Spring piece component, automatic mounting and demounting connecting structure and touch all-in-one machine

A technology of spring sheets and components, which is applied in the field of touch all-in-one machines, can solve the problems of low disassembly and assembly efficiency, inconvenient disassembly and reassembly of the surface shell and bottom frame, and time-consuming, etc., so as to reduce the difficulty of installation and disassembly, and facilitate the disassembly and assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

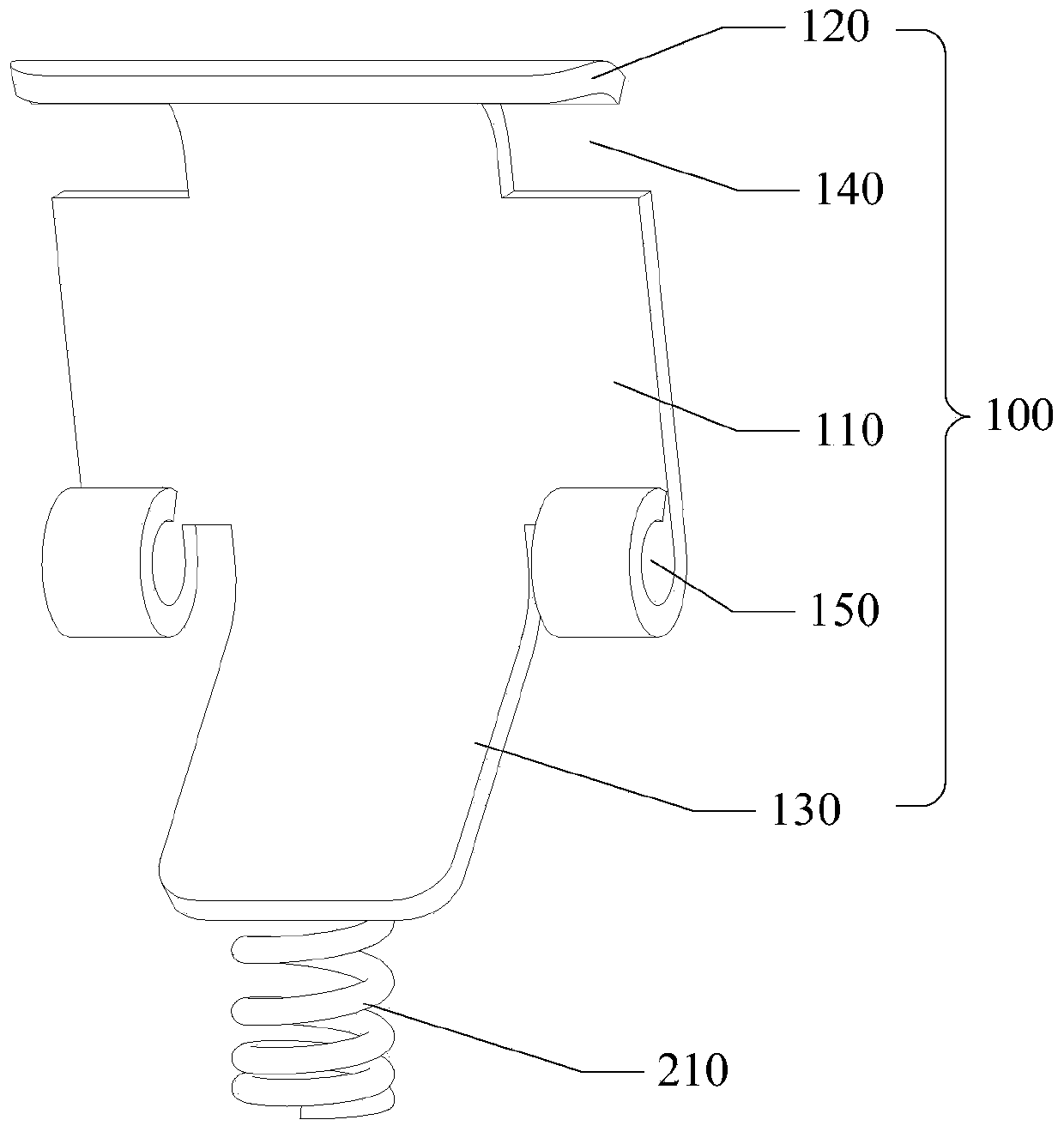

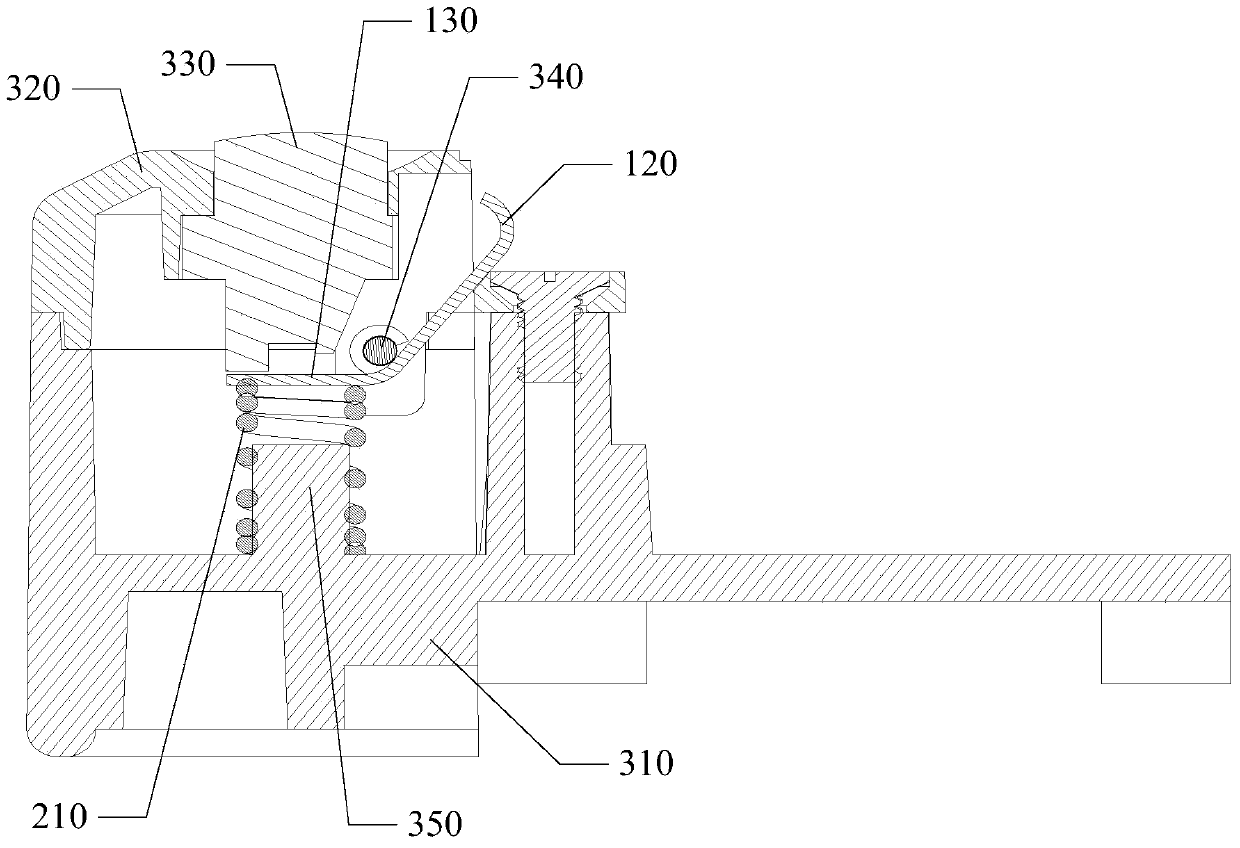

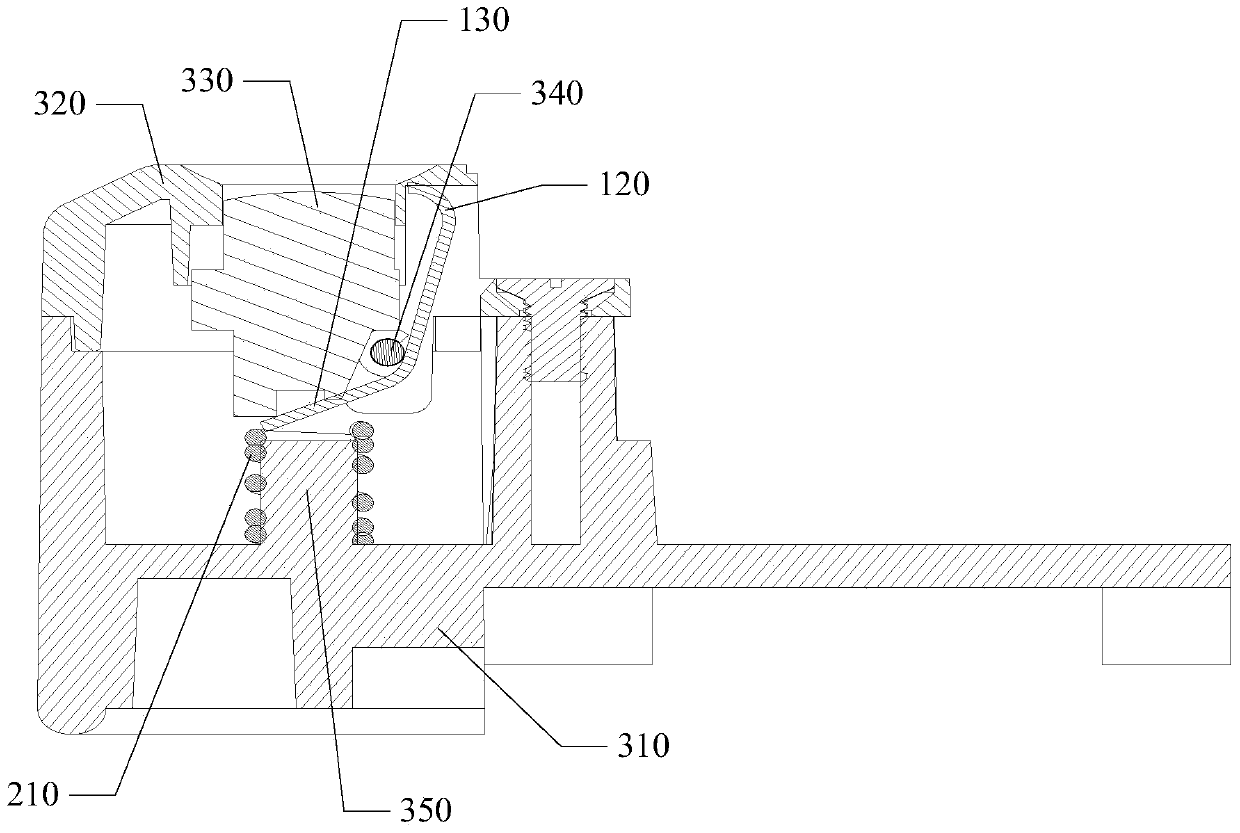

[0024] like Figure 1 to Figure 3 as shown, figure 1 It is a structural schematic diagram of the first embodiment of the leaf spring assembly of the present invention, figure 2 It is a structural schematic diagram of the spring leaf assembly in the assembly position in the first embodiment of the automatic disassembly and assembly connection structure of the present invention, image 3 It is a structural schematic diagram of the spring leaf assembly in the dismounting position in the first embodiment of the automatic disassembly and assembly connection structure of the present invention.

[0025] The leaf spring assembly mentioned in this embodiment includes a leaf spring 100. The leaf spring 100 includes a body 110. One end of the body 110 is bent inward to form a clamping portion 120, and the other end of the bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com