Method and system for correcting deviation of needle printer

A technology of dot matrix printers and calibration methods, which is applied to printing devices, printing, transfer materials, etc., can solve the problems of dot matrix printer deviation, printing quality and printing efficiency, and achieve the effect of improving printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

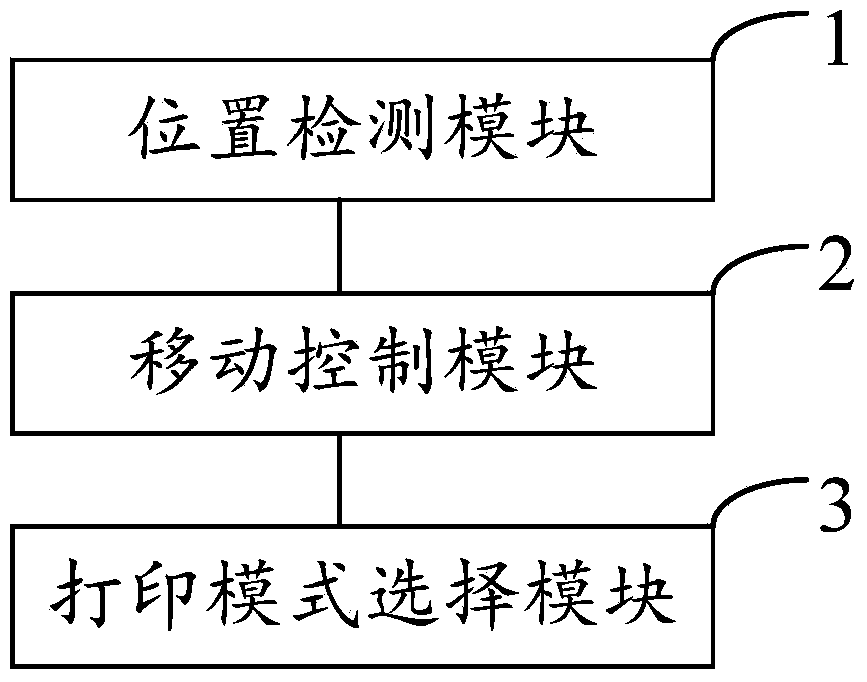

[0043] combine figure 1 and figure 2 , the present invention proposes a first embodiment, a method for correcting the deviation of a stylus printer, including the following steps.

[0044] S1, detecting the current position of the word car;

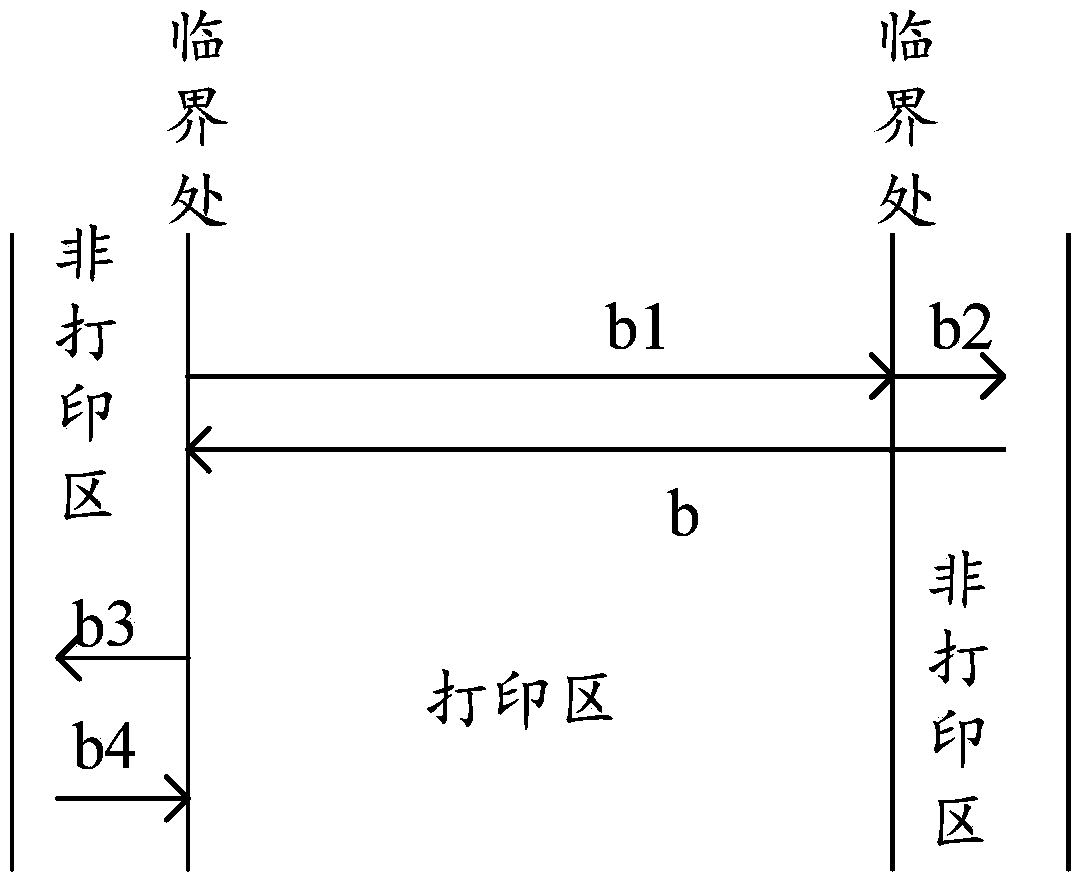

[0045] If the current position of the character car is in the printing area or the critical place, the character car moves to the non-printing area, and steps S11 and S12 are executed in sequence;

[0046] If the current position of the character car is in the non-printing area, the character car moves to the printing area, and steps S12 and S11 are executed in sequence;

[0047] Wherein, the critical point is the junction of the printing area and the non-printing area.

[0048] S11, the character carriage moves back and forth in the non-printing area, records the distance that the character carriage moves back and forth and feeds the paper, and calculates the first error produced by the back and forth movement of the paper;

[0049]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com