Diesel engine drain valve

A technology of diesel engine and water drain valve, applied in the field of diesel engine parts, can solve the problems of freezing crack and loss of diesel engine cooling system parts, and achieve the effect of preventing freezing crack and overcoming volume expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

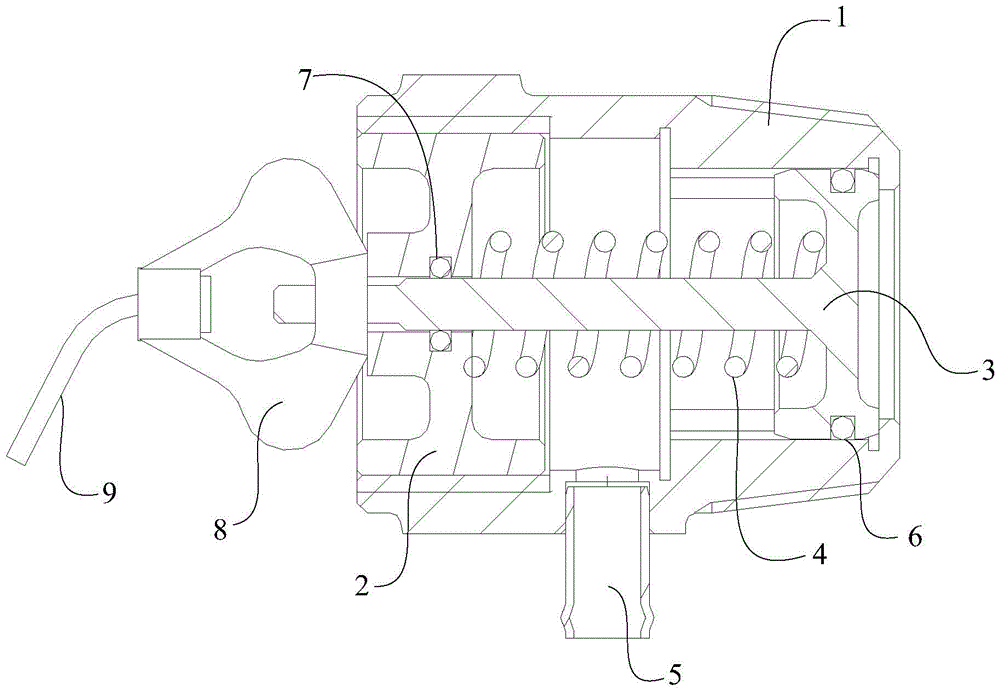

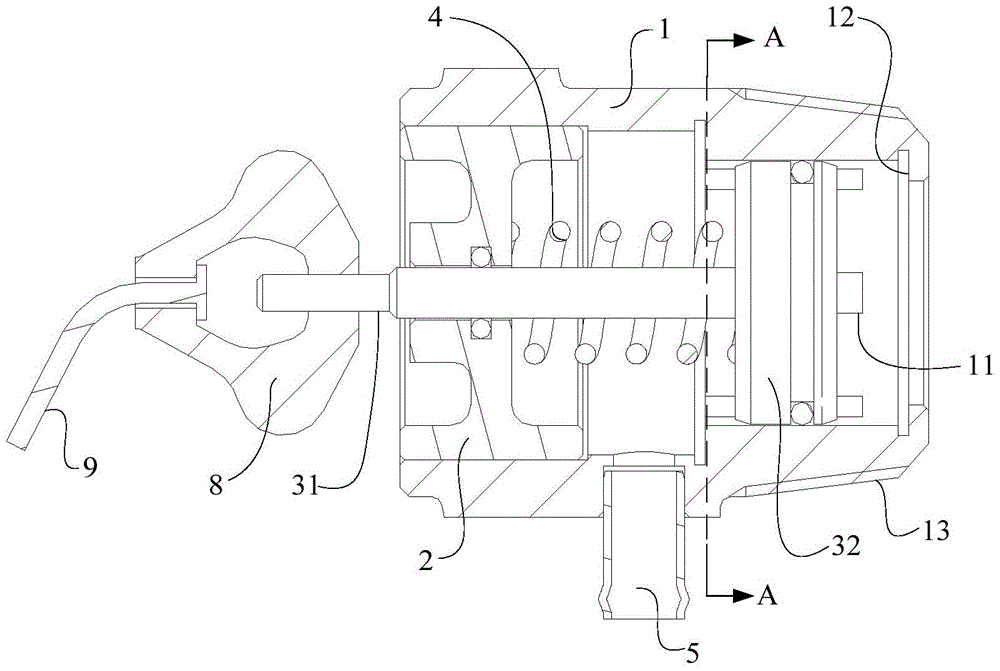

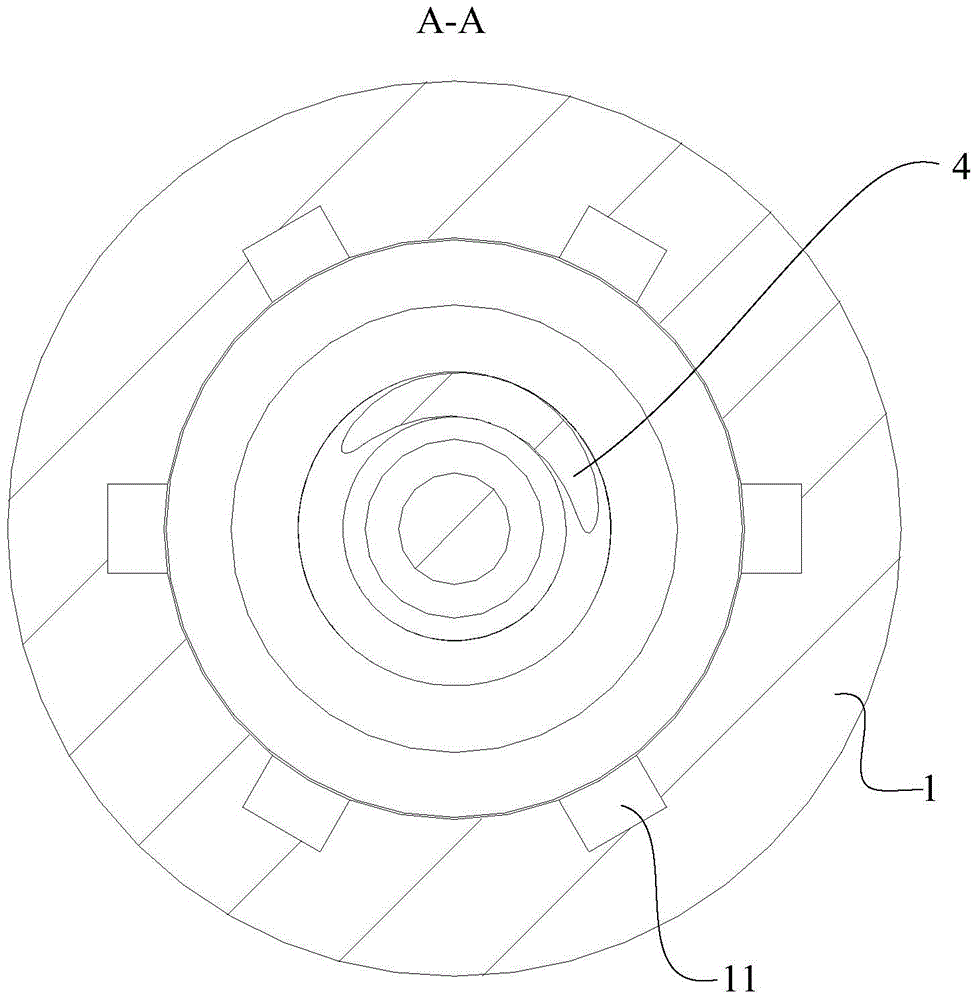

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0022] The diesel engine drain valve of the present invention not only guarantees the function of draining water to the diesel engine, but also has the effect of preventing the parts of the diesel engine from being frozen and cracked. When there are solid ice crystals, the volume of the cooling water increases. At this time, driven by the increase in the liquid-solid conversion volume of the cooling water, the valve plate slides against the return spring, the valve opens, and the diversion groove communicates with the engine cooling water. All the converted cooling water flows out through the diversion groove and flows into the external environment through the drain pipe. In this way, in the low temperature environment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com