Spliced conductor type cable

A cable and body type technology, which is applied in the field of splicing conductor type cables, can solve problems such as insufficient compression, large use area, and occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

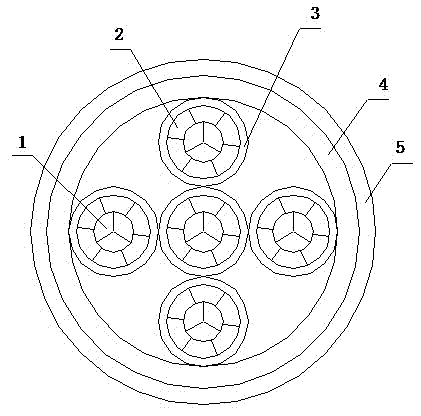

[0013] Such as figure 1 As shown, Fig. 1 is a cross-sectional view of a spliced conductor type cable in an embodiment of the present invention.

[0014] refer to figure 1 , the embodiment of the present invention provides a spliced conductor type cable, including: a plurality of conductors, the wires are covered with an inner insulating layer 3, twisted around a center, and the entire outer surface is covered with inner steel wire armor in turn 4 and outer insulating layer 5. Among them, the conductor is formed by twisting the inner conductor 1 and the outer conductor 2, the inner conductor 1 has a circular cross-section, and is composed of a plurality of core wires with a semicircular or fan-shaped cross-section, and the outer conductor 2 has a circular cross-section, and The inner conductor 1 is spliced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com