Tea-leaf picker provided with damping device and internal combustion engine, and working method

A technology for internal combustion engines and tea picking machines, which is applied to picking machines, shock absorbers, springs/shock absorbers, etc., which can solve problems such as heavy engine weight, operator discomfort, and back frame vibration, and achieve good shock absorption and detection High precision, reduce the effect of back frame vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

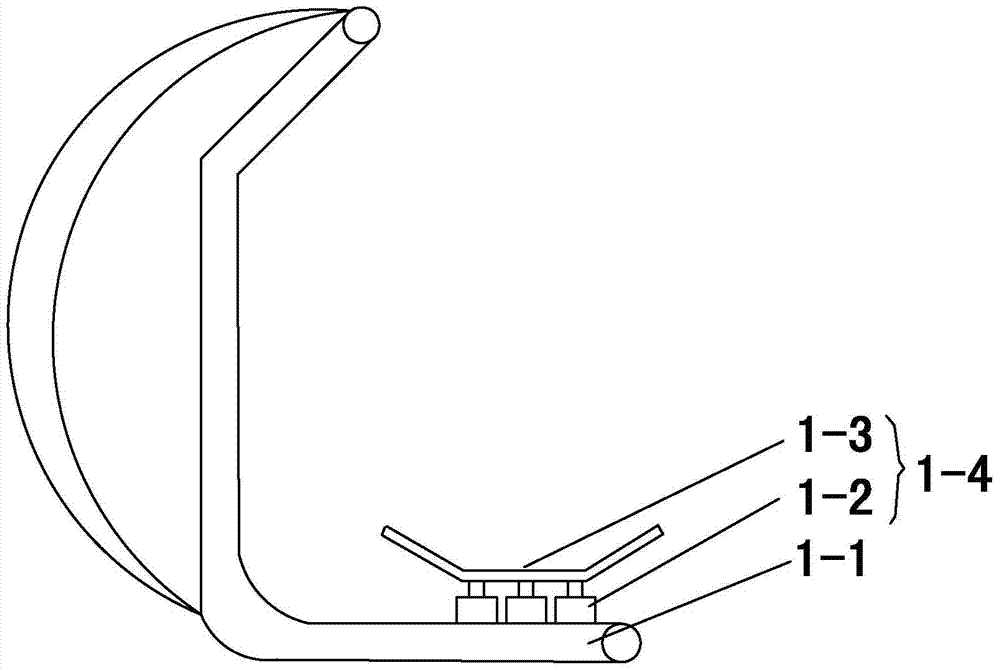

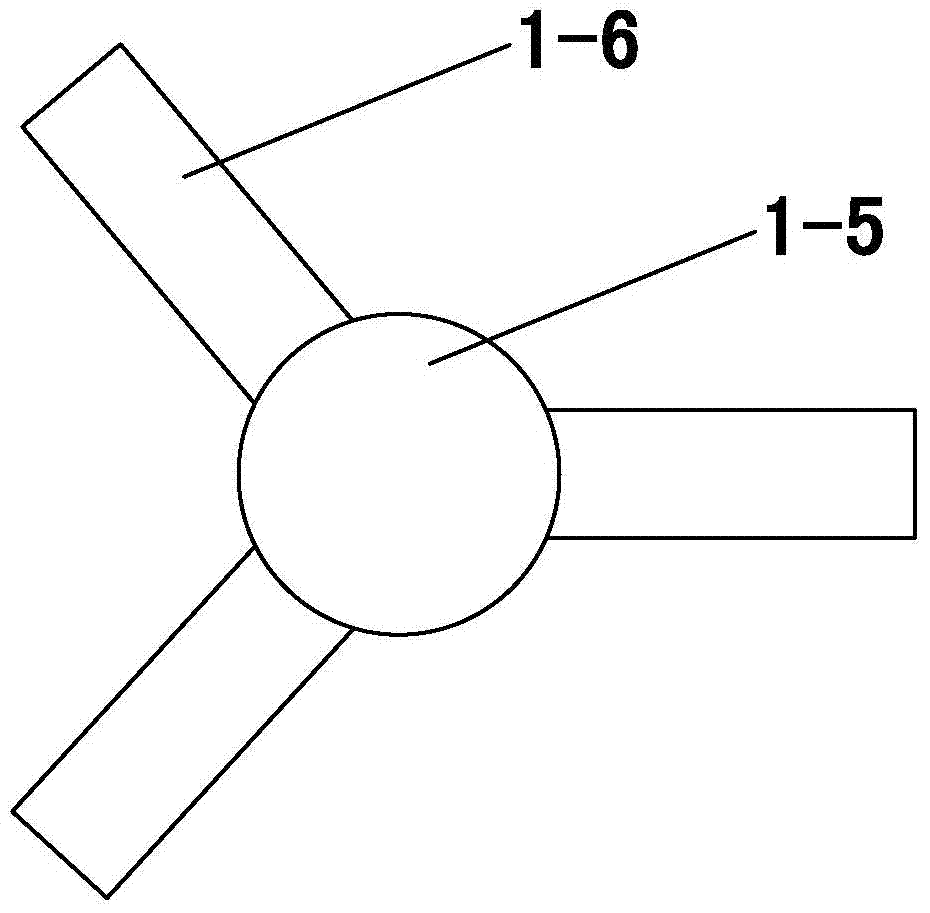

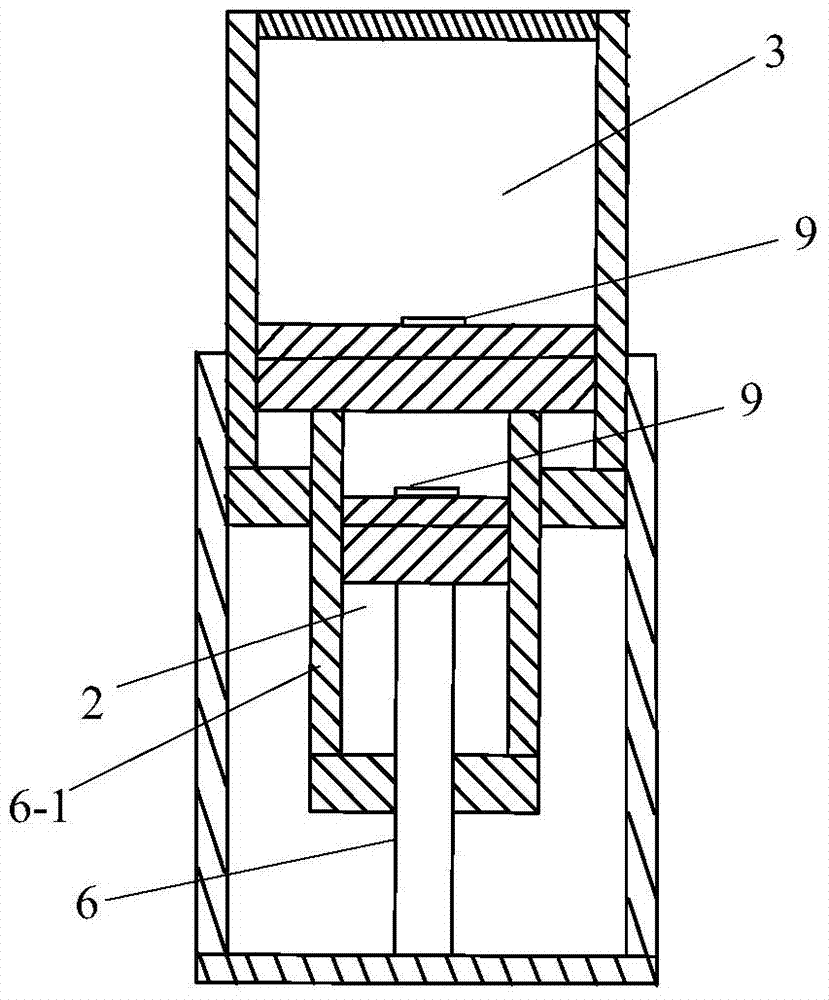

[0040] See figure 1 with figure 2, a tea picking machine using an internal combustion engine, comprising: an internal combustion engine, a gearbox used to control the rotation of tea picking blades, the internal combustion engine is connected to the gearbox in transmission; a back frame is also included, and the back frame includes: a base 1-1, The base 1-1 is provided with a shock absorber 1-4 for mitigating the vibration of the internal combustion engine; the shock absorber 1-4 includes: at least three shock absorbers 1-2 are symmetrically distributed around the center of the base for supporting the internal combustion engine A support frame 1-3, the support frame 1-3 includes: a support base 1-5, at least three arc-shaped support arms 1-6 for supporting the internal combustion engine evenly distributed on the support base 1-5; The two ends of the shock absorber 1-2 are respectively fixedly connected with the upper end surface of the base 1-1 and the lower end surface of t...

Embodiment 2

[0053] The working method of shock absorber in the tea picking machine that adopts internal combustion engine based on above-mentioned embodiment 1 comprises:

[0054] When the engine is working, the engine generates up and down pressure due to vibration, and the processor module judges the value of the up and down pressure generated by the engine according to the medium pressure detected by the pressure sensor, so as to adjust the medium back and forth in the corresponding cylinder Flow, and then control the movement speed of the piston body assembly;

[0055] Wherein, the processor presets a graded damping threshold, and if the currently detected medium pressure value is not higher than the graded damping threshold, the processor controls the pressure of the piston body assembly 7 in the first stage shock absorber 2. The second piston body 7-2 rotates to open the through hole 7-3, thereby opening the first stage shock absorber 2, and at the same time, the processor controls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com