Service braking system of four-axle chassis and crane with same

A technology of driving brake and control system, which is applied in the direction of brake transmission, brakes, vehicle components, etc., can solve the problems of four-axle locking, easy lock-up, and second-axle locking, etc., and achieve the safety of driving brake Guaranteeing and improving handling stability and driving brake safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

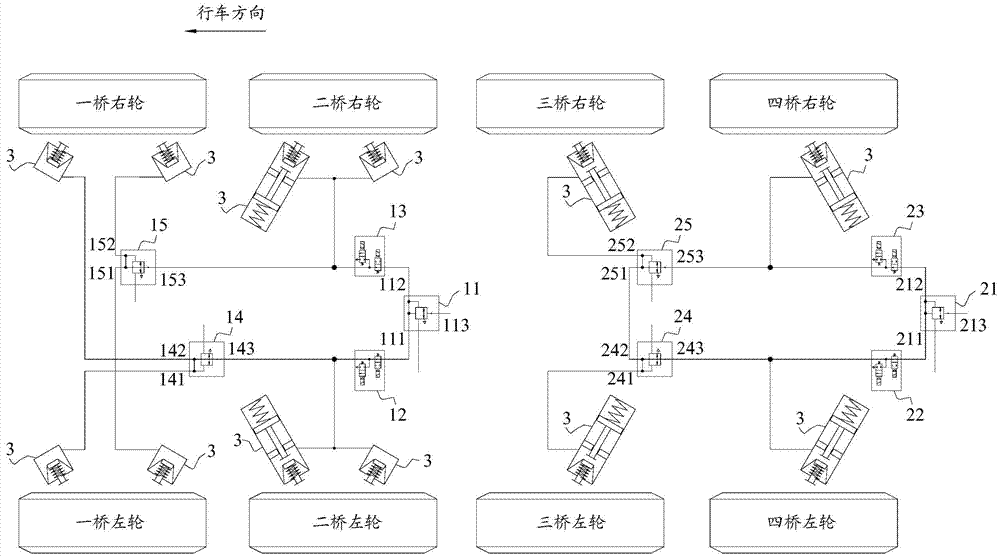

[0022] The core of the present invention is to provide a service braking control system for the four-axle chassis. The system optimizes the configuration of the service braking system in combination with the characteristics of the four-axle chassis, which can completely avoid abnormal locks of the second and fourth axles. The dead phenomenon provides a reliable guarantee for the safety and stability of the vehicle. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

[0023] See figure 1 , which is a schematic diagram of the principle of the service brake control system of the four-axle chassis described in this embodiment.

[0024] As shown in the figure, from front to back along the driving direction are the first bridge, the second bridge, the third bridge and the fourth bridge. There are two brake air chambers 3 on the left and right sides of the bridge and the second axle respectively, and one brake air chamber 3 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com