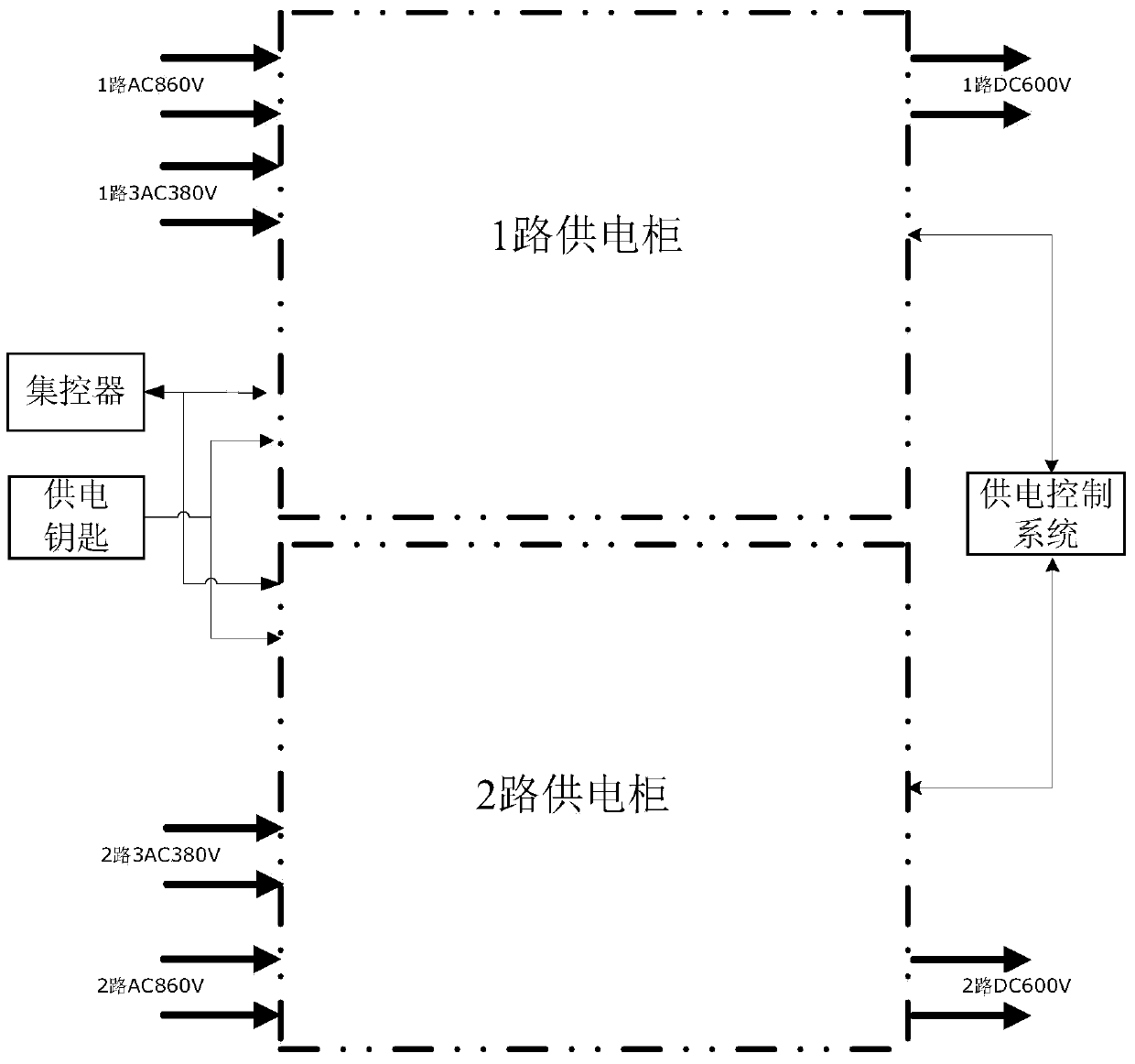

Train power supply control method and system for electric locomotives and train power supply equipment

A technology for power supply equipment and electric locomotives, applied in electric traction, electric vehicles, collectors, etc., can solve problems such as output voltage fluctuations, difficulty in starting, impact of train power supply equipment, etc., and achieve the effect of ensuring output voltage stability and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

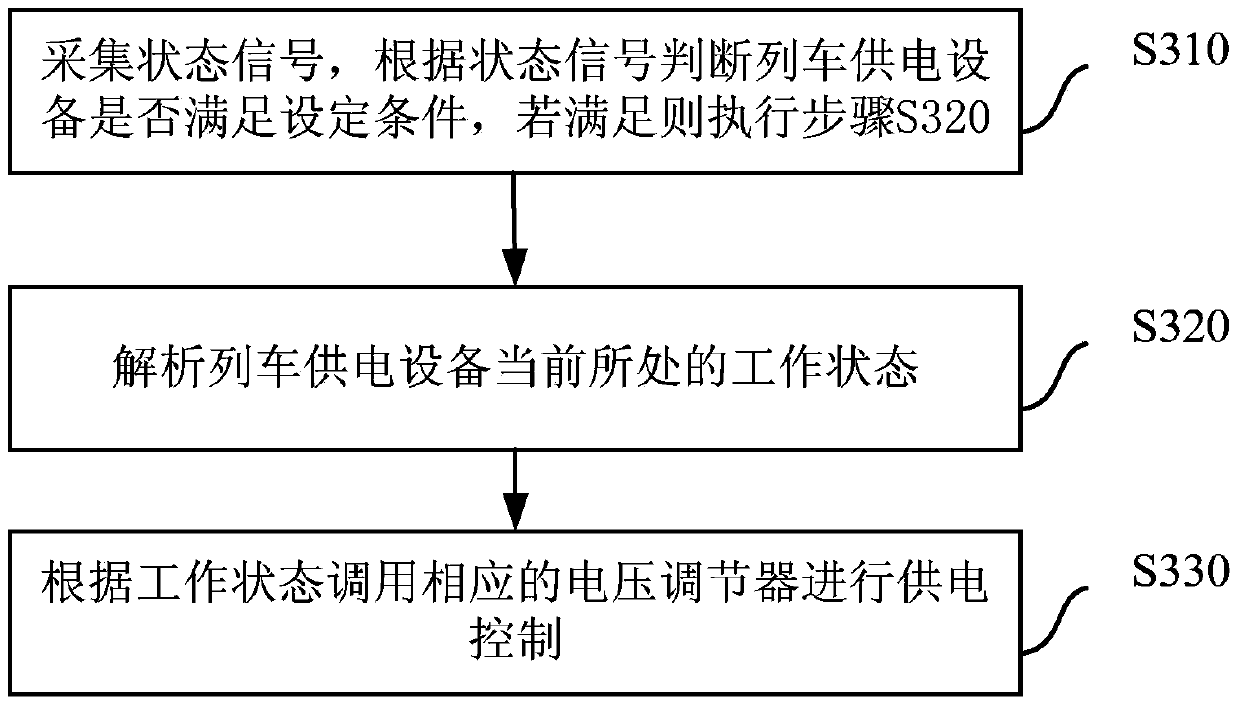

[0039] image 3 It is a schematic flow chart of a train power supply control method according to an embodiment of the present invention, and reference is made below image 3 to describe each step in detail.

[0040] Step S310, collecting status signals, judging whether the train power supply equipment satisfies the set conditions according to the status signals, and executing step S320 if so.

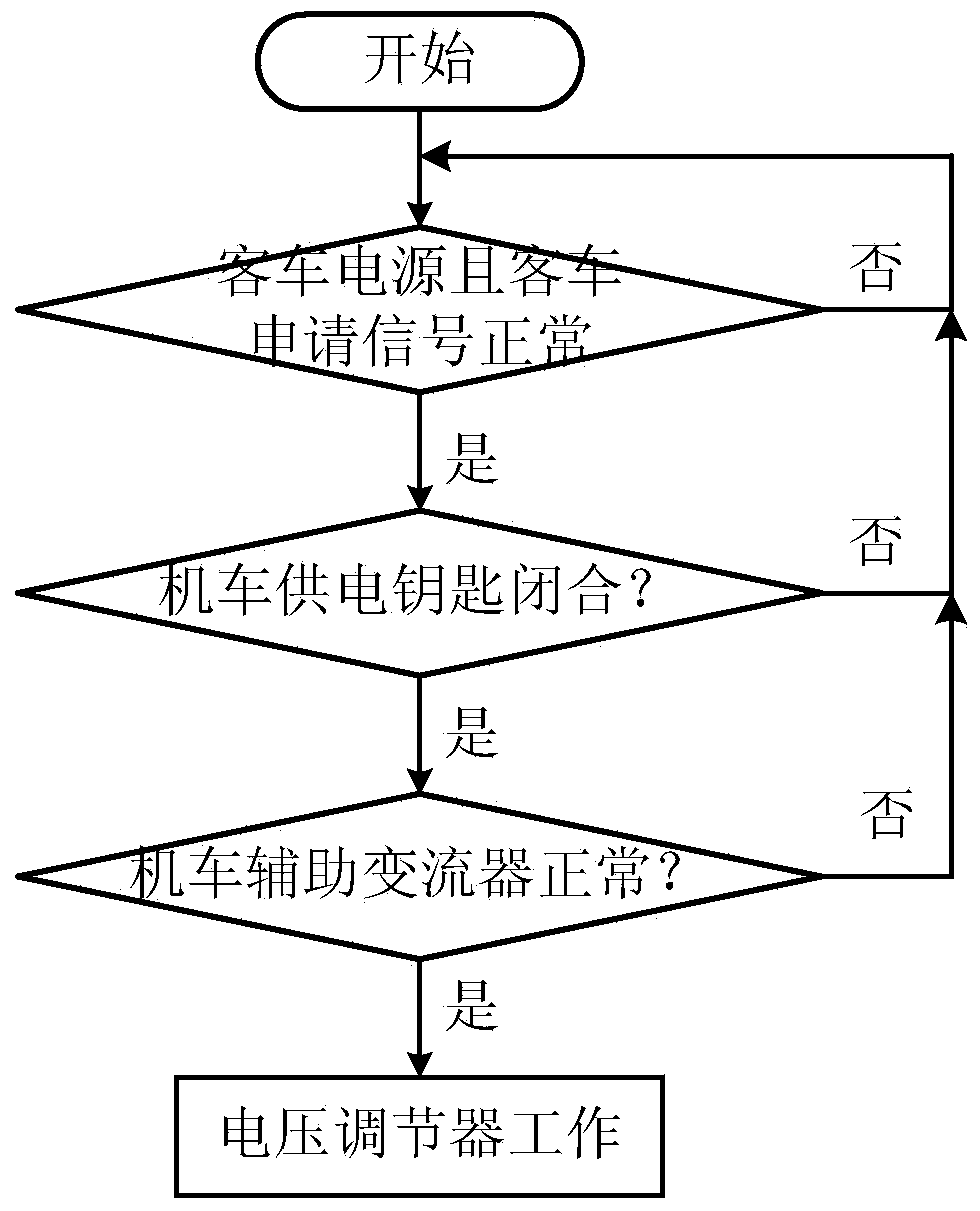

[0041] Specifically, the following setting conditions must be met at the same time when the train power supply equipment is started and put into operation:

[0042] ⑴The power supply signal of the passenger car is normal; ⑵The power supply application signal of the passenger car is normal; ⑶The power supply key of the electric locomotive is closed; ⑷The auxiliary converte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com