Shock absorber piston rod rolling groove tooling

A piston rod and shock absorber technology, which is applied in the field of automotive shock absorber piston rod rolling groove tooling, can solve problems such as low production efficiency, reduce workpiece strength, and stress concentration, reduce frequent tool changes, and improve processing efficiency , The effect of improving the processing quality of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

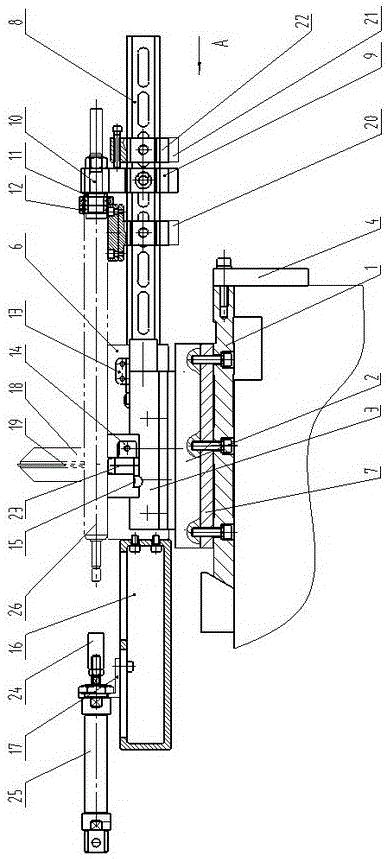

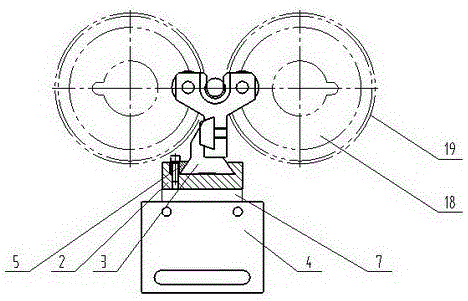

[0008] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment: As shown in the figure, an adjustment backing plate 7 is installed on the bottom plate 1, a dovetail groove plate 2 is installed on the adjustment backing plate 7, and a longitudinal adjustment dovetail 3 is installed on the dovetail groove plate 2 , the longitudinal adjustment dovetail 3 and the dovetail groove plate 2 are compressed with wedge-shaped bead 5, the vertical adjustment dovetail 3 is installed with a tooling vertical plate 6, and the tooling vertical plate 6 is equipped with a turning tool 23, a knife adjustment screw 15, a holed dovetail strip 8, and a bracket 16. The turning tool 23 and the tooling vertical plate 6 are clamped with the pressing block 14, the perforated dovetail bar 8 and the tooling vertical plate 6 are clamped with the pressing block 13, and the perforated dovetail bar 8 is equipped with a supporting plate 20 and an adjusta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com