and black pigment refers to the total amount of the pigment in the total amount of special pigments percentage;

[0038] Note 2: The amount of talc powder, mica powder, and bentonite refers to the percentage of the filler in the total amount of filler.

[0039] Prepare component B according to the raw materials and their dosage in Table 1. Then, add mixed solvent, dis...

Embodiment 2

[0043] Embodiment 2 prepares the environment-friendly coating that simulates green vegetation hyperspectrum

[0044] ① Preparation of component B

[0045] Component B of Example 2 consists of 32% fluorocarbon resin, 25% special pigment, 15% filler, 2.5% dispersant, 0.5% leveling agent, 3% matting agent, 0.2% drier, and 21.8% mixed solvent , see Table 2 for specific raw materials and their amounts.

[0046] Table 2

[0047]

[0048]

[0049] Note 1: The amount of rutile titanium dioxide, 1,4 diketopyrrolopyrrole organic red pigment, inorganic cobalt blue, benzimidazolone organic yellow pigment, green pigment, and black pigment refers to the total amount of the pigment in the total amount of special pigments percentage;

[0050] Note 2: The amount of talcum powder and bentonite refers to the percentage of the filler in the total amount of filler.

[0051] Prepare the B component of Example 2 by the method of Example 1, and save it for subsequent use.

[0052] ② Prepar...

Embodiment 3

[0055] Embodiment 3 prepares the environment-friendly coating that simulates green vegetation hyperspectrum

[0056] ① Preparation of component B

[0057] Component B of Example 3 is composed of 35% fluorocarbon resin, 15% special pigment, 18% filler, 5% dispersant, 0.5% leveling agent, 2% matting agent, 0.2% drier, and 24.3% mixed solvent , see Table 3 for specific raw materials and their amounts.

[0058] table 3

[0059]

[0060] Note 1: The amount of rutile titanium dioxide, 1,4 diketopyrrolopyrrole organic red pigment, benzimidazolone organic yellow pigment, green pigment, and black pigment refers to the percentage of the pigment in the total amount of special pigments;

[0061] Note 2: The amount of talc powder and mica powder refers to the percentage of the filler in the total filler amount.

[0062] Prepare the B component of Example 3 by the method of Example 1, and save it for future use.

[0063] ② Preparation of environmentally friendly coatings that simulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com