Accuracy assessment method for optical three-dimensional scanner

A scanner, three-dimensional technology, applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problems of qualitative regional deviation and the inability to accurately determine the measurement accuracy of three-dimensional scanners quantitatively, and achieve the effect of meeting the measurement requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

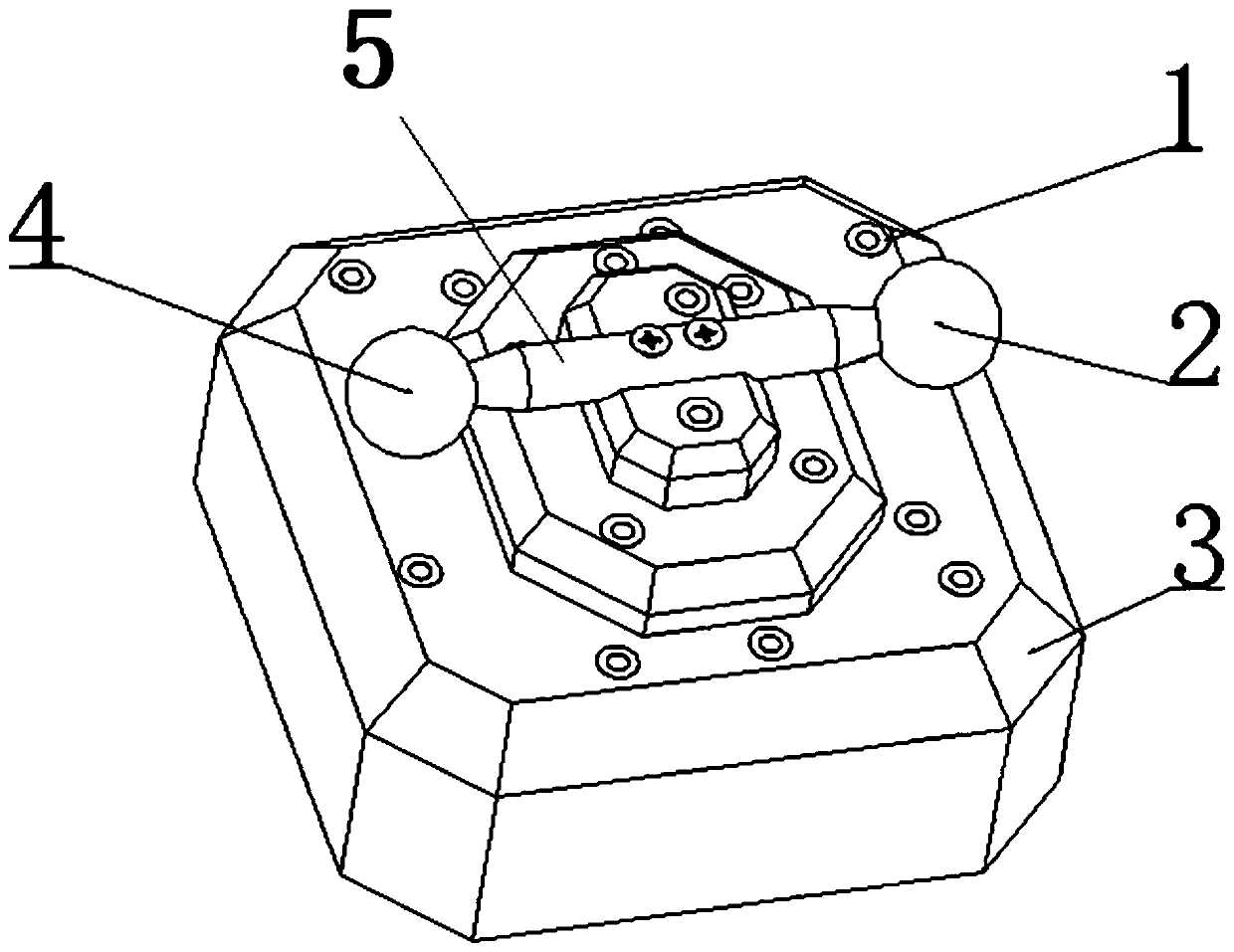

[0031] An accuracy evaluation method for an optical three-dimensional scanner, which is realized with custom-made standard parts, wherein, such as figure 1 As shown, the customized standard part includes a support platform 3, a connecting rod 5 and at least two dumbbell balls. Specifically, only two dumbbell balls are set in this embodiment, that is, the first dumbbell ball 2 and the second dumbbell ball 4, wherein , the second dumbbell ball 4 as a standard ball. The surface of the support platform 3 is provided with three layers of steps, and each step surface is designed with multiple inclined surfaces and multi-curved surfaces. Two dumbbell balls are connected by a connecting rod 5, and the connecting rod 5 is fixed on the topmost step surface of the surface of the support platform 3.

[0032] Preferably, the dumbbell balls can be designed with high precision, high hardness, and matte, and preferably the diameter of a single dumbbell ball is 4mm-60mm, the roundness is prefe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com