Flexible and fine grinding system of food waste processor

A food waste treatment and crushing technology, which is applied in the direction of grain processing, etc., can solve the problems of wasting water resources, not finely crushed, and the blockage of the drain, and achieves the effect of reasonable structure, convenient use, and avoiding blockage of the drain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described in further detail now in conjunction with accompanying drawing.

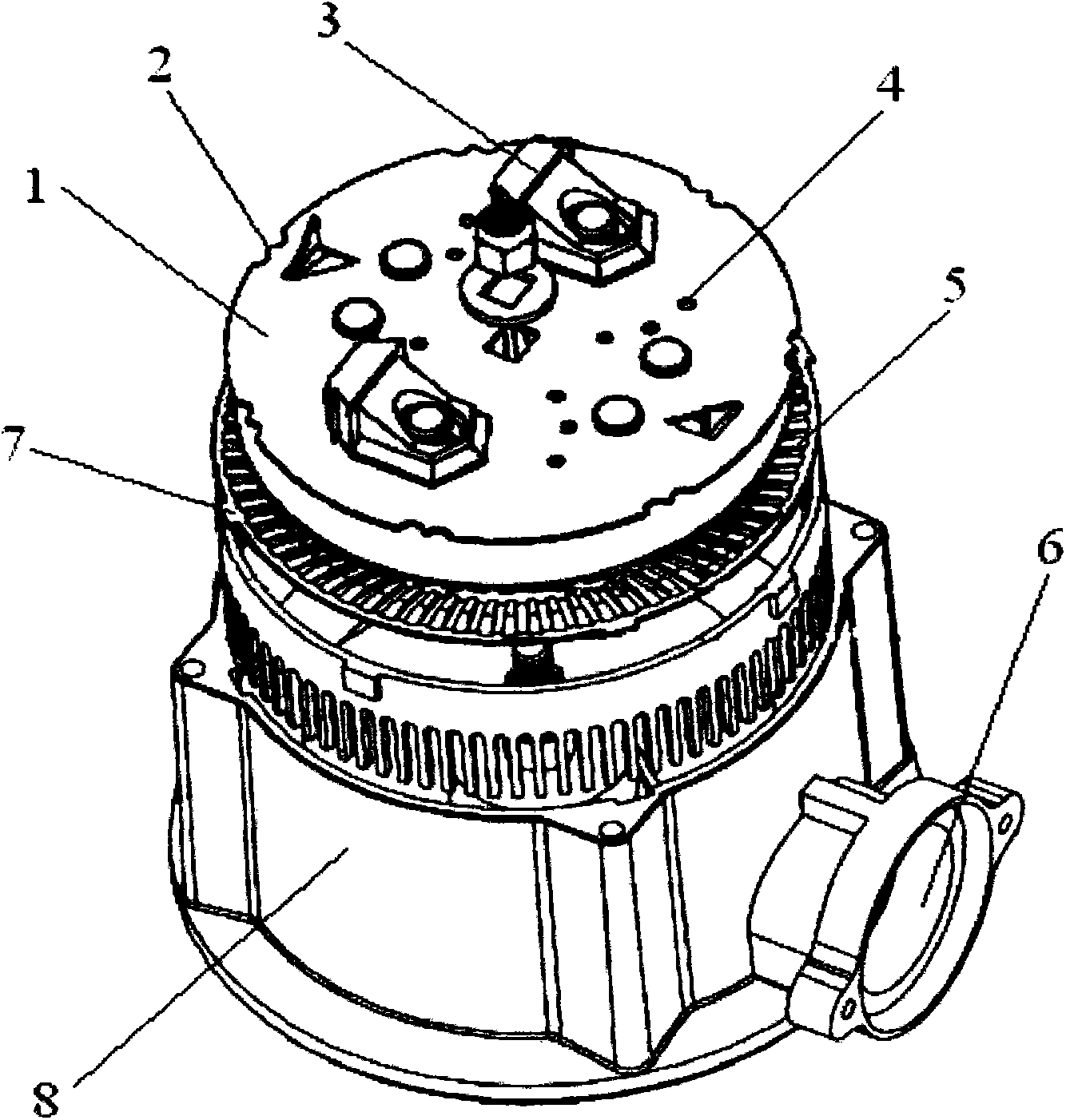

[0014] A food waste processor koji grinding fine grinding system, including a grinding disc 1, a sewage outlet 6, and a cavity 8, the sewage outlet 6 is located on one side of the cavity 8, and the top of the cavity 8 is provided with a pusher 7 , the outer circumference of the pusher 7 is provided with a plurality of curved grinding teeth 5 evenly distributed, the pusher 7 is provided with a grinding disc 1, and the top of the grinding disc 1 is symmetrically provided with two grinding hammers 3, so The top of the grinding disc 1 is also provided with a plurality of dropping holes 4, and the top of the grinding disc 1 has multiple sets of grinding teeth 2 evenly distributed on the outer edge.

[0015] Specifically, one side of the grinding hammer 3 is provided with a plurality of corners, and the other side is a slope.

[0016] Specifically, the outer edge of the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com