Auto-injector

An automatic injection and syringe technology, applied in the direction of automatic injectors, syringes, hypodermic injection equipment, etc., can solve problems such as strong impact, and achieve the effects of reducing production costs, reducing the number of parts, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0151] The term "slope joint" in this specification is a joint between two parts at least one of which has a slope that engages the other so that when the two parts are pushed against each other in the axial direction One of the two parts deflects sideways when in contact with each other, assuming that this part is not prevented from deflecting sideways.

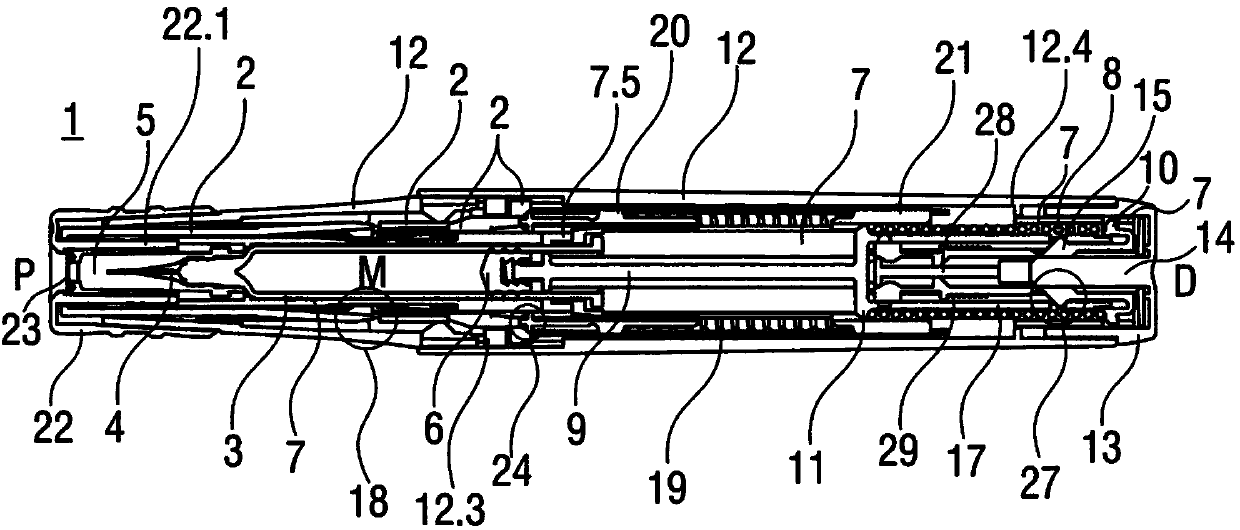

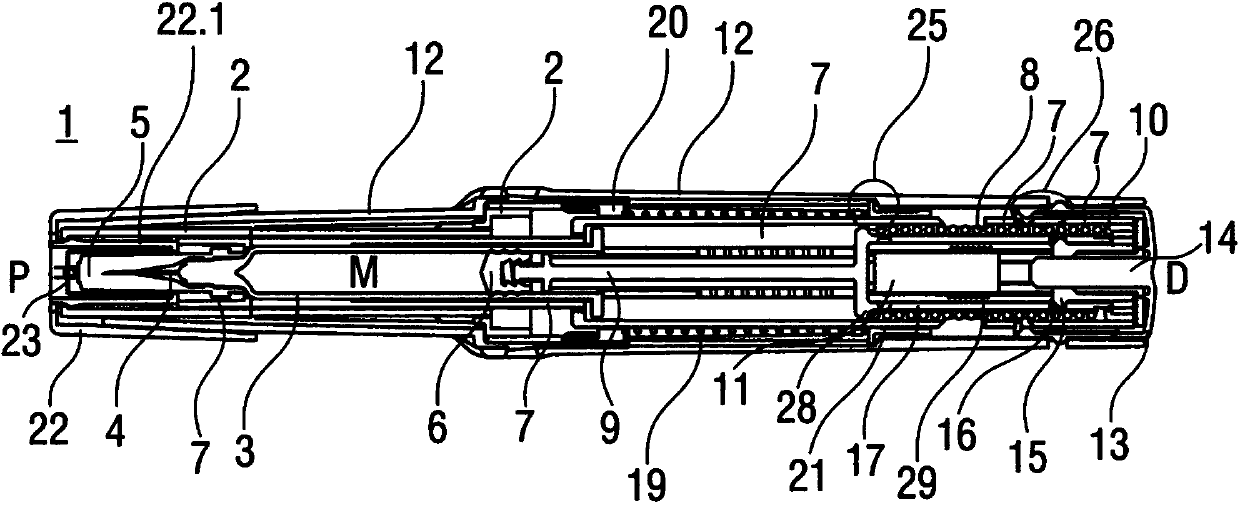

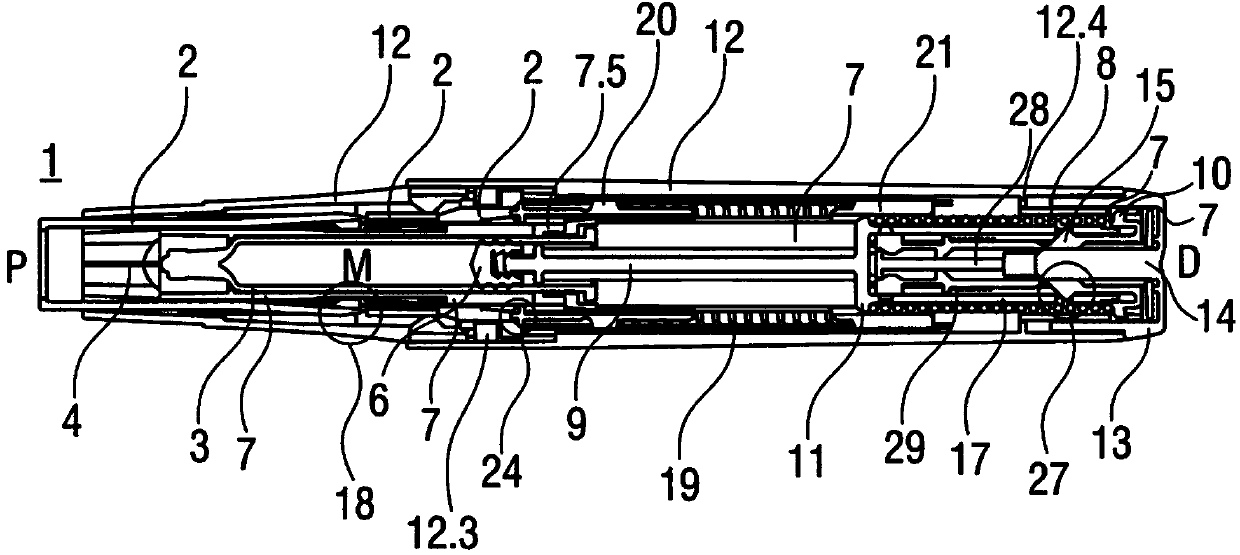

[0152] Figure 1A and 1B Two longitudinal sections of the automatic injection device 1 are shown in different sections, which are rotated by approximately 90° relative to each other, the starting state of the automatic injection device 1 before the start of the injection. The automatic injection device 1 comprises a housing 2 . In the following, the frame 2 is generally considered to be fixed in position, so the movements of other components are described relative to the frame 2 . A syringe 3 with a hollow injection needle 4 , for example a Hypak syringe, is arranged on the proximal part of the automatic injection device 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap