Central corner angle needle-dividing knife

A needle-knife, edge-and-angle technology, applied in the field of parts and components, can solve problems such as lowering production efficiency, unfavorable long-term development, and affecting socks knitting, and achieves the effect of improving quality and simple and exquisite structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

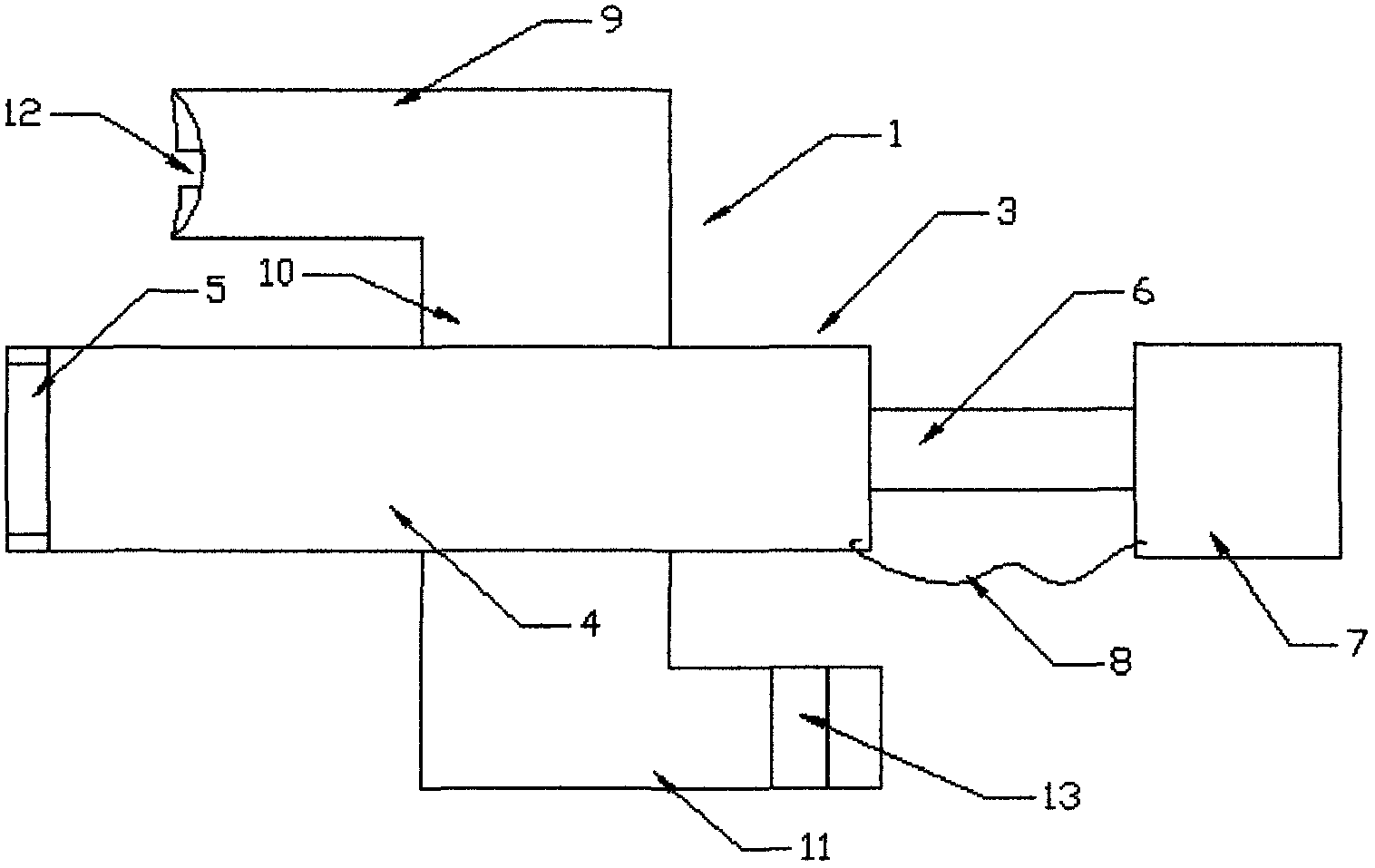

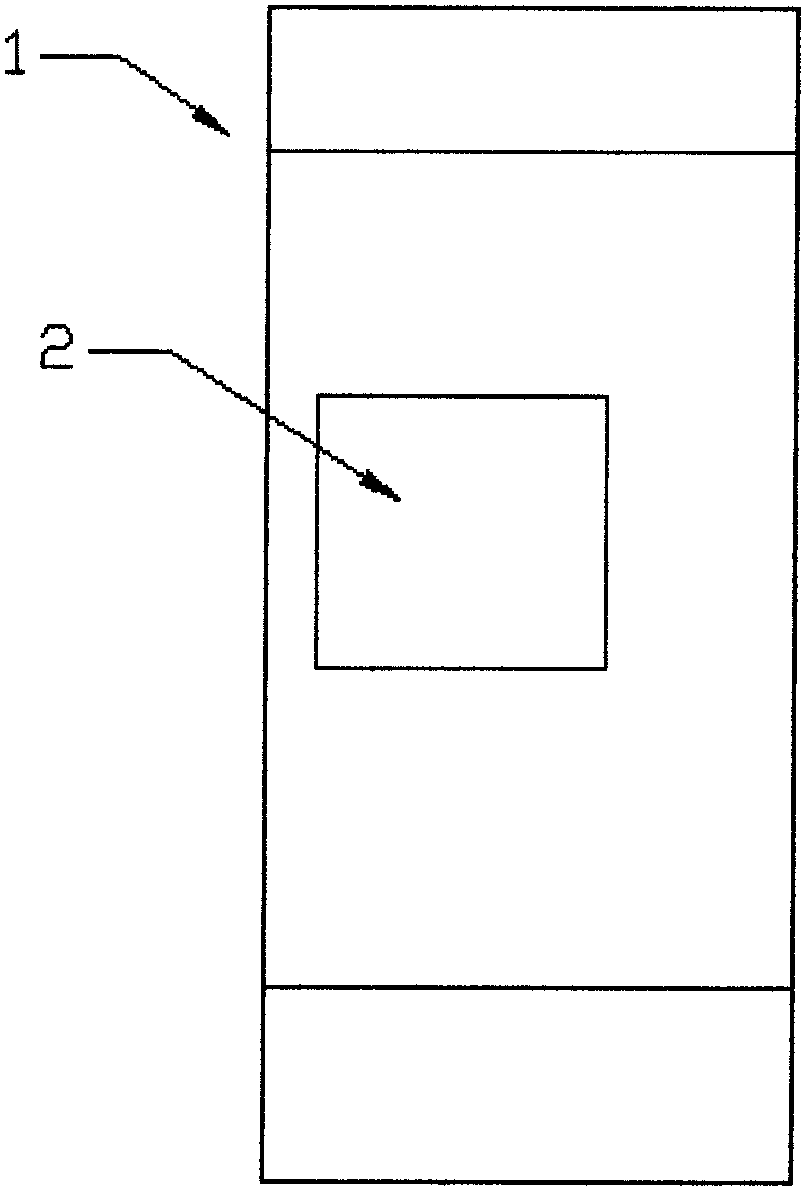

[0024] Such as Figure 1 to Figure 2 As shown, the present invention relates to a middle-edged minute needle knife, which is characterized in that: it includes a fixing part 1, a square through hole 2 is arranged on the fixing part 1, and a minute needle knife 3 is arranged on the square through hole 2, and the minute needle knife 3 comprises blade body 4, is provided with the cutter body 5 that cross section is trapezoid at the front end of blade body 4, is provided with a fixing hole at the lower right end of blade body 4, is connected with ejector rod 6 at the right end of blade body 4, at the other end of ejector rod 6 A cylinder 7 is provided, and a spring 8 is arranged between the cylinder 7 and the fixing hole.

[0025] It is further provided that the fixing member 1 is Z-shaped, including an upper end 9 , a middle end 10 and a lower end 11 integrally formed.

[0026] It is further provided that the end of the upper end 9 is a slightly narrowed mouth, the front end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com