Fuel-gas fast anti-freezing water heater with automatic draining function

A technology for automatic drainage and water heaters, which is applied to fluid heaters, lighting and heating equipment, etc., and can solve problems such as waste and failure of water heaters to prevent freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

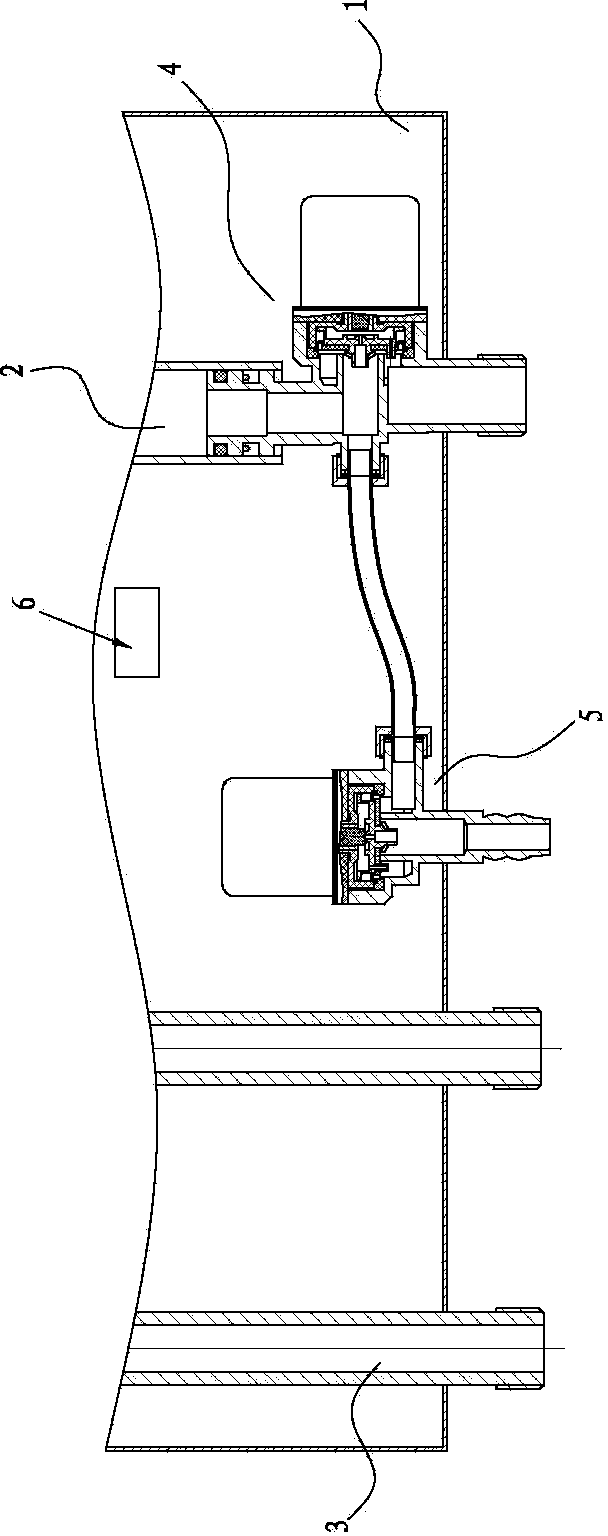

[0021] Such as figure 1 As shown, a gas instant water heater with automatic drainage and antifreeze includes a casing 1, a water inlet pipe 2 and a hot water outlet pipe 3, and also includes a normally open water supply valve 4, a normally closed drain valve 5, a temperature sensor 6 and control device,

[0022] The water outlet of the water supply valve 4 is connected to the water inlet of the water inlet pipe 2, and the water inlet of the water supply valve 4 is connected to the water source;

[0023] The drain valve 5 is communicated with the water outlet of the water supply valve 4, and the drain port of the drain valve 5 is provided with a drain port; the temperature sensor 6 is arranged in the shell 1; the water supply valve 4, a drain valve 5 and the temperature sensor 6 are connected to the Control unit connection.

[0024] The water supply valve 4 is a normally open switch valve for water, and the drain valve 5 is a normally closed switch valve for water.

[0025] ...

Embodiment 2

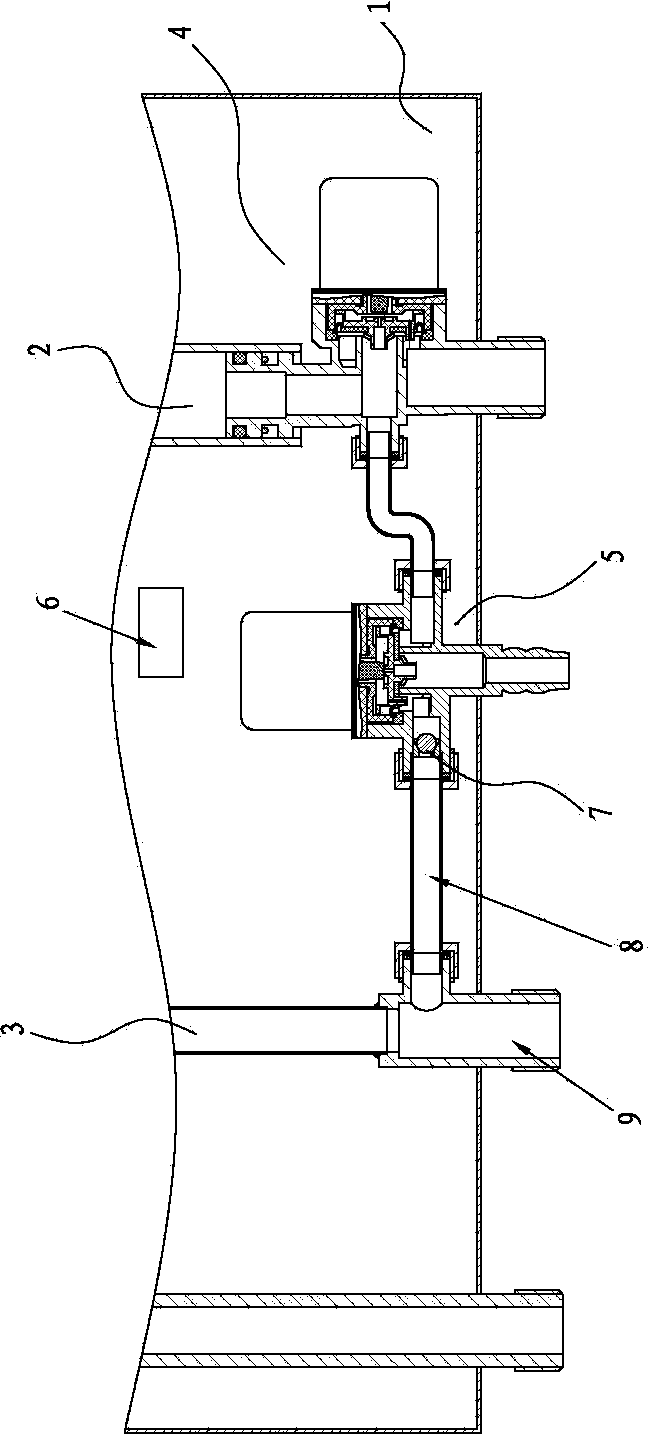

[0032] Such as figure 2 As shown, a one-way valve 7 and a water guide pipe 8 are also included, and the one-way valve 7 is arranged at the water outlet end of the water guide pipe 8;

[0033] The water inlet end of the water guide pipe 8 communicates with the water outlet interface 9 on the hot water outlet pipe 3 , and the water outlet end of the water guide pipe 8 communicates with the water inlet end of the normally closed water switch valve 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com