Intelligent fabric delivery system for steel cord cutting machine

A steel cord and cutting machine technology, which is applied to tires, other household appliances, household appliances, etc., can solve problems such as cord bending, tire balance, and poor uniformity, and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

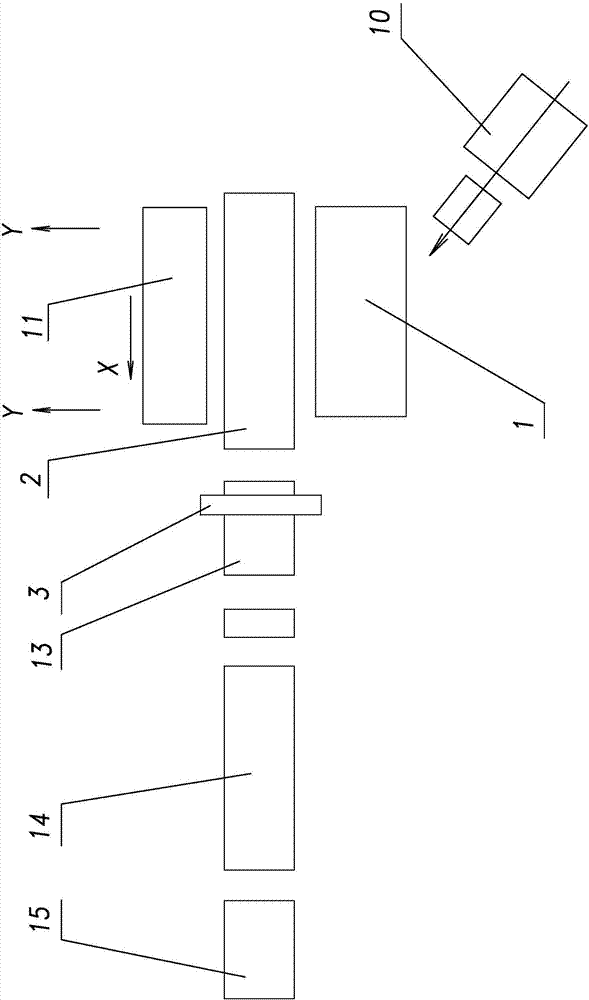

[0021] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

[0022] The production line process of steel cord cutting machine is: cord opening process (guiding device 10) - cutting process (cutting host 1) - conveying process (cord conveyor belt 2) - splicing process (splicing device 13) - glue bag Edge process (hemming device 14) - coiling process (coiling device 15), in the production mode of the normal control system, the curtain conveyor belt 2 conveys the cut curtain from the rear end (right end) to the front end (left end) fabric such as figure 1 shown.

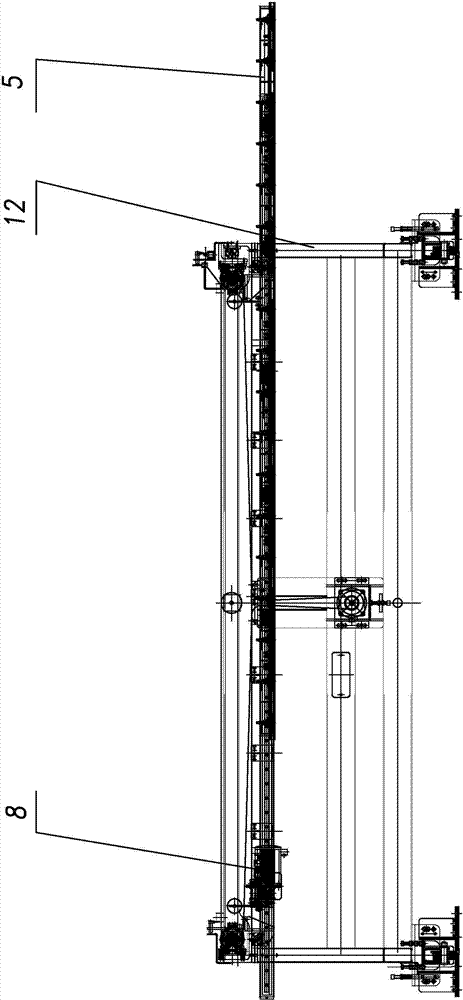

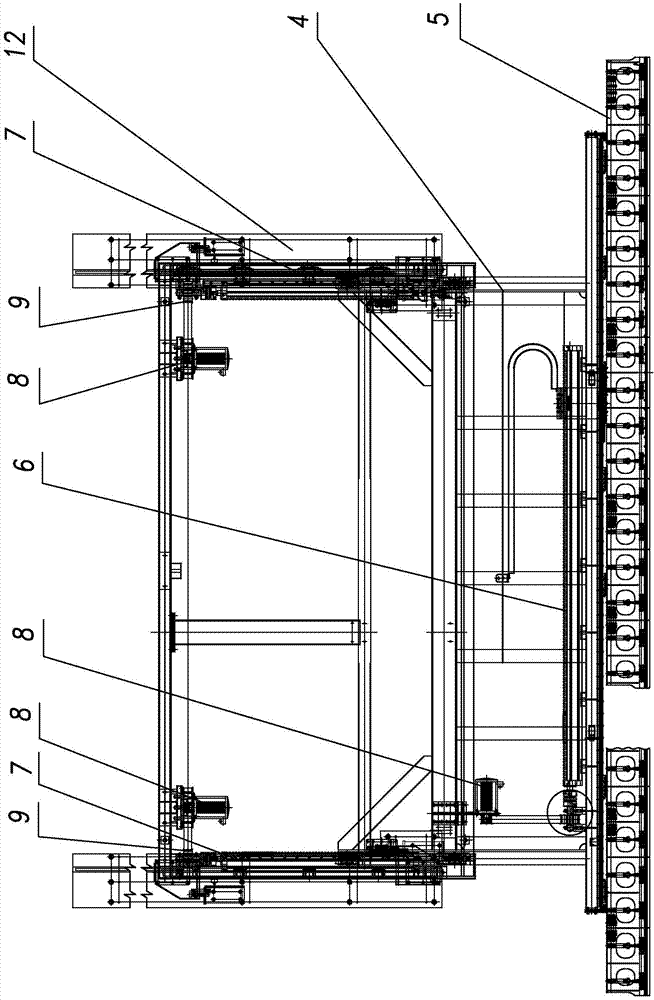

[0023] The intelligent fabric delivery system of the steel cord cutting machine of the present invention includes a traction fabric delivery device 11 and a (digital) online width measuring device 3 .

[0024] The traction and delivery device 11 is installed behind the cutting machine 1 and is mainly composed of a fabric delivery frame 4 and a cloth clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com