Dual-gas route type heat-sensitive fire detector and detection method thereof

A fire detector and route-type technology, applied in the environmental field, can solve the problems of detecting pipeline leakage faults, false alarms of detectors, and limitation of application range, so as to save labor installation costs, ensure work reliability, and save equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific drawings and embodiments.

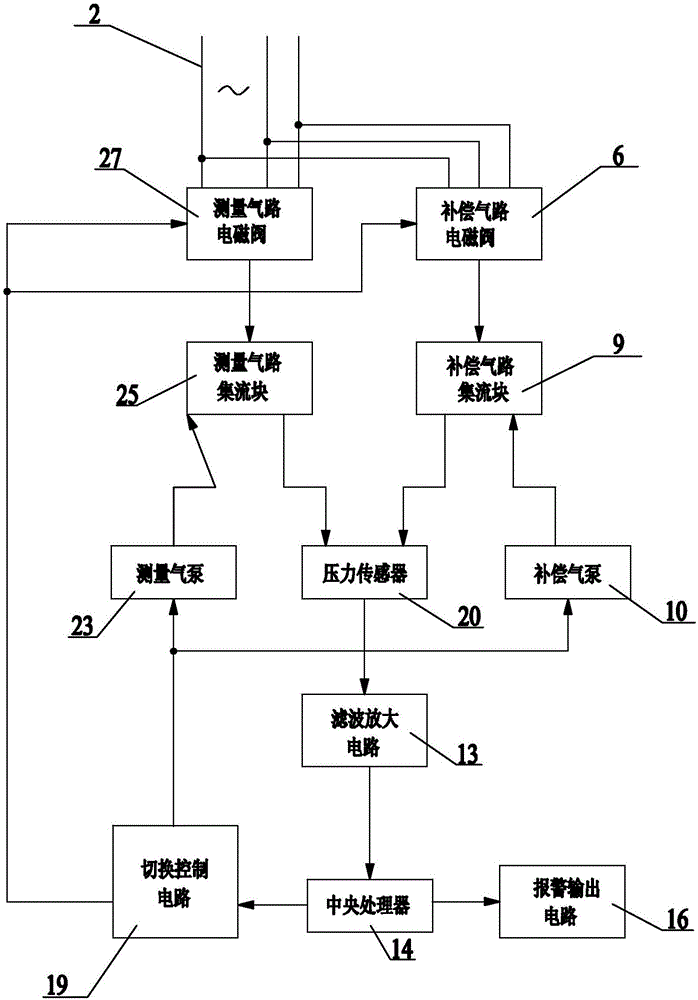

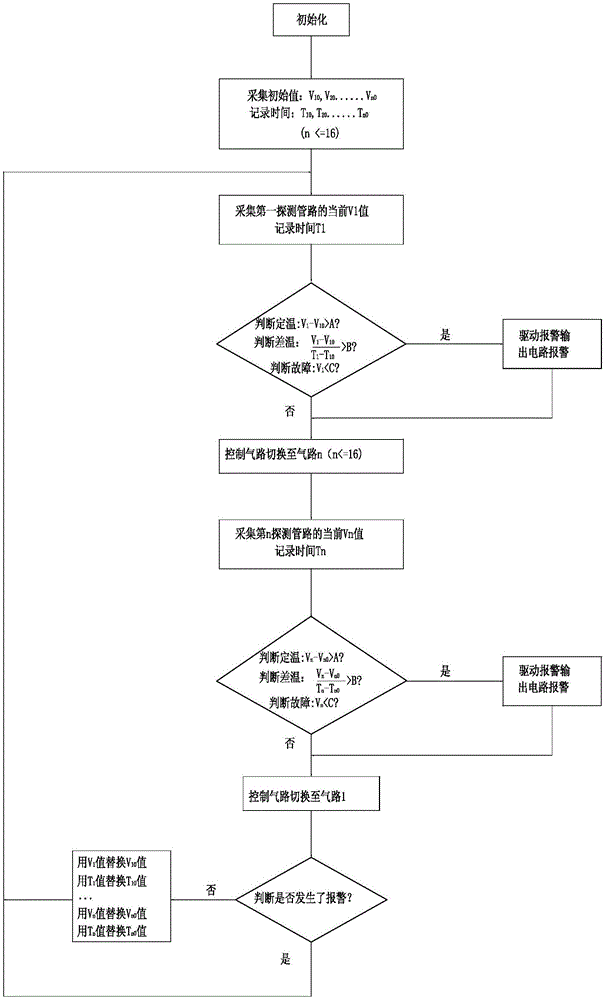

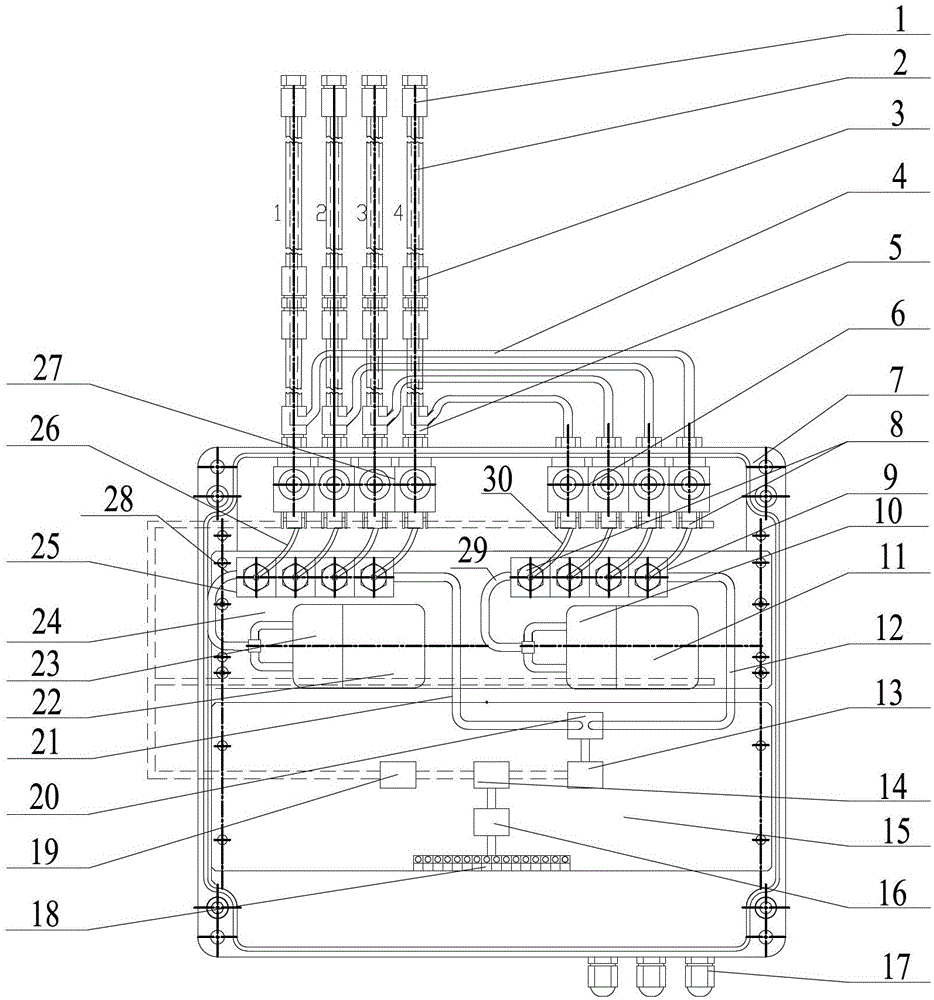

[0029] Such as figure 1 with figure 2 As shown: in order to accurately detect temperature such as fire, the present invention includes a box body 7 and several detection pipelines 2 located outside the box body 7, and the detection pipeline 2 includes a detection outer tube and a detection tube located outside the detection The detection inner tube in the tube, the detection outer tube is filled with the first detection gas, and the detection inner tube is filled with the second detection gas, the expansion coefficient of the first detection gas and the second detection gas are different; the detection pipeline 2 has a second One end and the second end corresponding to the first end; the box body 7 is provided with a pressure sensor for measuring the air pressure value of the outer pipe in the detection pipeline 2 and the air pressure value of the inner pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com