Radial forging non-rotating forging method

A technology of rotary forging and radial forging machine, which is applied in the field of forging and can solve problems such as insufficient forging performance of radial forging machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

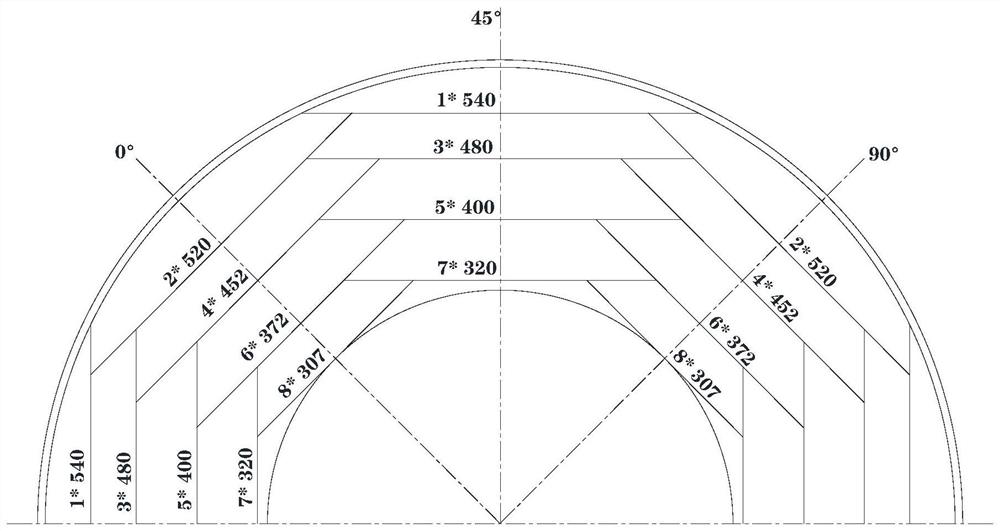

Image

Examples

Embodiment 1

[0051] The incoming material is: 5.4t octagonal ingot, steel type 316L; the finished product is 307 round, the heating temperature is 1210°C±10°C, and after 6.5 hours of heat preservation, it is released to the 16MN diameter forging machine for forging (currently the forging range of the 16MN hydraulic diameter forging machine is 300- 500mm), the specific forging steps are as follows:

[0052] 1) Rotation synchronous forging

[0053] The first pass of chamfering forging, one group and two groups of hammer heads rotate synchronously forging, the rotation angle is 22.5°, the feed is 60mm, the forging position of the manipulator is "0°, the forging frequency is 1300ms / time, and the forging specification is up to 660mm;

[0054] In the second pass, the first group and the second group of hammerheads rotate synchronously forging, the rotation angle is 30°, the feed is 60mm, the forging position of the manipulator is "0°, the forging frequency is 950ms / time, and the approximate circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com