Multiple fermentation process for soybean sauce

A multi-fermentation and soy sauce technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of prolonging the fermentation cycle and the lack of mellow ester aroma of the product, and achieve the effect of natural flavor, thick and long taste, and thick body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

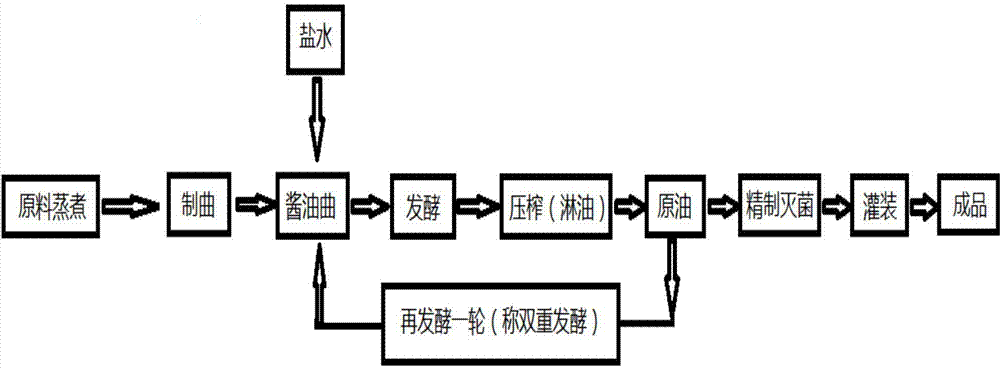

[0025] Such as figure 1 As shown, the multi-fermentation process of the present invention comprises the steps of cooling the raw materials after high-temperature cooking, adding koji seeds for koji making, then mixing and fermenting with salt water, pressing or pouring oil after fermentation to produce soy sauce crude oil, and then squeezing or pouring The oiled soy sauce crude oil is mixed with soy sauce koji to enter the next round of fermentation, and then squeezed or poured with oil, and so on, and finally refined, sterilized, and filled to become a finished soy sauce. The specific process is as follows:

[0026] (1) Raw material cooking: the soy sauce raw material is cooked at high temperature and then cooled down;

[0027] (2) Koji making: add koji seeds to the clinker after high-temperature cooking and cooling to make soy sauce koji;

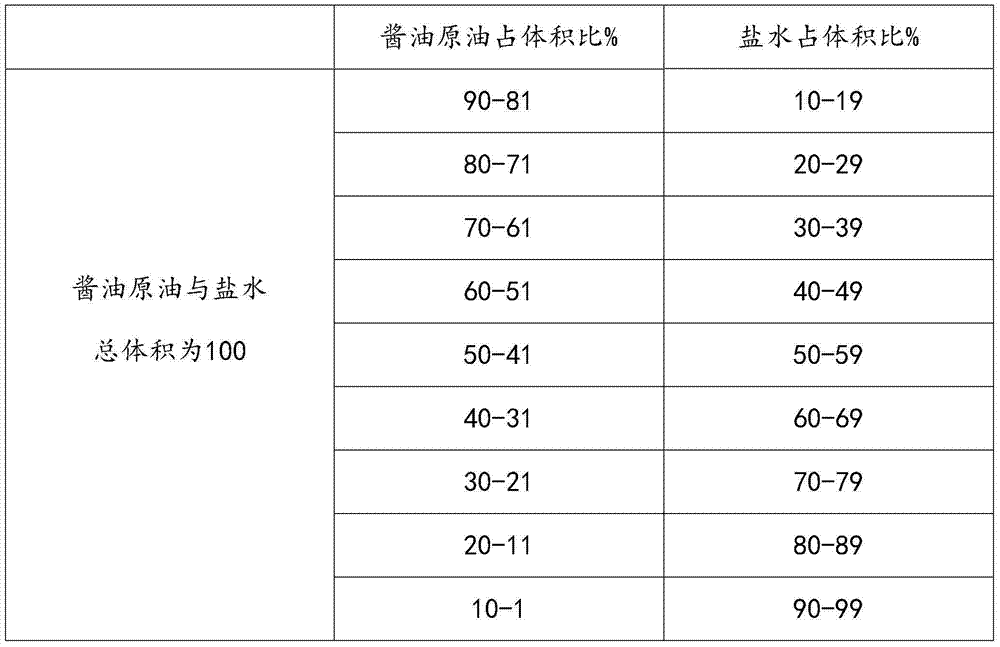

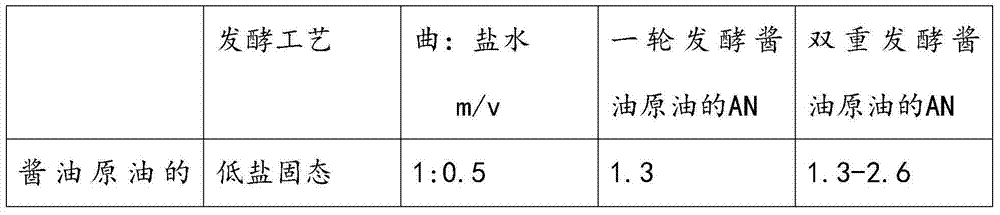

[0028] (3) Fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com