Steel distribution risk early-warning method of automobile accessory enterprises

An auto parts and risk early warning technology, applied in forecasting, instrumentation, data processing applications, etc., can solve problems such as inability to synchronize updates, inability to automatically measure and pre-warn breakpoints, and lack of calculation models, so as to reduce business risks and avoid resource waste. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

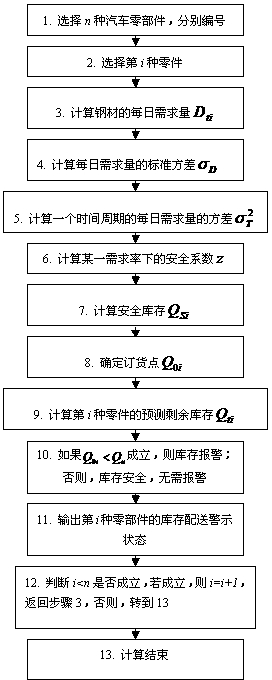

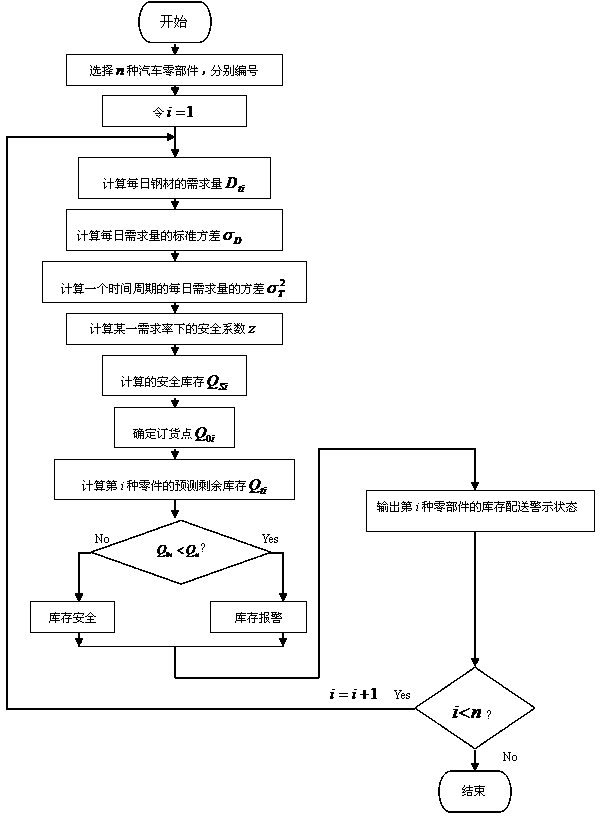

Method used

Image

Examples

Embodiment 1

[0030] (1) Select 6 kinds of auto parts, namely rear axle upper part, left beam lower part, right beam upper part, right beam lower part, control arm upper part left and control arm upper part right, numbered i =1, 2, 3, 4, 5, 6;

[0031] (2) order i =1, that is, select the upper plate of the rear axle for calculation;

[0032] (3) Use the year-on-year period ( T =7) The average value of the known demand replaces the predicted daily demand, assuming that the known demand of this cycle is 512.0471 kg, 660.3 kg, 669.06 kg, 540.7 kg, 590.5 kg, 530.2 kg, 667.5 kg , to calculate the daily demand for this cycle is 595.7582 kg;

[0033] (4) The standard deviation of the daily demand for this part is is 69.58228 kg;

[0034] (5) One time unit for this part T Variance of quantity demanded is 33891.86;

[0035] (6) Calculate the normal distribution probability of the enterprise under the 98% demand rate as 0.99, and find out its safety factor z =2.33;

[0036] (7) The calc...

Embodiment 2

[0044] (1) Select 5 kinds of auto parts, namely the lower part of the rear axle, the lower part of the left beam, the upper part of the right beam, the upper part of the control arm left and the upper part of the control arm right, i =1,2,3,4,5;

[0045] (2) order i =1, that is, select the lower part of the rear axle for calculation;

[0046] (3) Use the year-on-year period ( T =7) The average value of the known demand replaces the predicted daily demand, assuming that the known demand of this cycle is 445.7412 kg, 582.8923 kg, 466.3 kg, 563.4 kg, 455.9 kg, 512.3 kg, 557.3 kg , to calculate the daily demand for this cycle is 511.9762 kg;

[0047] (4) The standard deviation of the daily demand for this part is is 56.78289 kilograms;

[0048] (5) One time unit for this part Variance of quantity demanded is 22570.08;

[0049] (6) Calculate the normal distribution probability of the enterprise under the 98% demand rate as 0.99, and find out its safety factor z =2.33; ...

Embodiment 3

[0058] (1) Select 4 kinds of auto parts, which are the lower part of the front beam, the lower part of the left beam, the lower part of the right beam and the upper part of the control arm. i =1,2,3,4;

[0059] (2) order i =1, that is, select the lower part of the front beam for calculation;

[0060] (3) Use the year-on-year period ( T =7) The average value of the known demand replaces the predicted daily demand, assuming that the known demand of this cycle is 2500 kg, 1800 kg, 3000 kg, 5000 kg, 4000 kg, 3500 kg, 2900 kg , to calculate the daily demand for this cycle is 3242.86 kg;

[0061] (4) The standard deviation of the daily demand for this part is is 1043.8026 kg;

[0062] (5) One time unit for this part Variance of quantity demanded is 7.63E+06;

[0063] (6) Calculate the normal distribution probability of the enterprise under the 98% demand rate as 0.99, and find out its safety factor z =2.33;

[0064] (7) The calculated safety stock is 6434.63 kg;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com