Pipe-jacking construction method of underground passage and tunnel structure

A technology of tunnel structure and underground passage, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of difficult construction, slow construction progress, inconvenient demolition, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

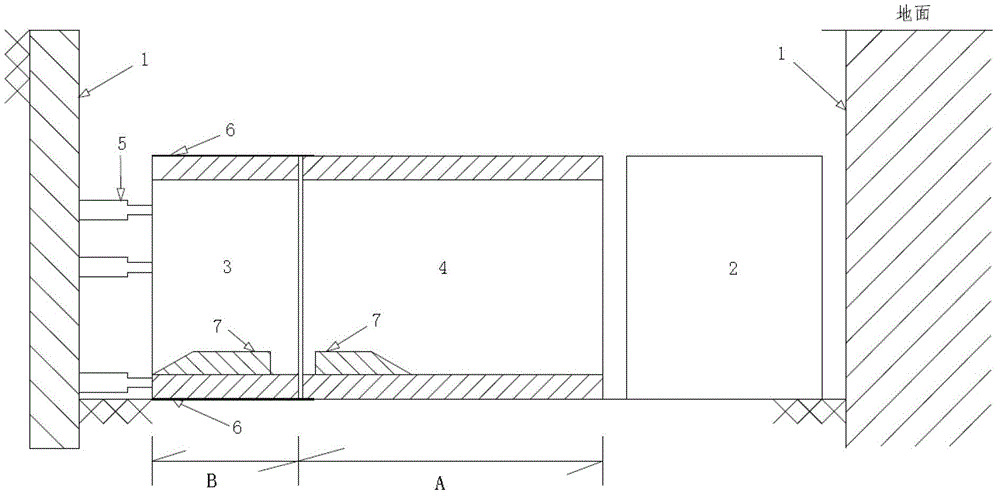

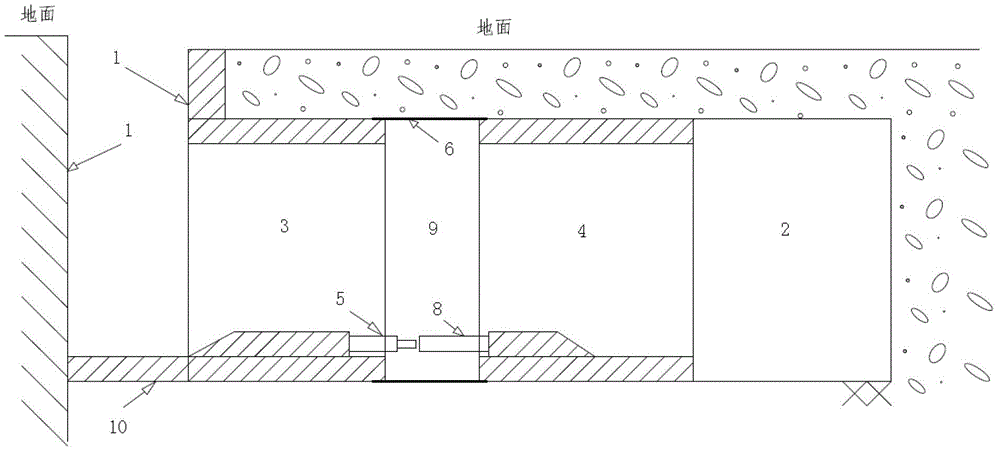

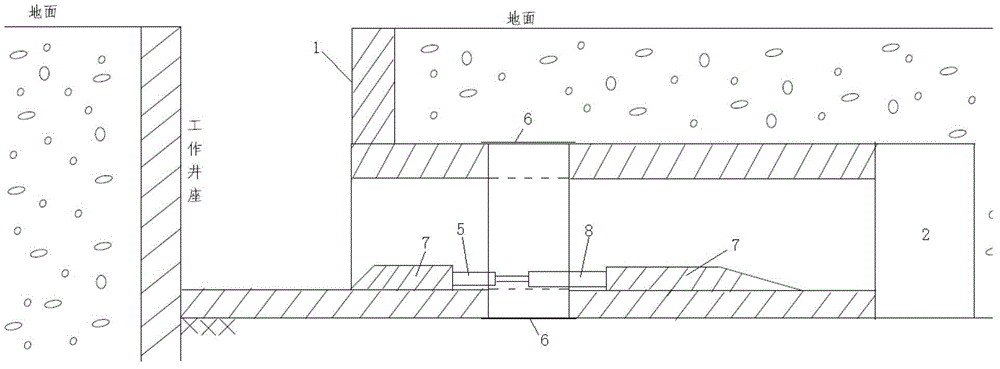

[0031] A construction method for pouring concrete in the relay room of underground channel tunnel pipe jacking construction, the construction method is divided into the following steps:

[0032] Step 1: see figure 1 , after the shield machine is installed in place, the concrete frame member is prefabricated at the back of the shield. The concrete frame member is divided into two sections, the first section is 4 to 6 meters long, and the second section is 2 to 3 meters long. The first section is called the balance section (or called the movable section). The function of the balance section is to transfer the reaction force generated by the shield excavation. The reaction force transmitted by the base plate is transferred to the base plate, and a concrete support pier is set on the base plate to transmit the force backward, and the support pier transmits the force backward through the force transmission column. The second section is called the anchor section (or fixed section)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com