Novel cylinder body and ball pad mechanism

A cylinder and ball pad technology, applied in the field of pressure machinery, can solve the problems of easily broken piston rods, and achieve the effect of maintaining good parallelism and balancing the cylinder wall with less wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

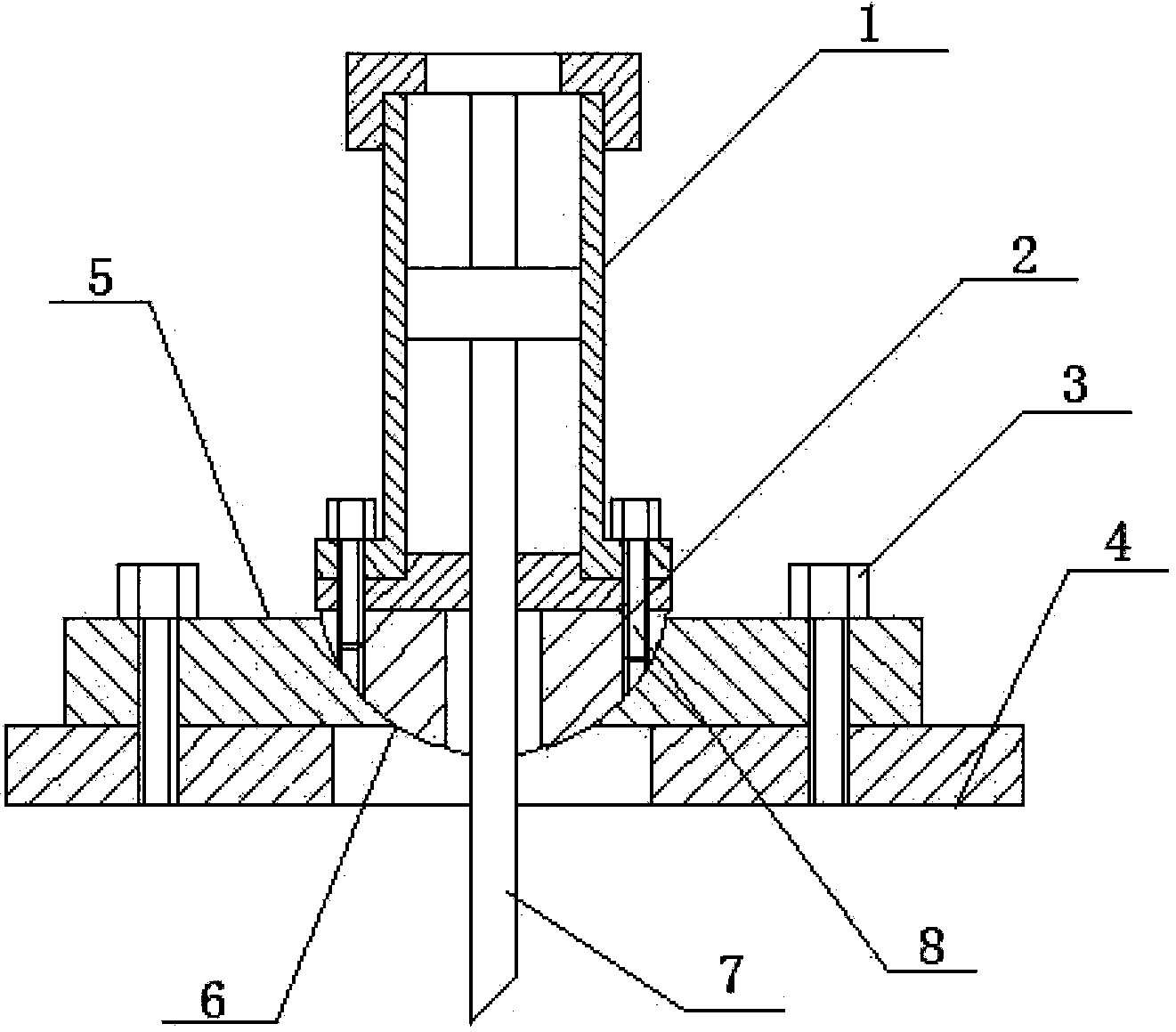

[0009] The cylinder ball pad mechanism has an adjusting plate (4), and a positioning plate (5) is installed on the top of the adjusting plate (4), and a spherical pit (6) is arranged in the middle of the positioning plate (5), and the spherical pit (6) ) is fixed by the bolt (3), and the silicone ball pad (2) and the cylinder body (7) are installed on the spherical pit (6), and the balance cylinder (1) is connected to the cylinder body (7), and the balance cylinder (1) It is installed in the spherical depression (6) in the middle of the positioning plate (5) through the silicone ball pad (2) and fixed by the positioning bolt (8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com