Optical fiber composite aerial insulated cable

An aerial insulated cable and optical fiber composite technology, which is applied in the direction of communication cables, power cables, and power cables with shielding layers/conductive layers, etc., can solve the problems of increased construction volume and construction period, low strength of communication optical cables, and high construction costs. Achieve the effects of reducing construction workload, solving the problem of being easily damaged by external forces, and saving project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

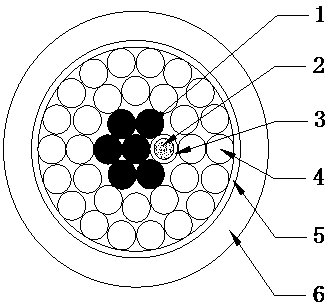

[0010] Such as figure 1 As shown, an optical fiber composite overhead insulated cable according to the present invention includes an assembly located in the center of the cable, the assembly is formed by twisting a plurality of steel wires 1 and optical units, and the conductive monofilament is twisted outside the assembly 4 to form a conductive layer, which is covered with a semi-conductive shielding layer 5 and an insulating layer 6 in sequence;

[0011] The cable paste is filled between the optical fiber 2 and the steel loose tube 3, and the excess length of the optical fiber 2 is controlled between 4‰ and 6‰.

[0012] The present invention provides an optical fiber composite aerial insulated cable. The above description is only a preferred implementation method of the present invention. Several improvements are made, and these improvements should also be regarded as the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com