Testing system for fatigue crack propagation test under high/low temperature environment

A technology of fatigue crack growth and low-temperature environment, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc. It can solve the problems of low precision, lack of crack growth performance test system, and difficult fatigue crack growth performance test. Convenience and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

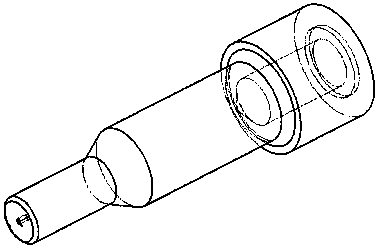

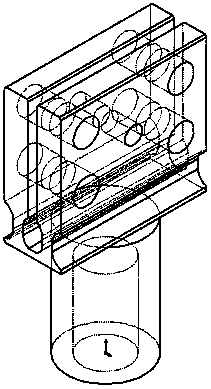

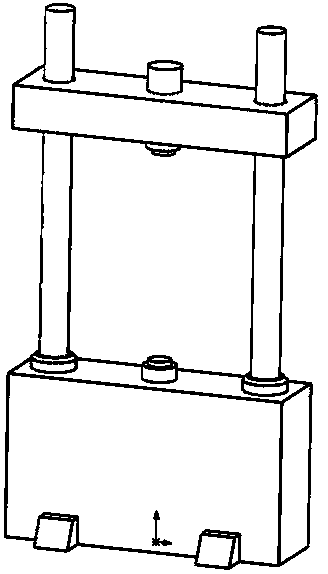

[0024] Specific implementation mode one: combine Figure 1 to Figure 6 Specific embodiments of the present invention will be described. The present invention is a fatigue crack growth test system under high / low temperature environment, which consists of a fatigue testing machine 1, a conversion joint 2, a sample fixture 5, a high / low temperature environment box 3, a liquid nitrogen tank 6, a positioning pin 7, and a crack observation System 8 and sample 4 are composed. exist Image 6 Among them, the sample holder 5 is connected with the sample 4, and the positioning pin 4 passes through the positioning holes of the sample holder 3 and the sample 4 for positioning, which can ensure that the sample 4 is loaded uniformly in the axial direction; The testing machine 5 is connected to the sample fixture 3; the liquid nitrogen tank 6 is connected to the high / low temperature environment box 3; the crack growth process of the sample is monitored and recorded by a three-axis follow-up...

specific Embodiment approach 2

[0026] Embodiment 2: The difference between this embodiment and Embodiment 1 lies in the design of the sample. The sample can be a plate with or without holes in the center, and the dimensional parameters can be different from those in Embodiment 1. , The other design concepts and connection methods of the fatigue crack growth test system under high / low temperature environment are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one lies in the design of the sample, the sample can be rod-shaped or other structural forms, and other design ideas and other design concepts of the fatigue crack growth test test system under high / low temperature environment The connection method is the same as that in the first embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap