LCD (liquid crystal display) liquid crystal display module

A technology of liquid crystal display modules and polarizers, which can be used in nonlinear optics, instruments, optics, etc., and can solve problems such as chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

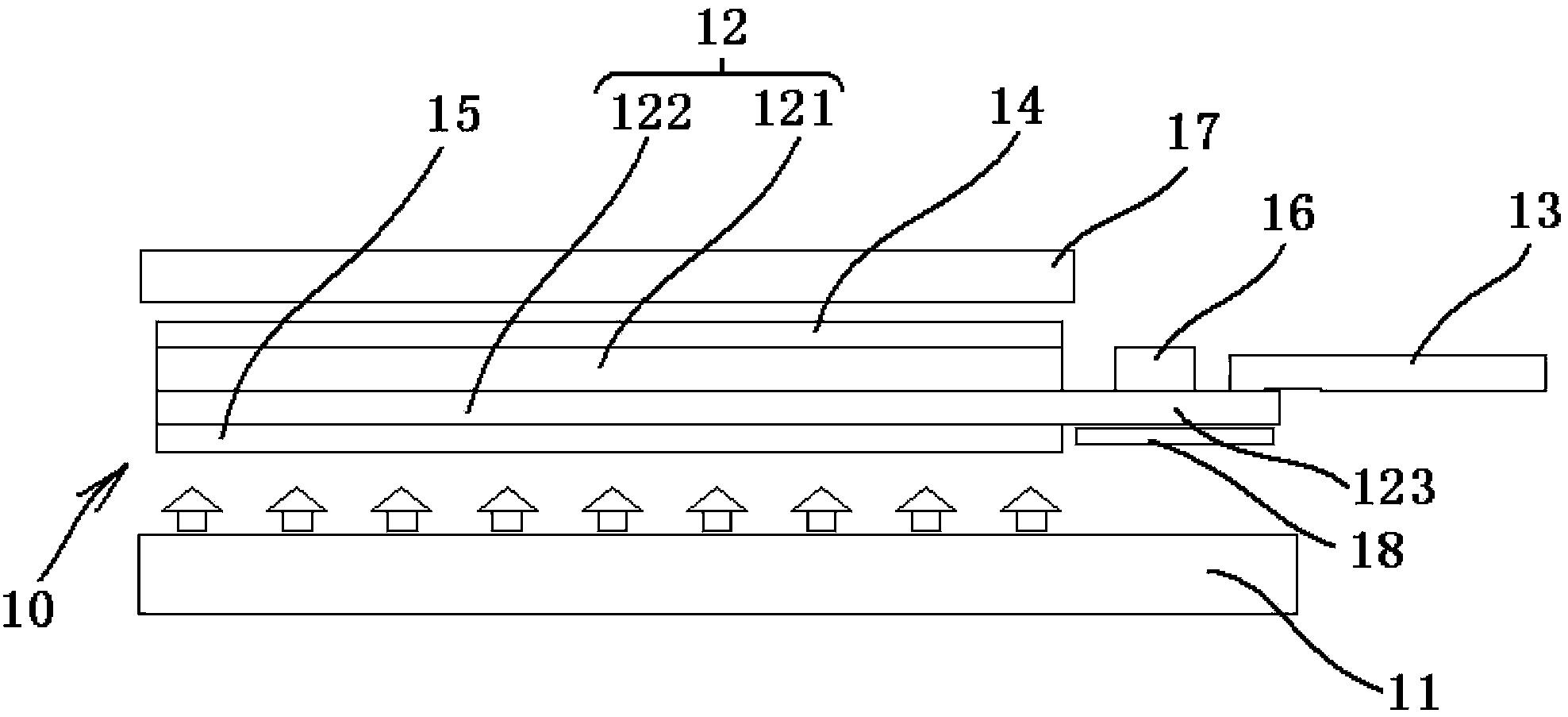

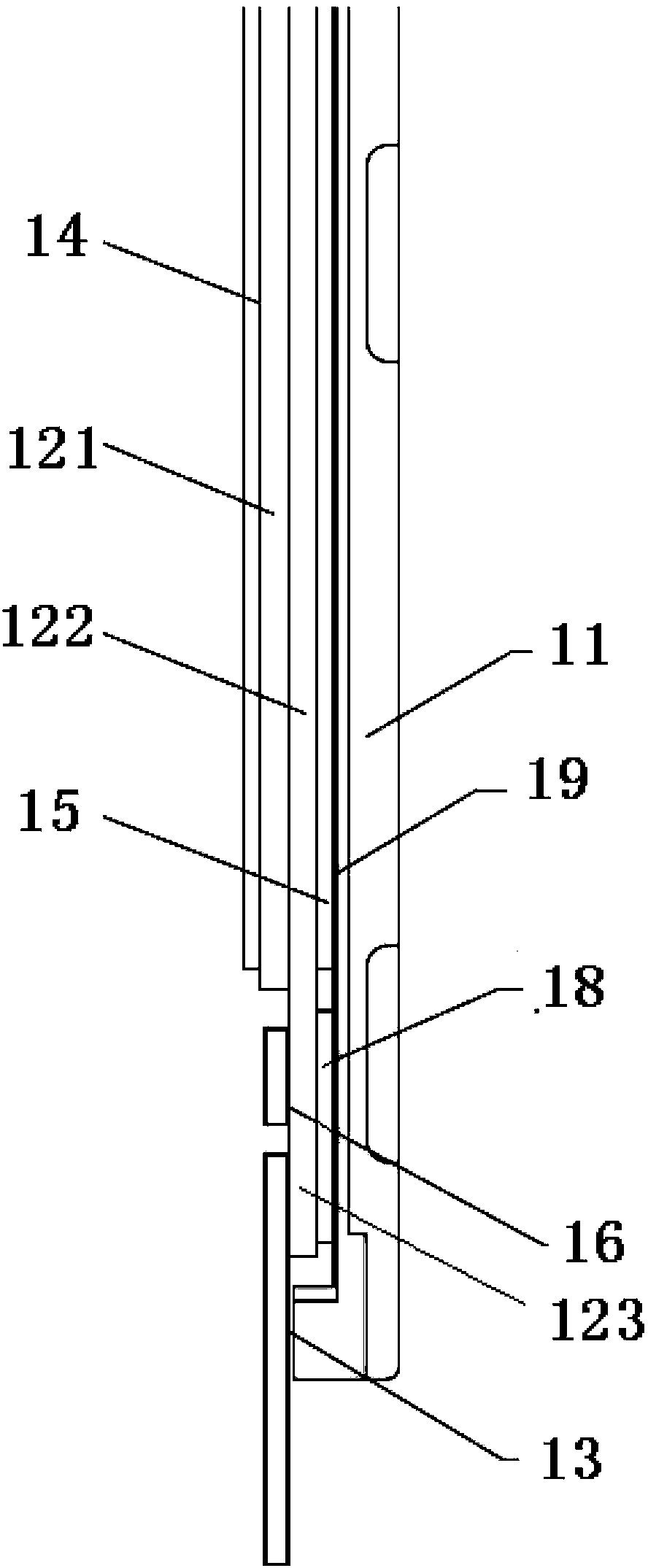

[0014] In the following, the LCD liquid crystal display module of the present invention will be further described in detail in conjunction with the drawings and specific embodiments of the present invention.

[0015] Please refer to the attached figure 1 : wherein it is shown that the LCD liquid crystal display module 10 includes a backlight 11, glass 12, flexible circuit board 13, upper polarizer 14, lower polarizer 15, driver chip 16 and touch screen 17, and the LCD liquid crystal display module performs the above-mentioned elements Encapsulation, the encapsulation structure is stacked with a touch screen 17, an upper polarizer 14, a glass 12, a lower polarizer 15, and a backlight 11 from top to bottom. 15, the flexible circuit board 13 and the driver chip 16 connected to the glass are arranged on the single-layer area 123. The lengths of the touch screen 17 and the upper polarizer 14 are roughly the same, and the glass 12 arranged under the upper polarizer 14 is used as an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com