Tooth-shaped insert for packaging lead frame

A technology for encapsulating leads and frames, which is applied in the field of tooth inserts, and can solve problems such as poor fitting of lead frame tube legs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

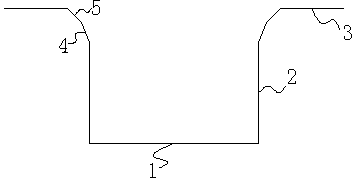

[0026] Such as figure 1 As shown, the present invention includes an open slot for inserting the tube legs of the lead frame, the open slot includes a slot bottom 1 , a slot wall 2 and a slot 3 , and a chamfer 4 transitions between the slot wall and the slot.

[0027] The legs of the lead frame extend into the open groove, the space surrounded by the bottom of the groove and the wall of the groove is suitable for the shape of the lead frame, and the inner diameter of the open groove is slightly larger than the leg of the lead frame for potting and encapsulation, a preferred example of the present invention The edge of the groove wall of the open groove is 0.05mm longer than the leg of the lead frame. In order to prevent the poured glue from overflowing the open groove, a chamfer transition can be provided between the groove wall of the open groove and the notch of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com