Battery module performance detecting method for electric car

A battery module, electric vehicle technology, applied in the electrical field, can solve the problem of long time spent, and achieve the effect of improving the detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

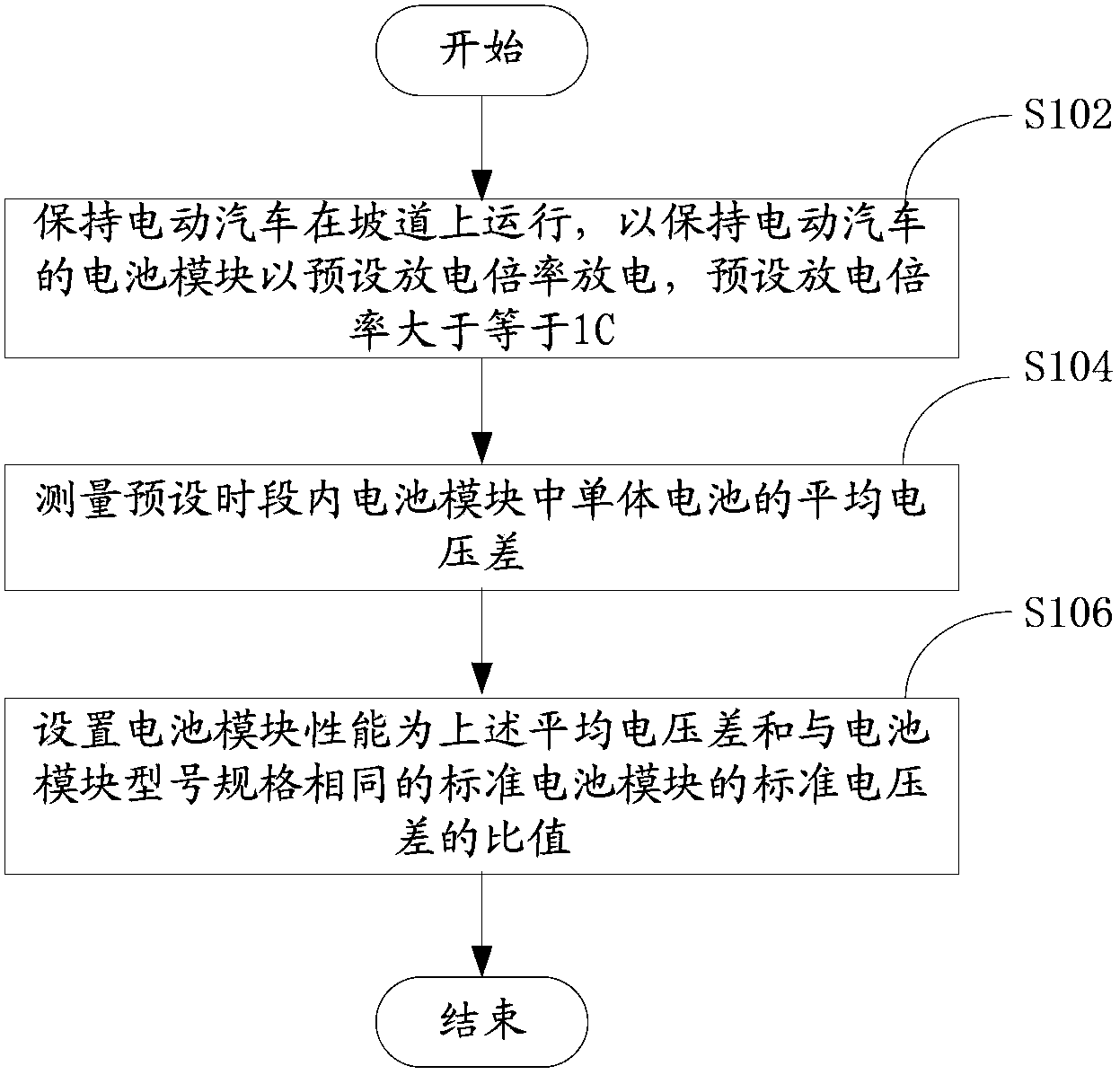

[0036] Such as figure 1 As shown, in one embodiment, a battery module performance detection method of an electric vehicle comprises the following steps:

[0037] Step S102 , keeping the electric vehicle running on a slope, so as to keep the battery module of the electric vehicle discharged at a preset discharge rate, and the preset discharge rate is greater than or equal to 1C.

[0038] Specifically, the preset discharge rate may be preset to a fixed value greater than or equal to 1C. Preferably, if the standard discharge rate of the battery module specified by the manufacturer of the battery module is greater than or equal to 1C, the preset discharge rate can be set to the standard discharge rate.

[0039] In one embodiment, the electric vehicle can be started on a certain slope, and the electric vehicle can be accelerated gradually, the discharge rate of the battery module can be monitored, and when the discharge rate reaches the preset discharge rate, the electric vehicle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com