Portable bearing rotating precision comprehensive detection platform

A rotation accuracy and comprehensive detection technology, which is applied in angle/taper measurement, measuring devices, mechanical measuring devices, etc., can solve the problems of difficulty in popularization, high threshold, flooding of fake and inferior bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

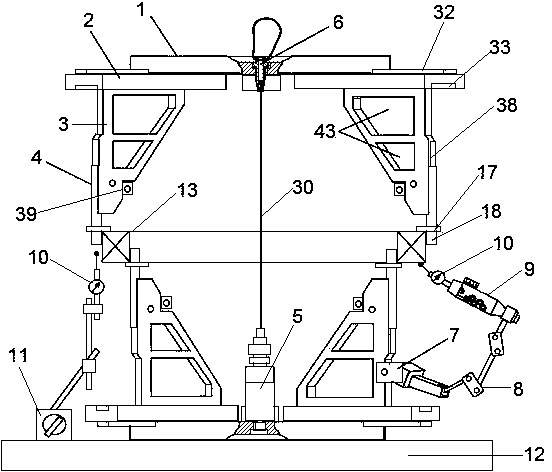

[0033] Such as figure 1 As shown, a portable bearing rotation accuracy comprehensive testing platform includes a bearing clamping diameter adjustable structural unit arranged symmetrically up and down, a dynamic anti-backlash unit 5, an anti-backlash assembly 6 and a portable measuring and clamping accessory 7.

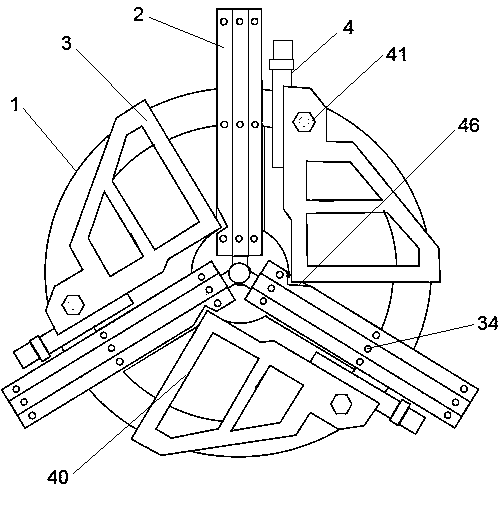

[0034] Each bearing clamping diameter adjustable structural unit includes a disc 1 , three bearing support plates 3 and three limit rod units 4 , and a radial adjustment rail 2 is arranged between the disc 1 and each bearing support plate 3 .

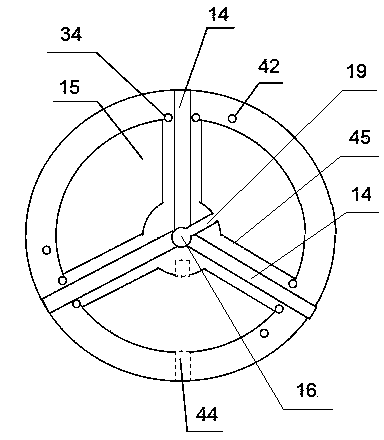

[0035] Such as image 3 As shown, the side of the disc 1 away from the bearing support plate 3 is preferably a standard plane; the side of the disc 1 adjacent to the bearing support plate 3 is uniformly provided with radial ribs 45 corresponding to the radial adjustment rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com