A rhenium-containing high-strength hot-corrosion-resistant nickel-based single crystal superalloy

A technology of nickel-based single crystal and high-temperature alloys, which is applied in the field of nickel-based single-crystal superalloys, can solve the problem of few types of hot-corrosion-resistant single-crystal alloys, and achieve excellent hot-corrosion resistance and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0029] See Table 1 for the chemical composition of the nickel-based single crystal superalloy sample of the present invention. For convenience of comparison,

[0030] Table 1 also lists the chemical composition of the typical first-generation nickel-based single crystal superalloy PWA1483 and the typical second-generation single crystal superalloy Reńe N5.

[0031] Table 1 Alloy of the present invention (Example 1-8) and PWA1483, ReńeN5 chemical composition list (wt.%)

[0032] Alloy

[0033] Note: "Remainder" in the column of Ni content in the table means "balance".

Embodiment 4

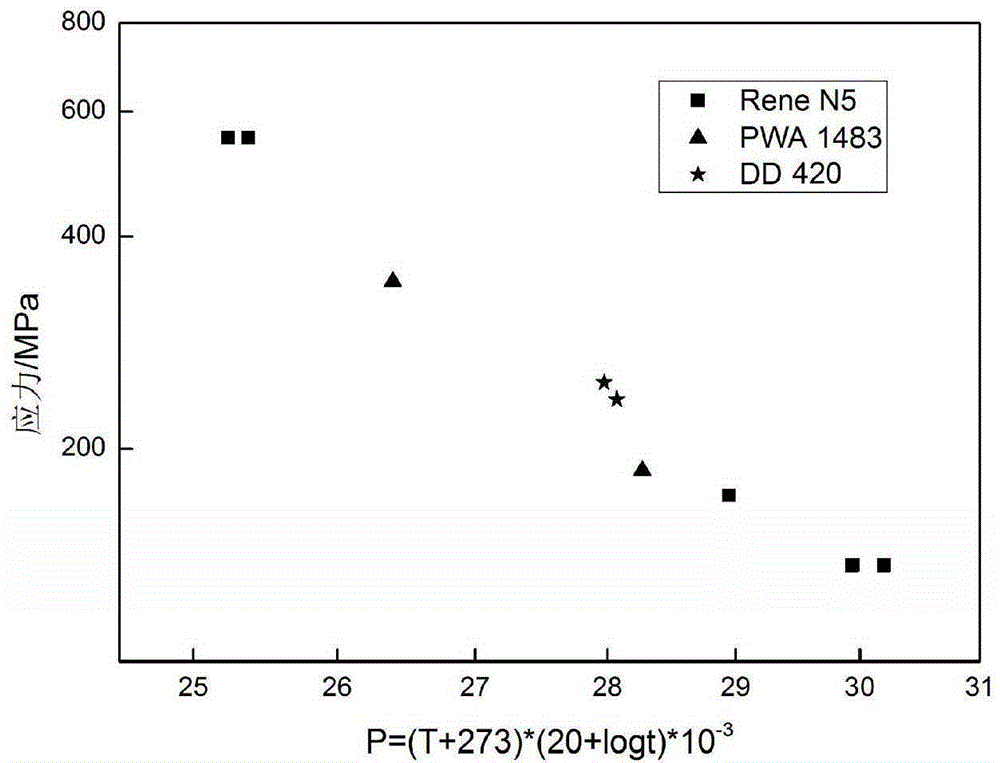

[0035] The Larson-Miller curve comparison of Example 1 alloy of the present invention and typical first-generation nickel-based single-crystal superalloy PWA1483 and typical second-generation single-crystal superalloy Reńe N5 is shown in figure 1 . The durability performance of the alloy of the present invention is equivalent to that of Reńe N5 and higher than that of PWA1483.

Embodiment 5

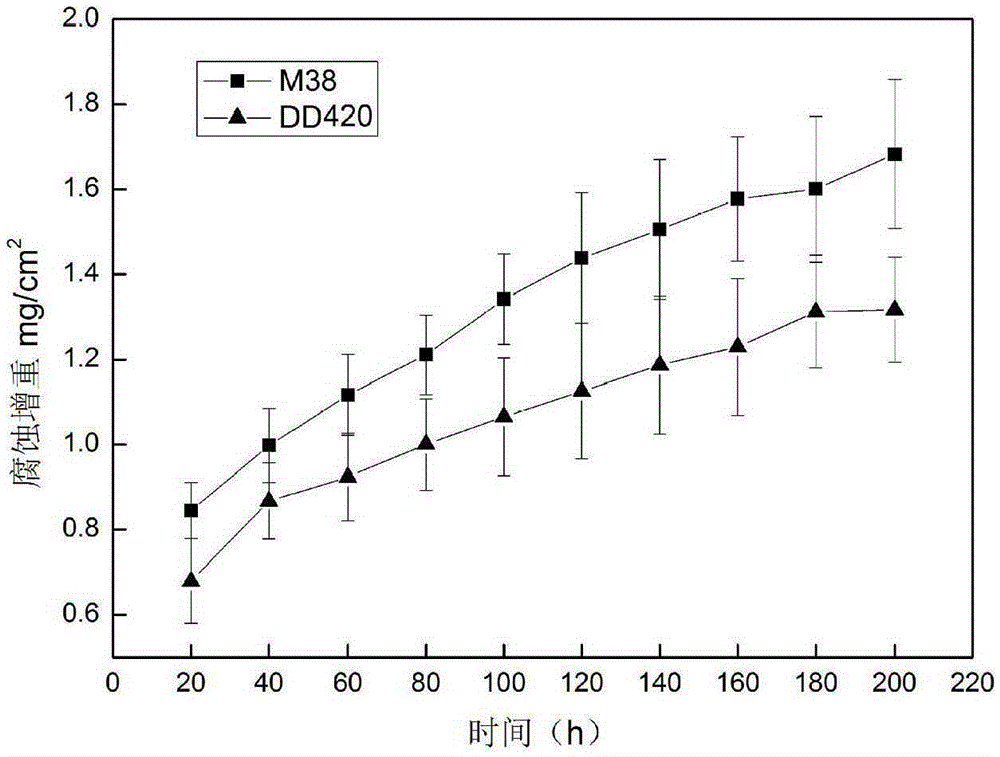

[0037] The comparison between the 900°C hot corrosion performance of the alloy of Example 2 of the present invention and the hot corrosion resistant alloy M38 is shown in figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com