Stepping motor rotor sheet clamping tool

A technology of rotor punching and stepping motors, which is applied in the manufacture of stator/rotor body, etc., can solve the problems such as the difficulty of precise installation of rotor punching, achieve the effects of improving work efficiency and processing accuracy, ingenious conception, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

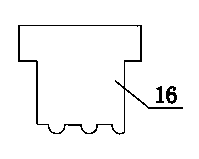

[0016] A stepper motor rotor punching and clamping tool, including a base, a quick clamping device and a jacket, the base is composed of a guide plate 1 and a splint 2, the splint 2 and the guide plate 1 are screwed together by bolts, and the center of the guide plate 1 is limited. Bit groove 3, clamping plate 2 is arranged on the two sides of limiting groove 3 and splint 2 protrudes inwardly limiting groove 3; Quick clip device includes handle 4, hinge chain 6, transmission shaft 8 and fixed seat 11, and fixed seat 11 is arranged on limiting In the bit groove 3, the hinged chain limiter 5 and the transmission shaft limiter 7 are arranged on the fixed seat 11, the hinge chain 6 is rotated with the hinged chain limiter 5, and the transmission shaft 8 is connected to the transmission shaft limiter 7 Inside, the handle 4 is driven and matched with the transmission shaft 8 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com