Paying-off fixing device

A technology of fixing device and line, applied in the direction of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve problems such as wear and tear of finished enameled wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

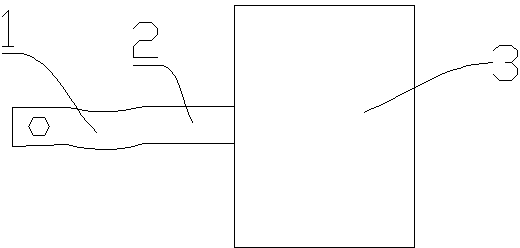

[0011] Such as figure 1 , figure 2 As shown, this embodiment includes a thread guide 3 , a connecting rod 2 and a clamp 1 , one end of the connecting rod 2 is connected to the clamp 1 , and the other end is connected to the thread guide 3 .

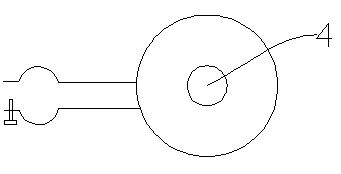

[0012] In order to reduce the swinging range of the enameled wire and prevent the enameled wire from wearing and tearing, the wire traveler 3 is cylindrical, with an axial through hole 4 in the middle, and the inner wall of the through hole 4 is covered with a layer of felt.

[0013] The present invention uses method as follows:

[0014] Install the wire-releasing fixture above the damaged enameled wire take-up reel, the wire guide 3 is on the axial center line of the take-up reel, pass the enameled wire end through the through-hole 4 of the wire guide, and then connect it to the take-up reel to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com