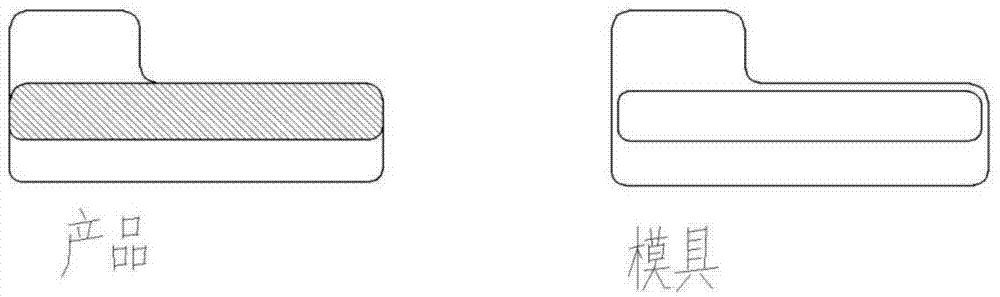

Double sided adhesive tape processing method without adhesive overflow

A processing method and technology of double-sided tape, applied in the direction of bonding method, adhesive, etc., can solve the problems of overflowing glue, unable to control the overflowing glue, etc., and achieve the effect of solving the problem of glue overflowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

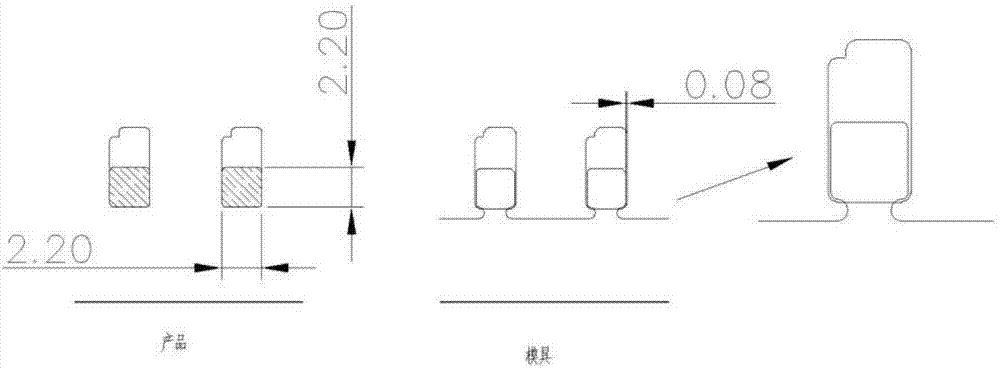

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

[0021] The zero-overflow glue processing method of the double-sided adhesive tape of the present invention comprises the following steps:

[0022] (1) Double-sided tape treatment: After the double-sided tape is cut into small rolls, put it into a plastic bag and seal it well, put it in the refrigerator / freezer to freeze, the temperature is 0-5°C, and the refrigeration time is more than 2 hours. The role of the plastic bag is to prevent the end of the double-sided adhesive from freezing. When used at room temperature, the ice melts and beads appear on the end of the film, which affects production and even affects the performance of the adhesive.

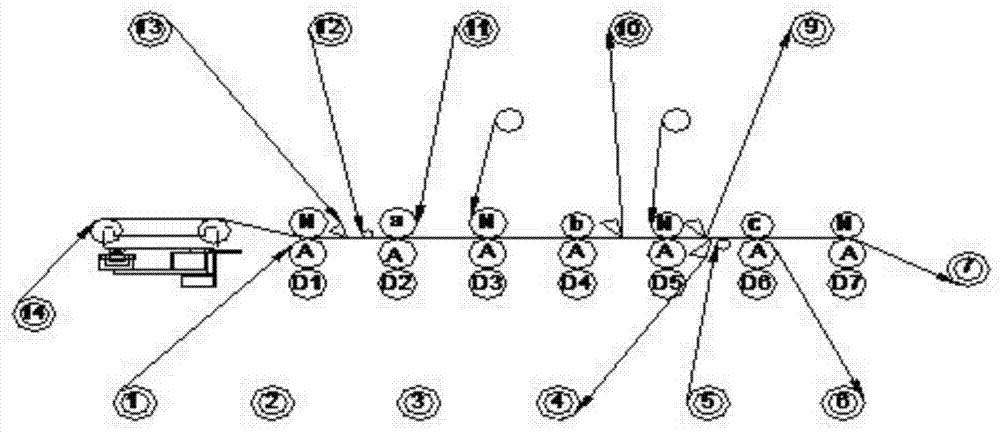

[0023] It is a convenient method for water glue that needs to be scraped. Fix the small roll of water glue on the rotating shaft, such as the feeding and unwin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| release force | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com