Punching equipment for antenna reflective surface punching

A reflective surface and punching technology, which is applied in the field of antenna processing, can solve the problems of difficult installation of radome, complex processing technology, inaccurate installation hole angle, position and aperture size, etc., and achieve low manufacturing cost, simple process and simple structure subtle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

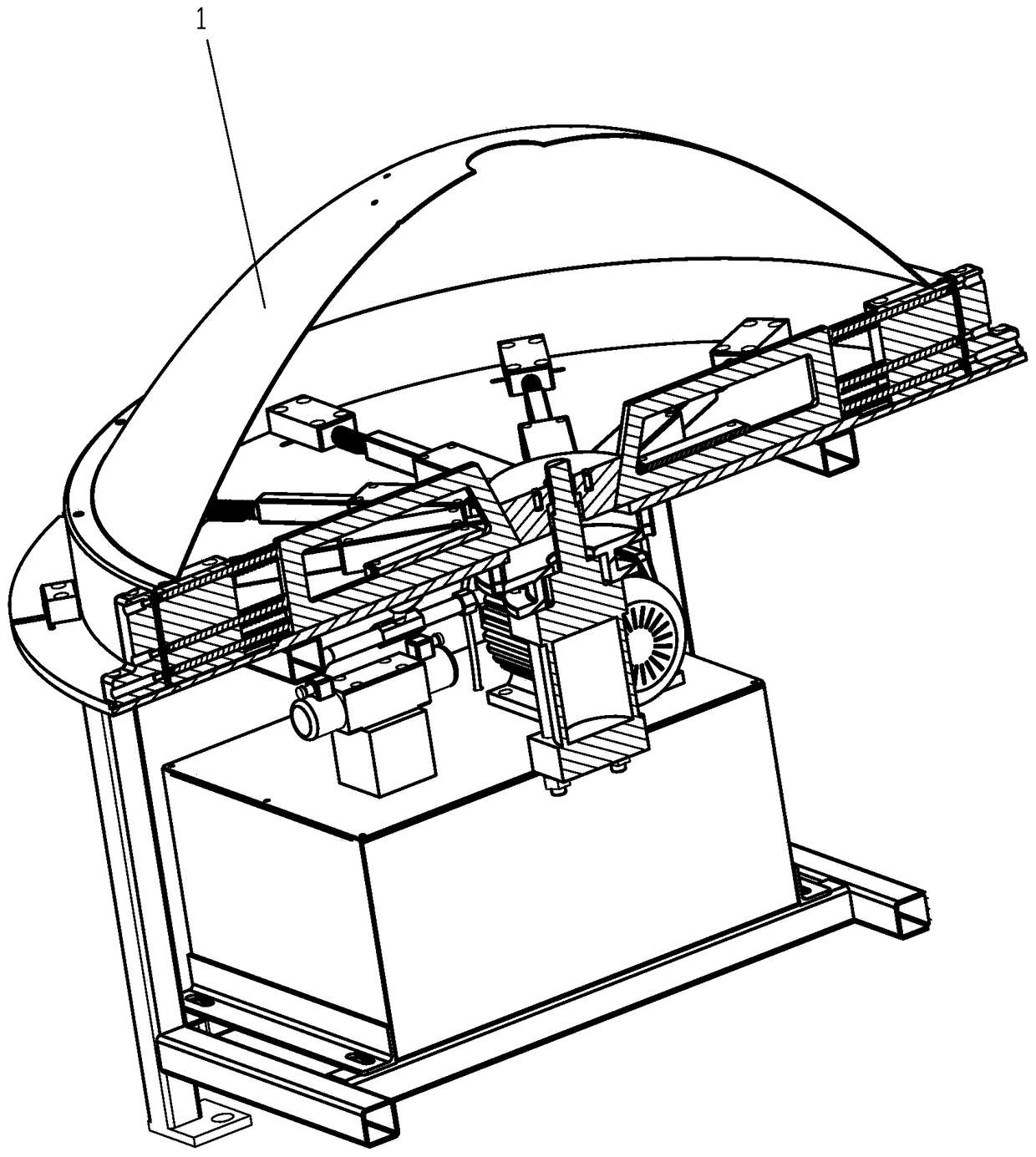

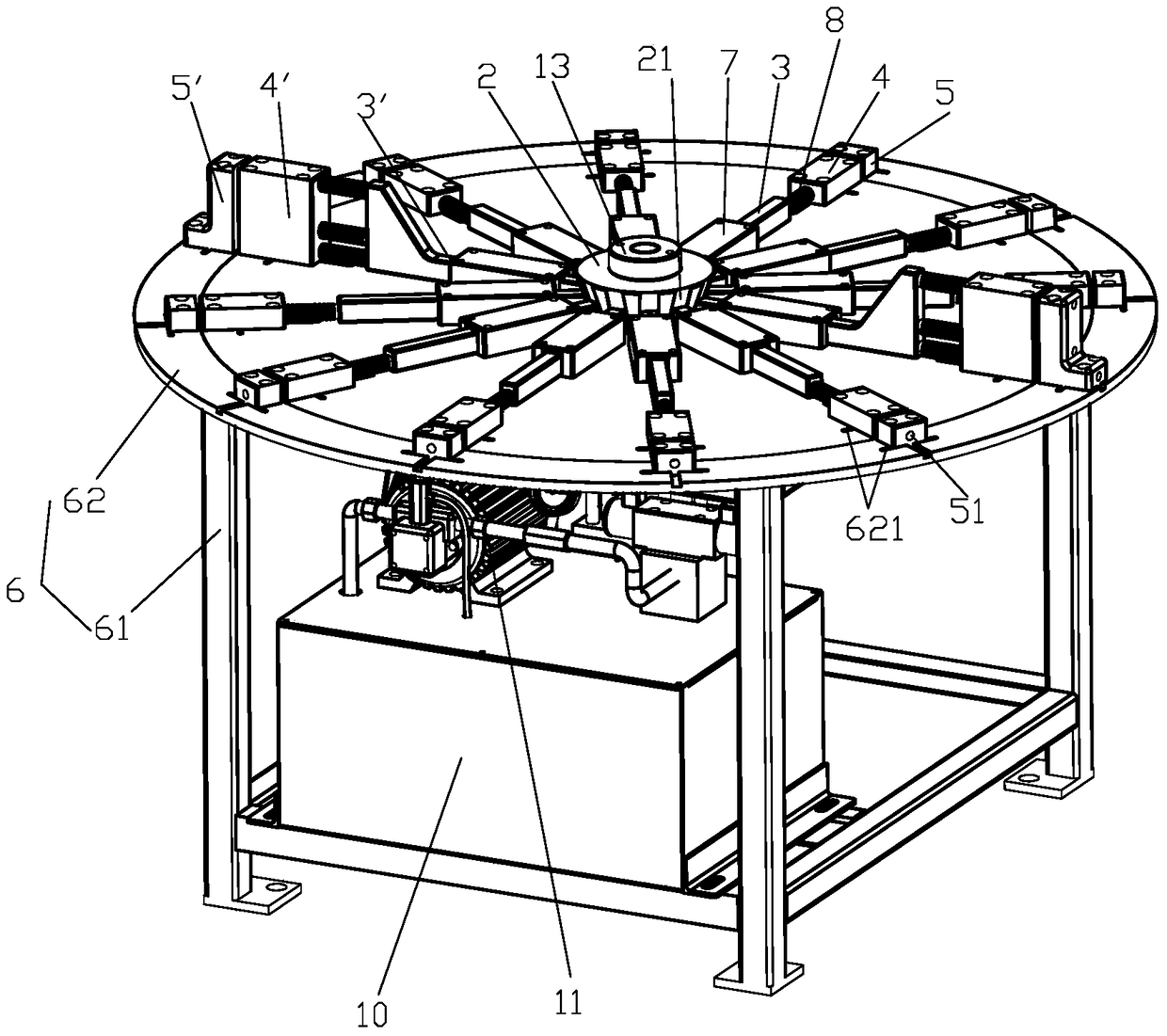

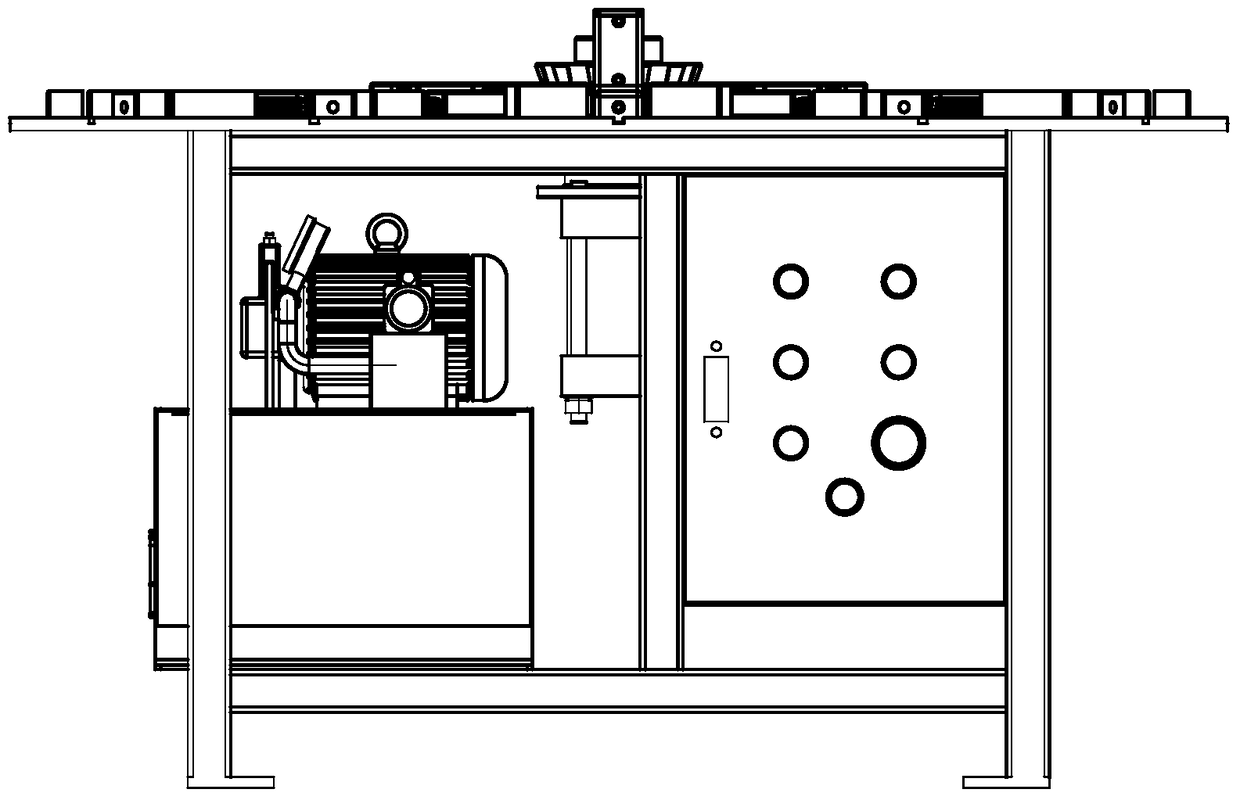

[0026] see Figure 1 to Figure 6 , the punching equipment of the embodiment of the present invention is especially suitable for punching the antenna reflective surface 1 with straight sides. The punching equipment includes: an output shaft that can be driven by a power source; A plurality of punching pins 3 that are cooperating with each other and can expand and contract along their own length direction under the drive of the output shaft; multiple sets of punches 4 and dies 5 with the same number as punches 3, each set of punches 4 and dies 5 , the punch 4 and the die 5 are relatively spaced apart, and are used to clamp and fix the antenna reflection surface 1, wherein the punch 4 and the die 5 are provided with aligned through holes 41, 51 for the punch pins 3 to pass through from the inside to the outside in sequence Then the antenna reflection su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com