Cable open-circuit point position detecting method

A detection method and breaking point technology, applied in the direction of the fault location, etc., can solve the problems of complex testing process and high testing requirements, and achieve the effect of wide application range, simple operation and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] First, by a multimeter, a resistance meter or other instruments, it is detected that a certain conductor of the cable 3 to be tested has an open circuit fault, then it is determined that the conductor with the open circuit fault is the conductor to be tested, and the other conductors in the cable to be tested are the first reference conductor 1, Then the present invention is used to locate the cable breaking point fault.

[0056] First technical solution of the present invention:

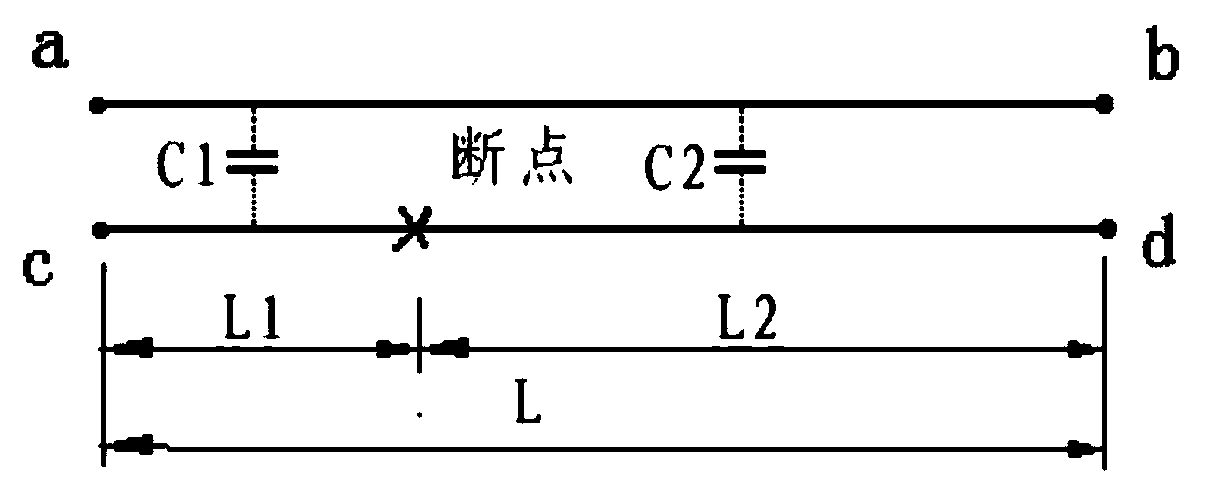

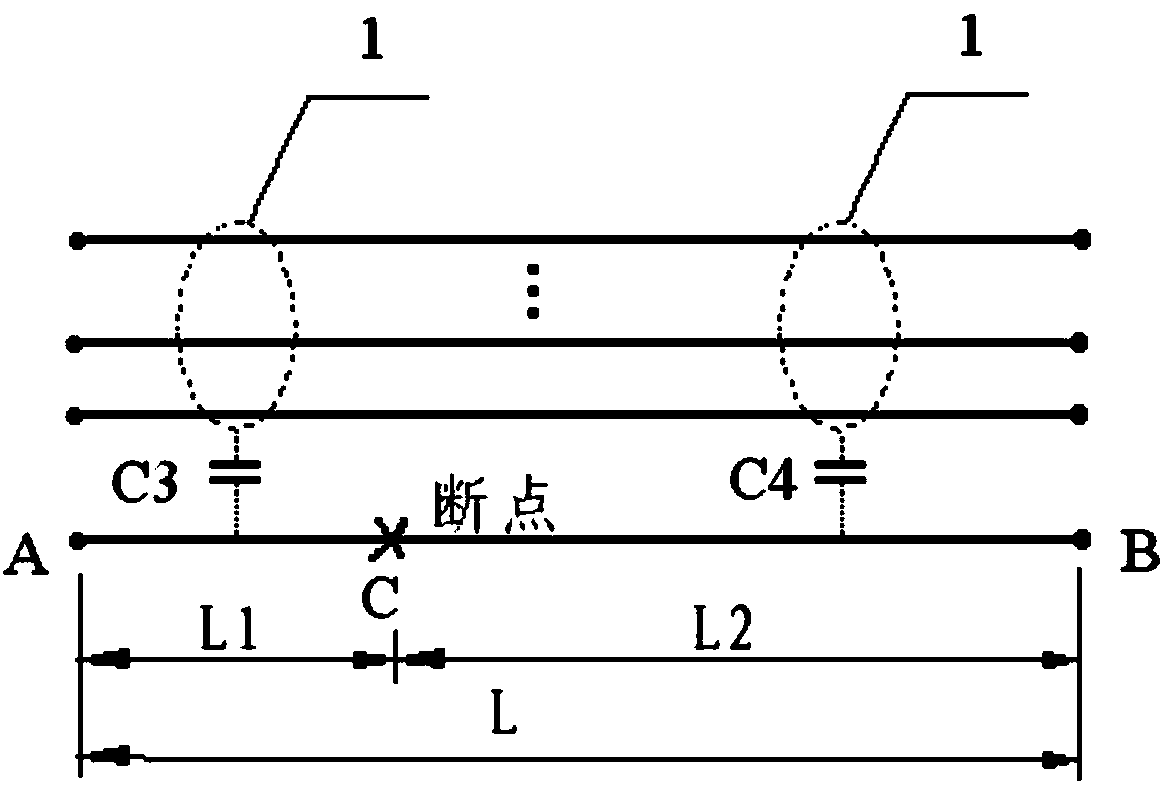

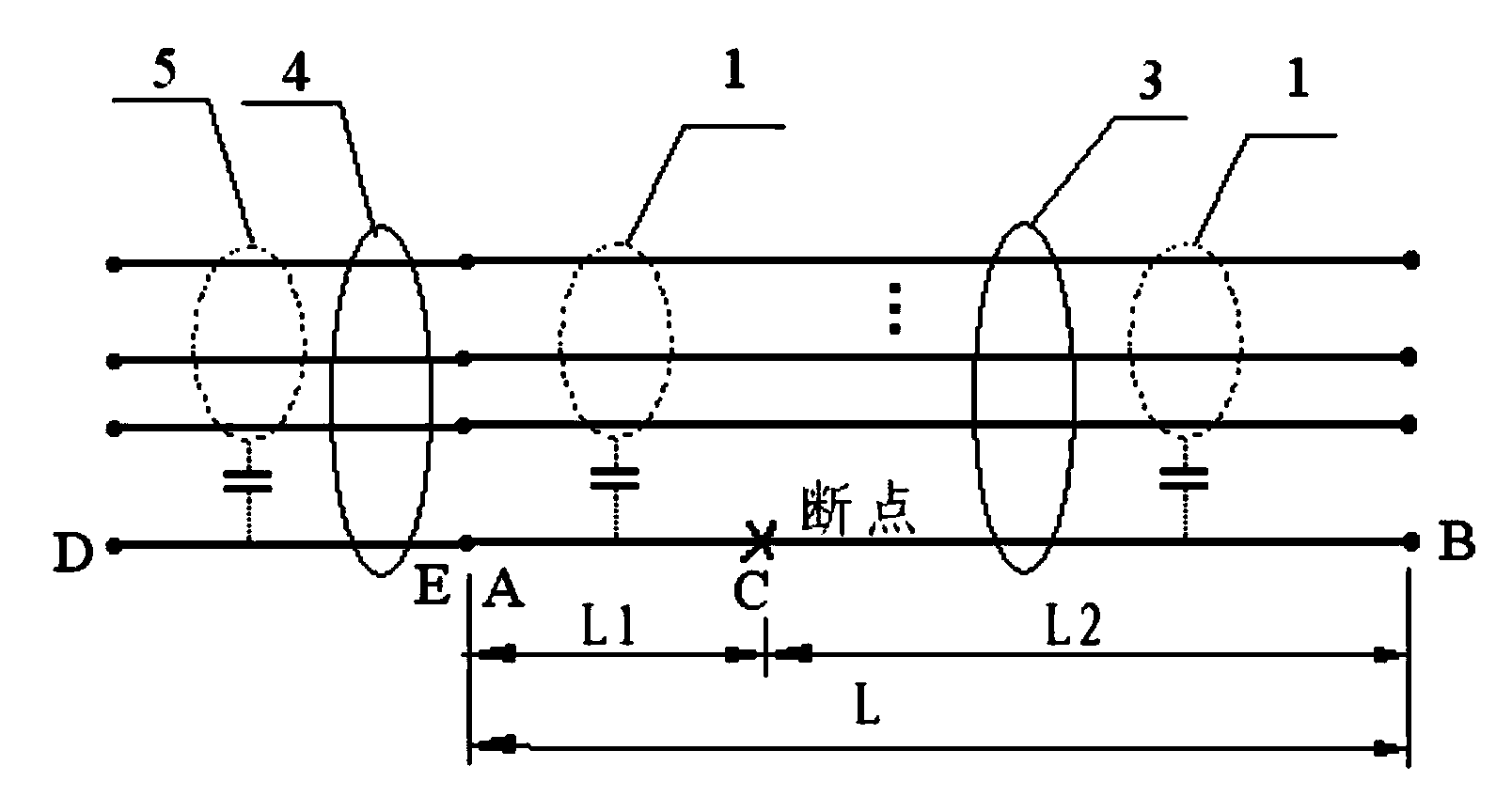

[0057] like figure 1As shown, the wire ab is the first reference wire, and the wire cd is the wire where the open circuit occurs. For a two-core cable, the distributed capacitance values between the wires on both sides of the break point of the wire cd and the wire ab are tested respectively. According to the difference between the two capacitance values The proportional relationship can measure the relative position of the break point in the cable to be tested, and realize the fault locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com