Patents

Literature

30results about How to "Increase the degree of compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

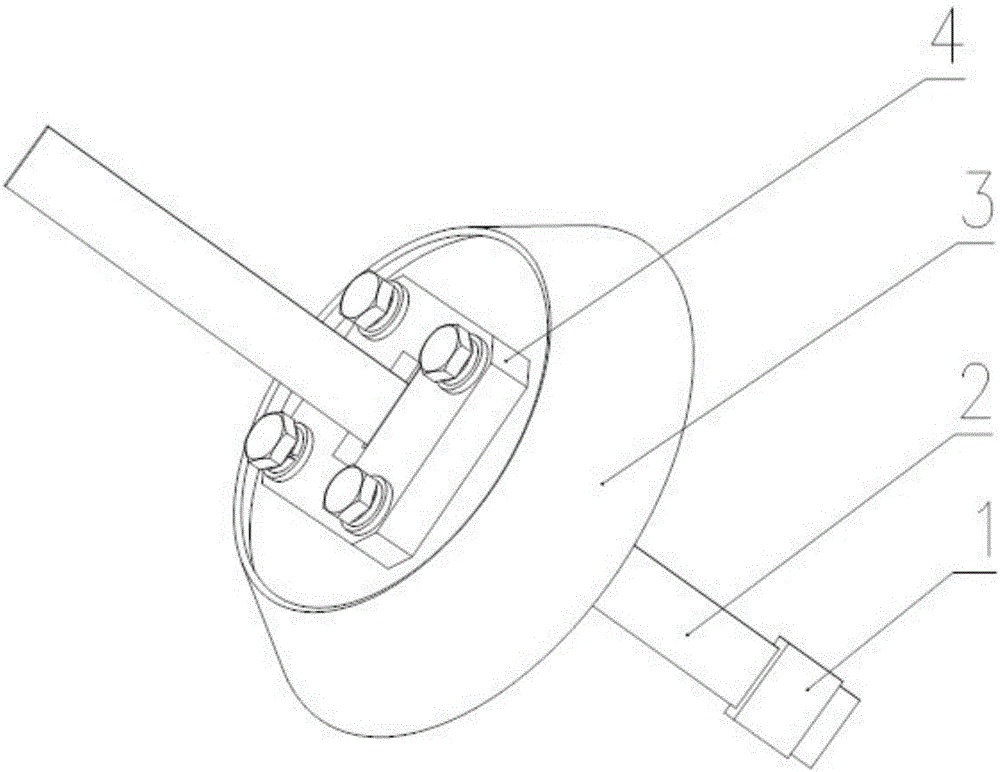

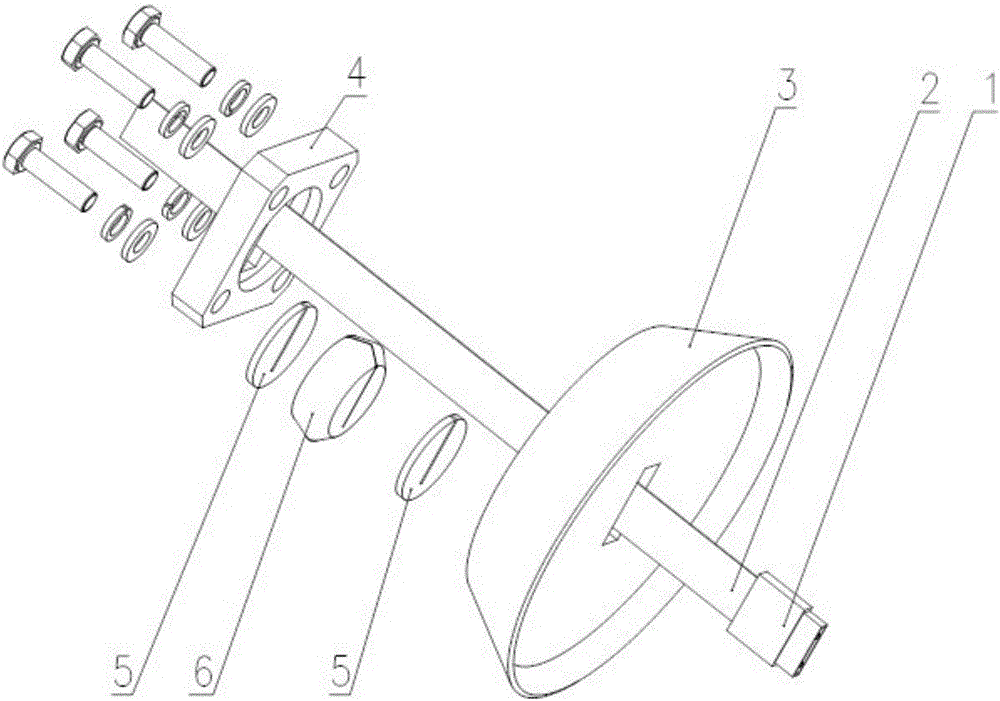

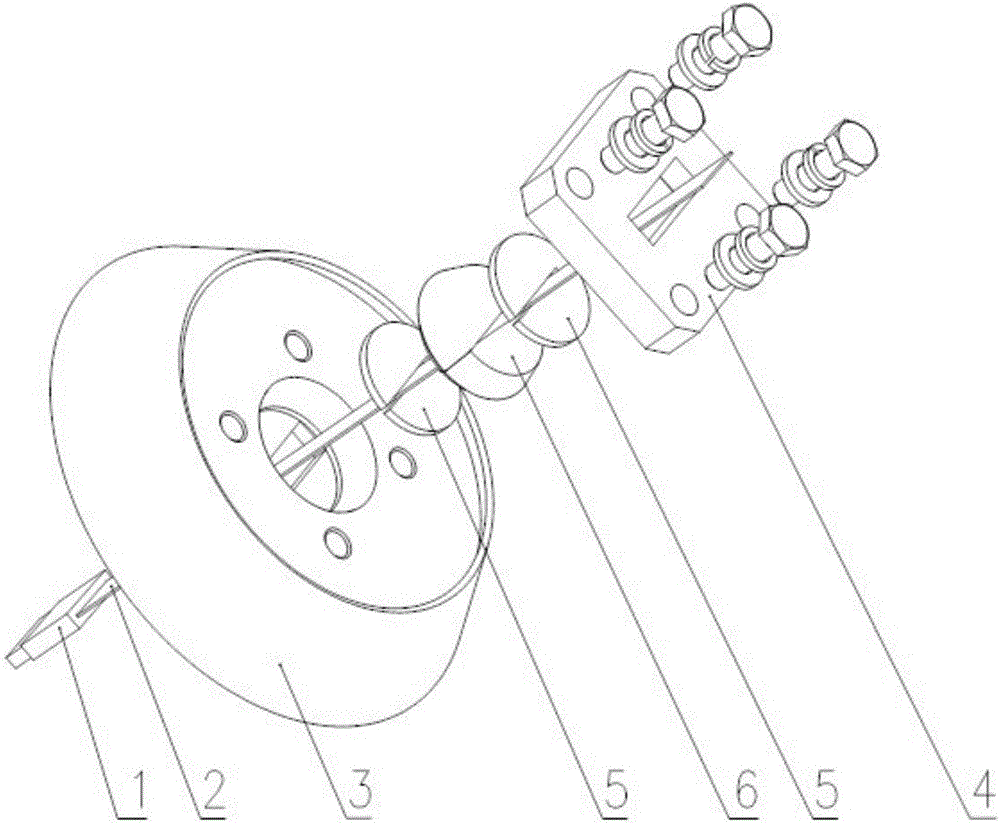

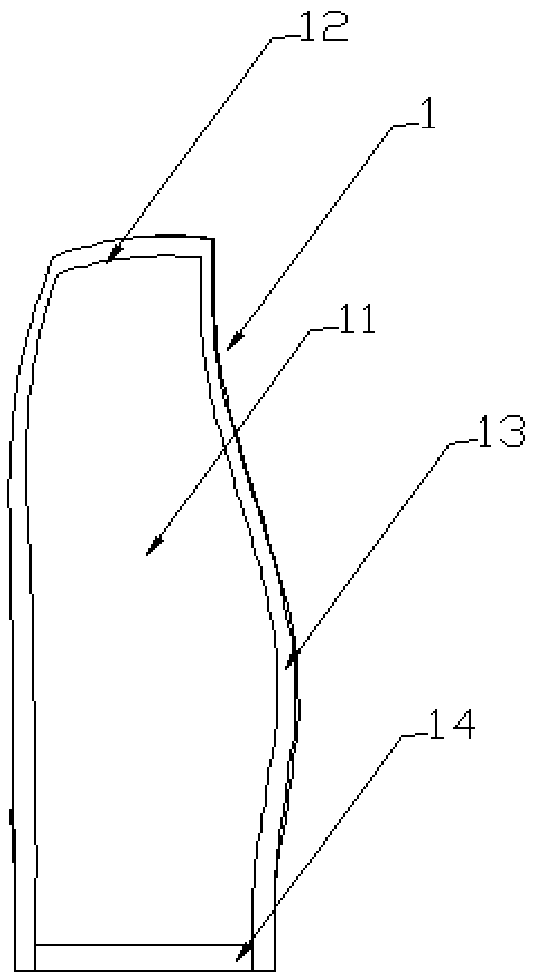

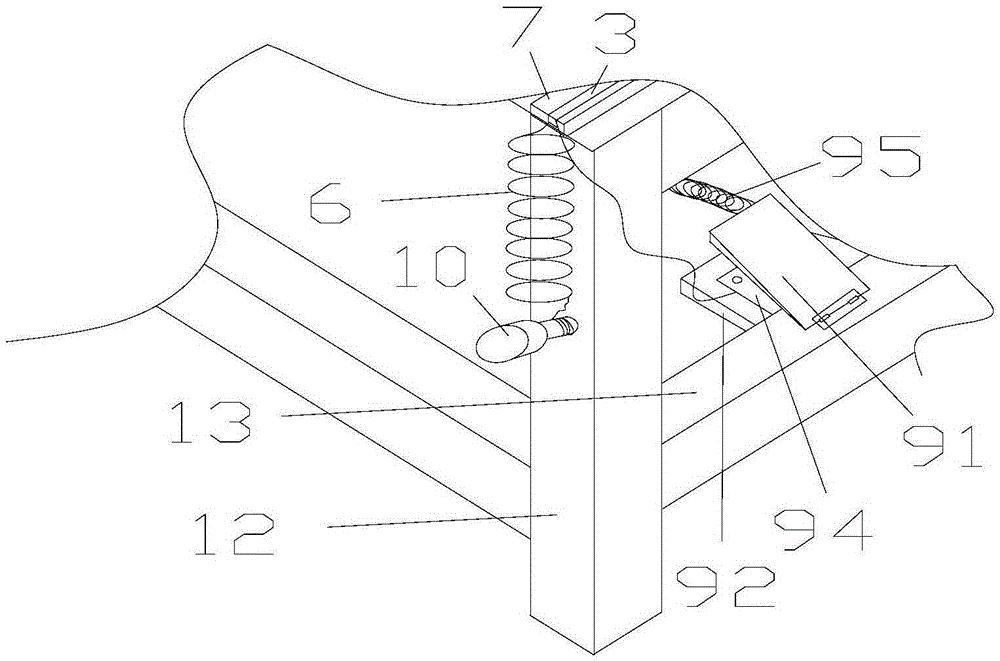

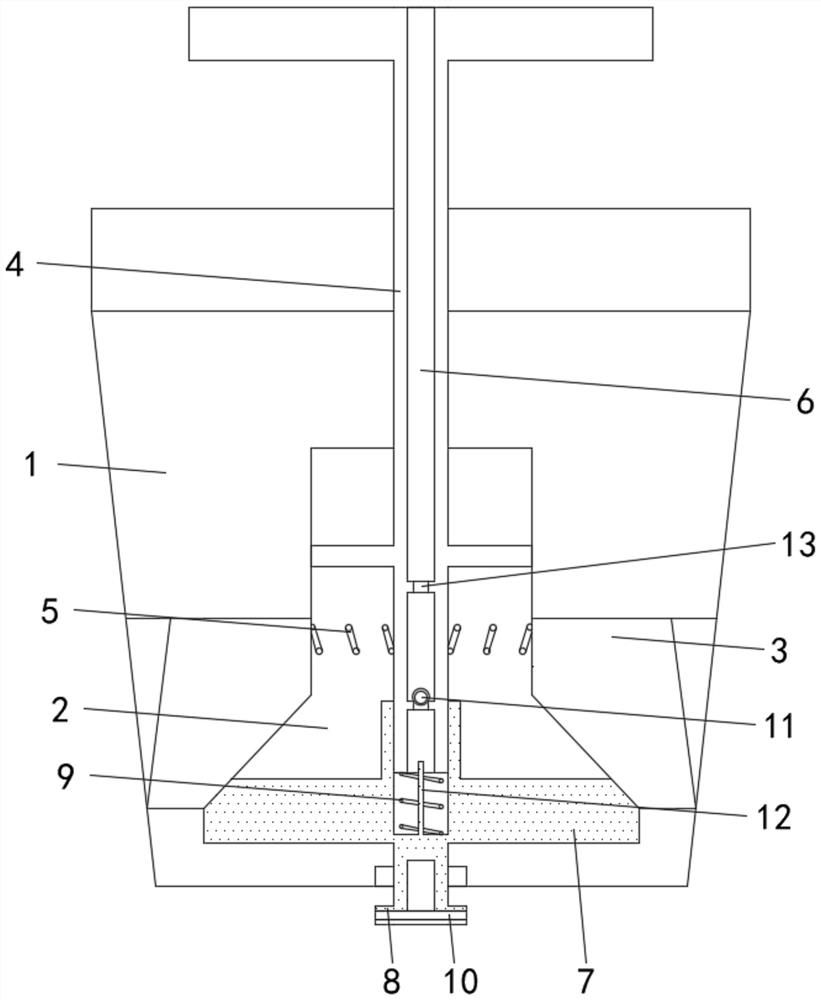

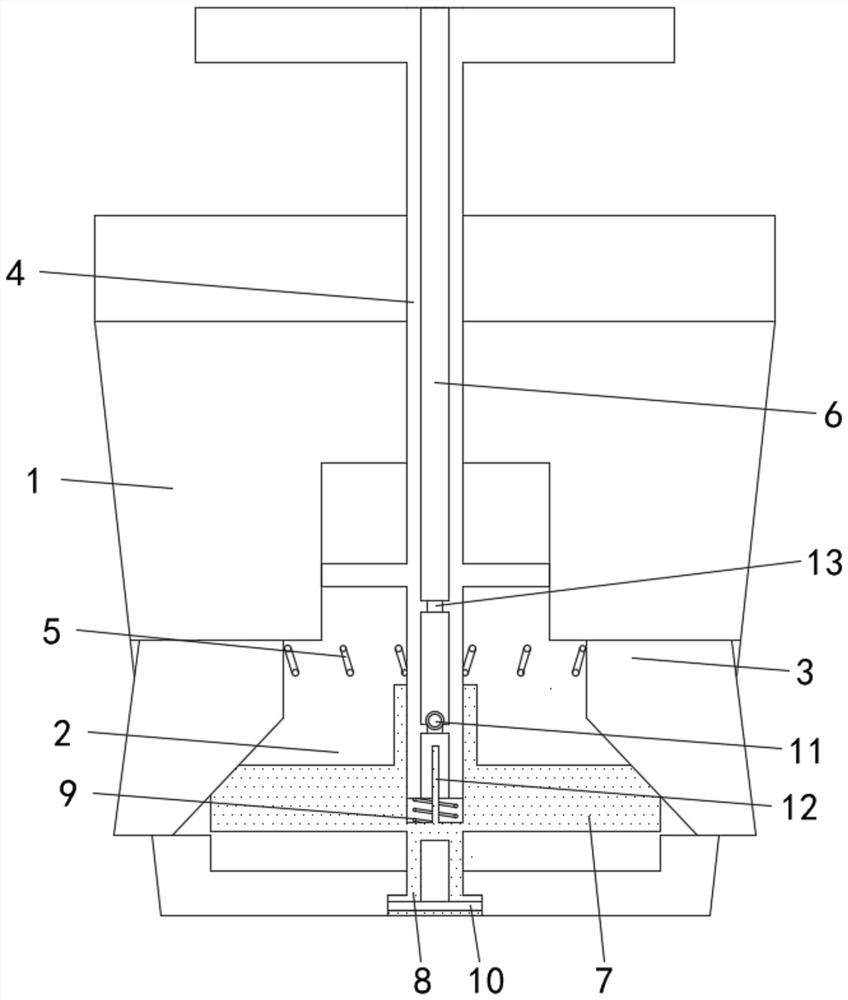

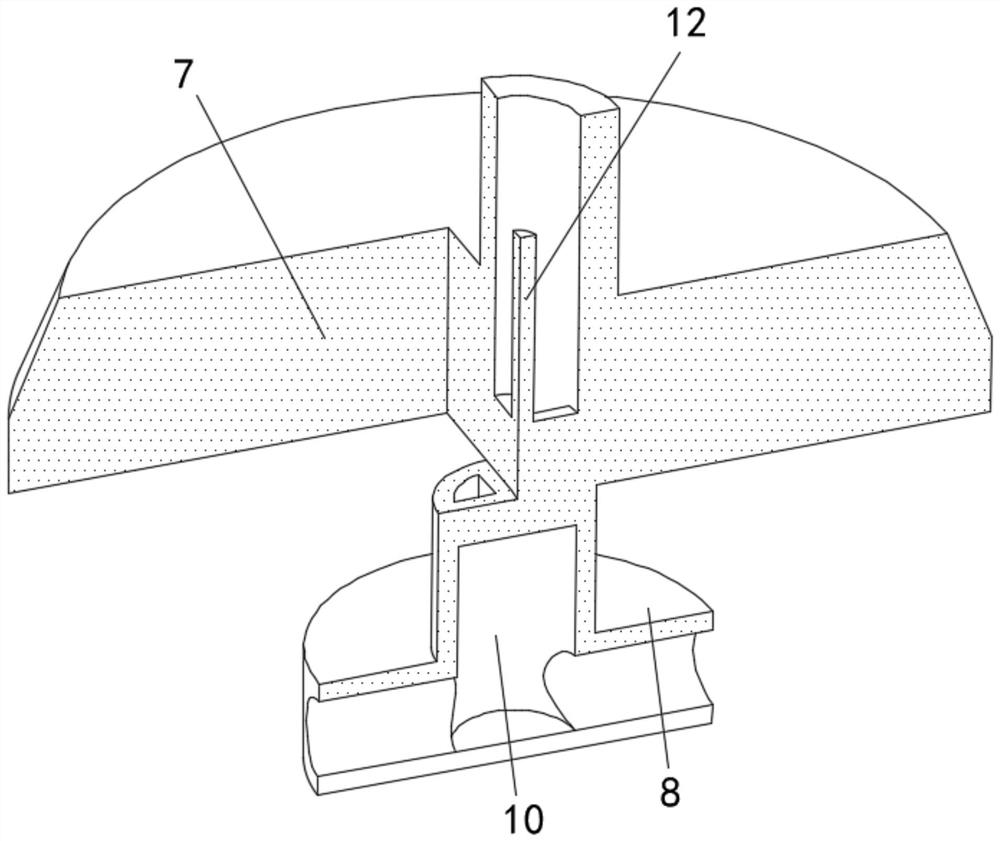

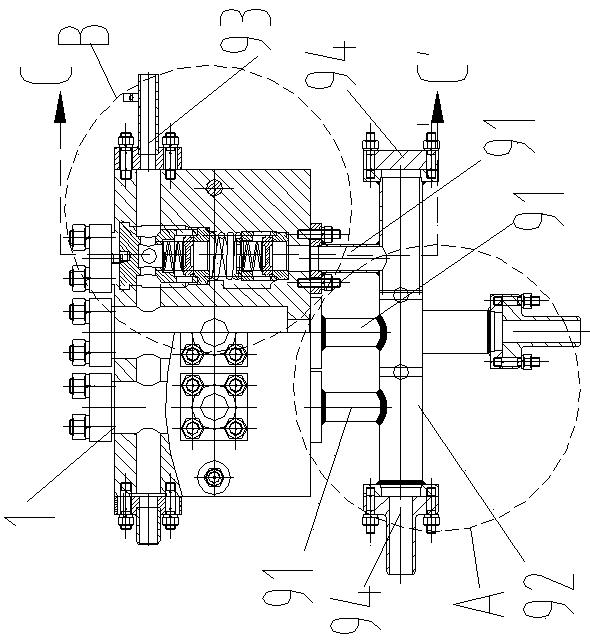

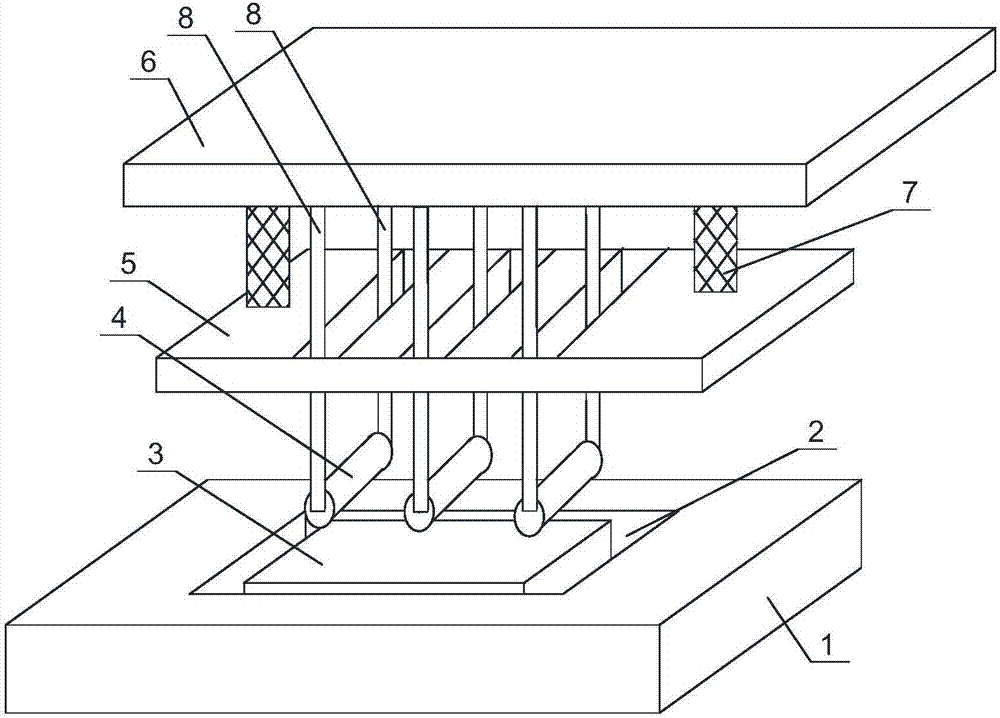

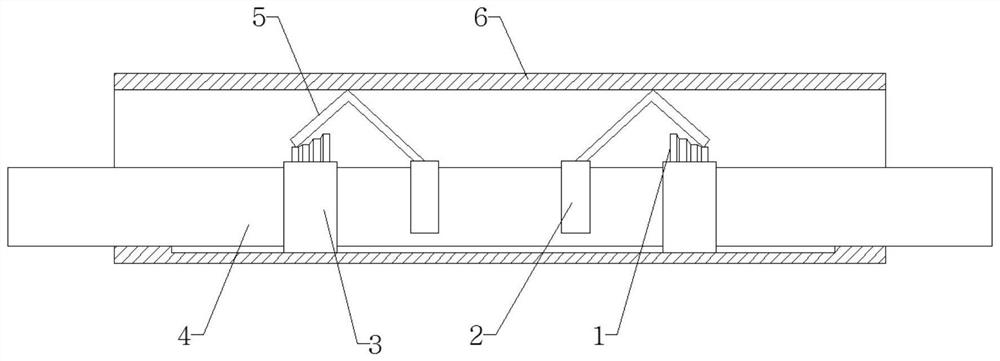

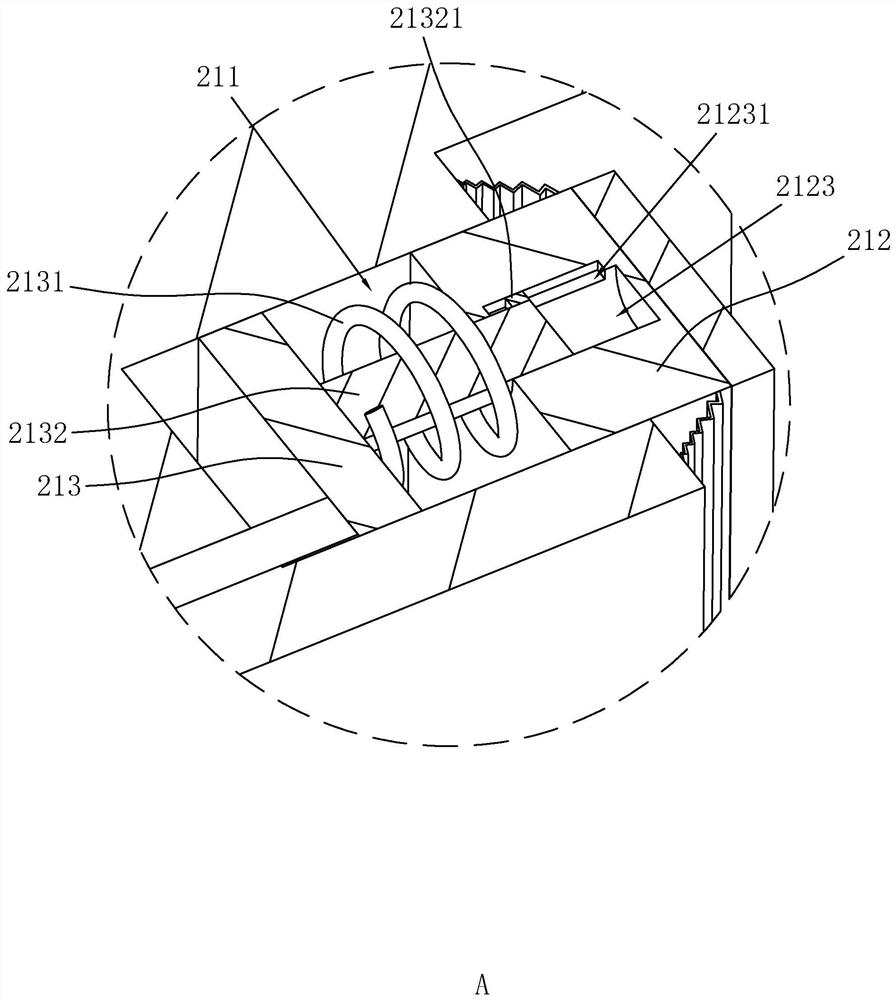

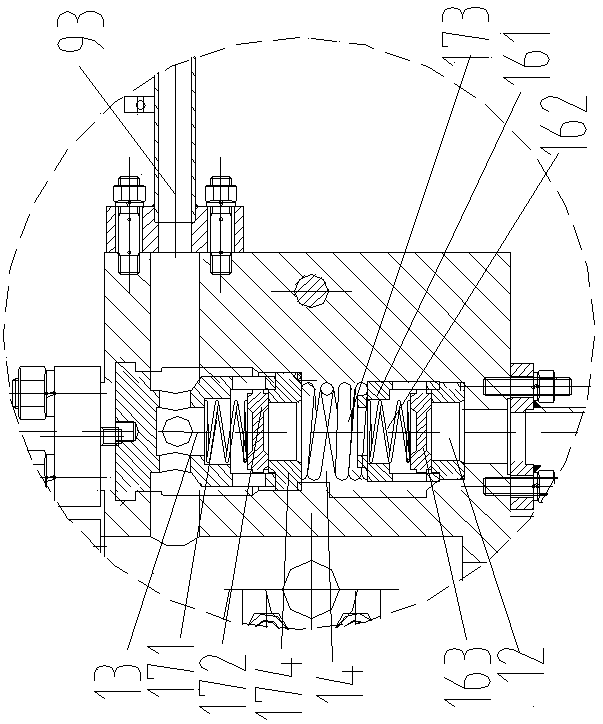

Flat cable penetration sealing device with high sealing property in dynamic environment

ActiveCN106439240AMeet the penetration sealIncrease the degree of compressionPipesCable inlet sealing meansMechanical engineeringEngineering

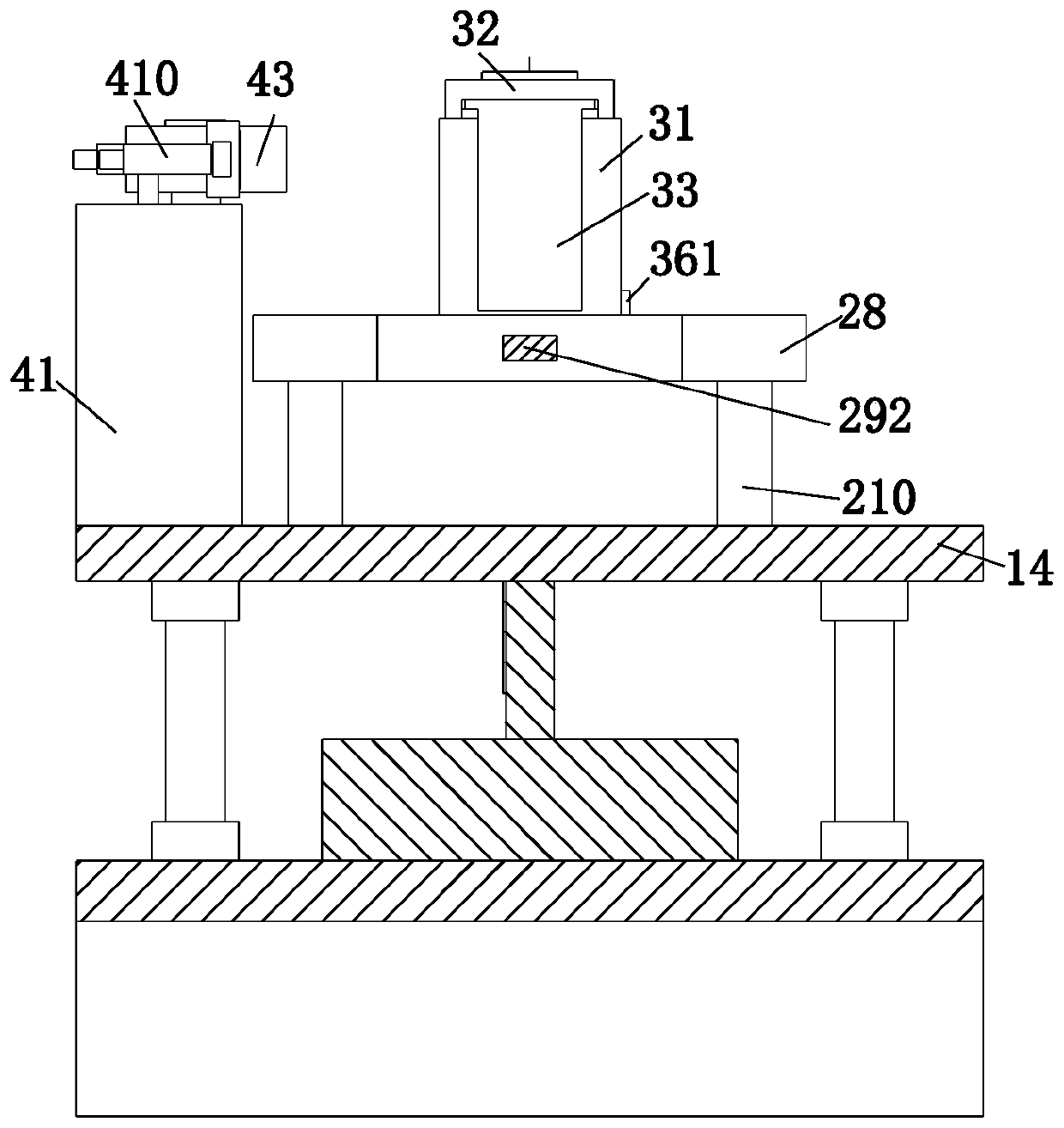

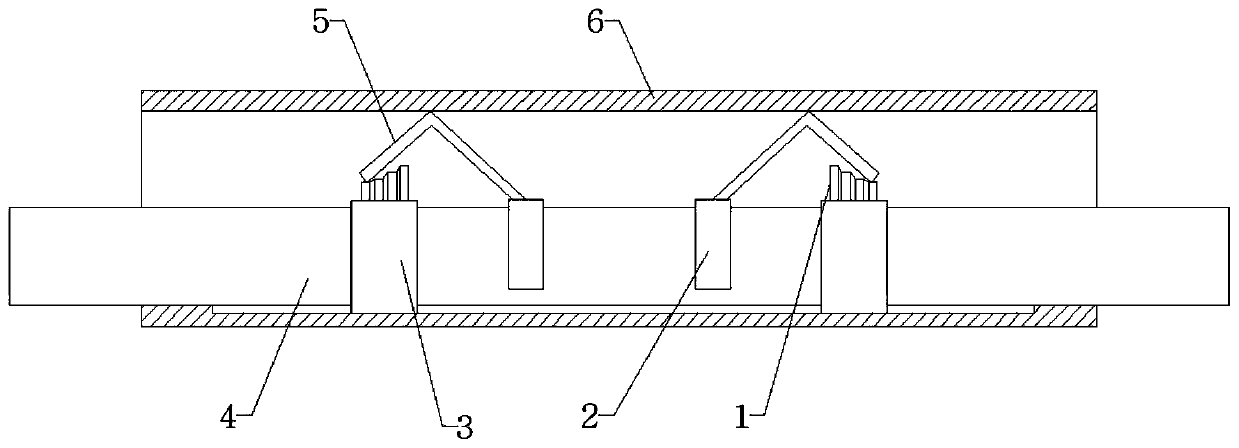

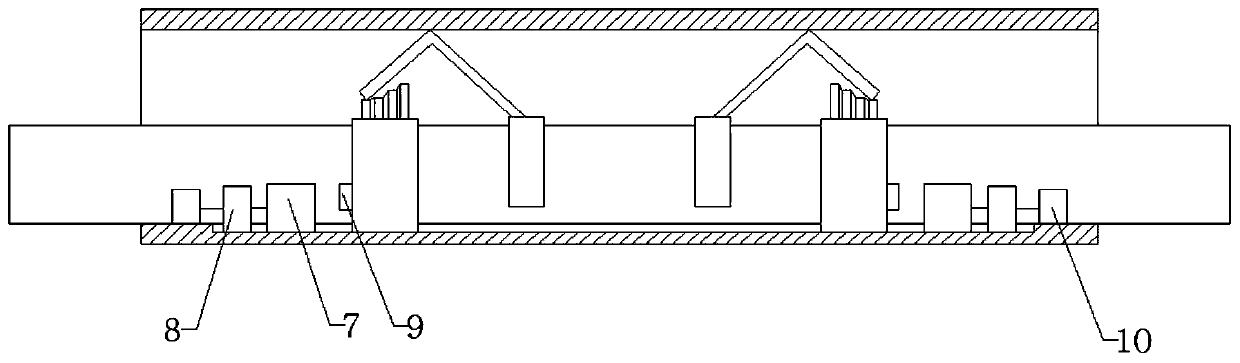

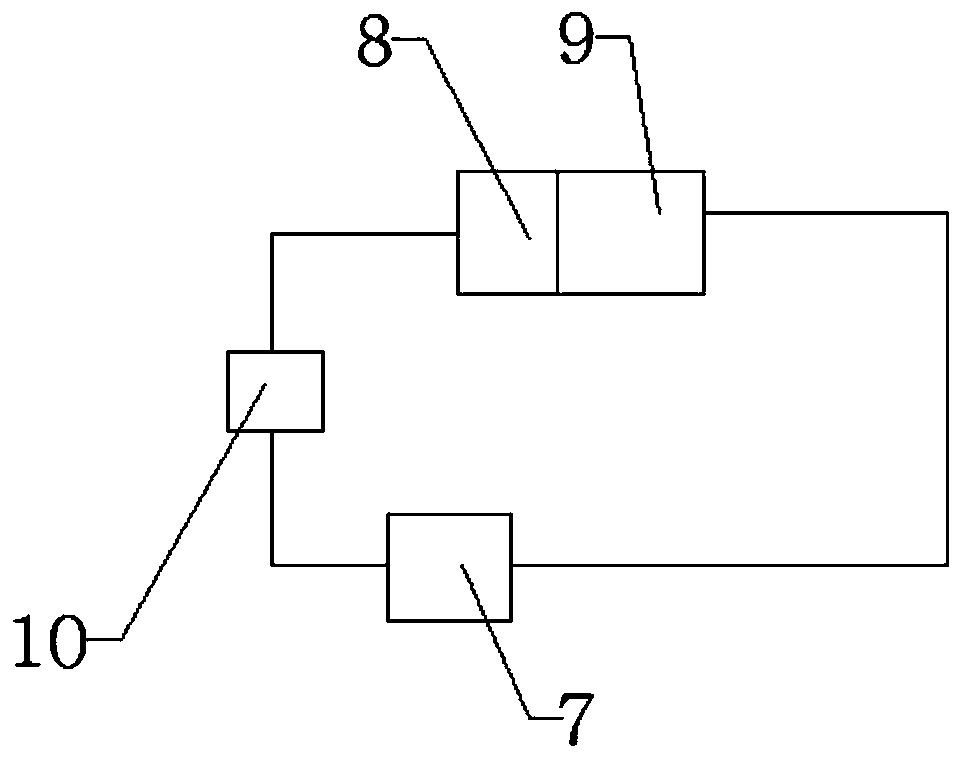

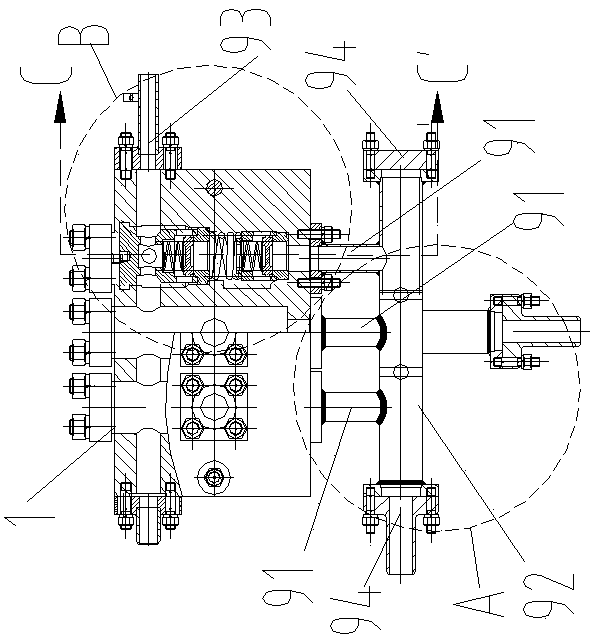

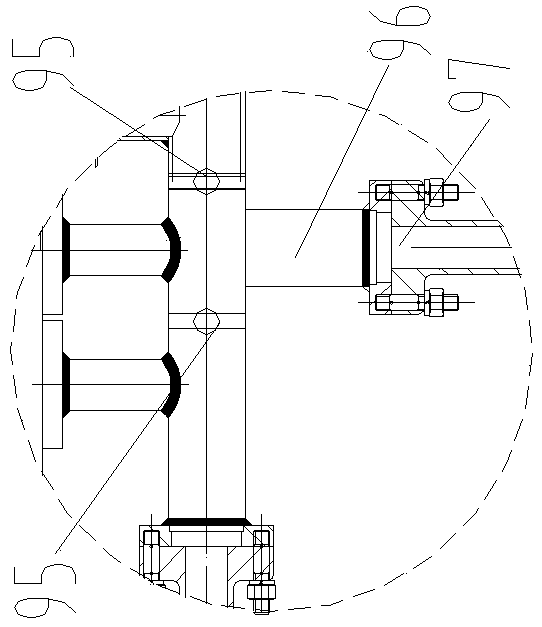

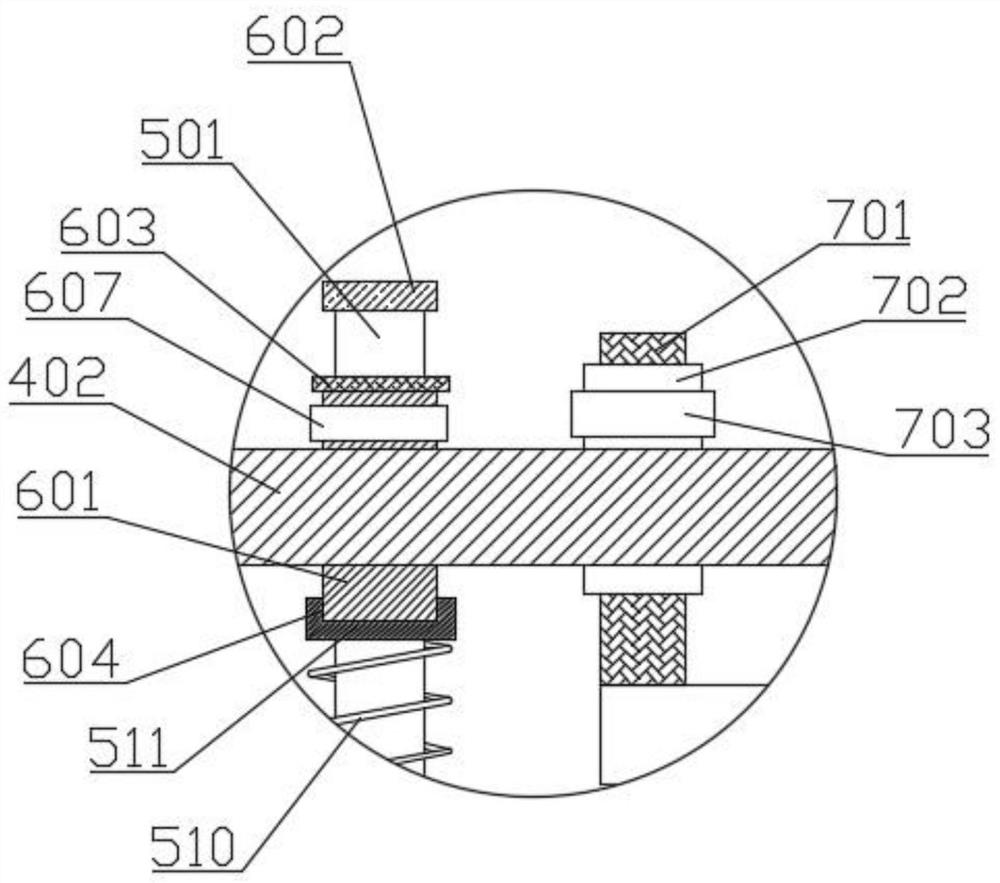

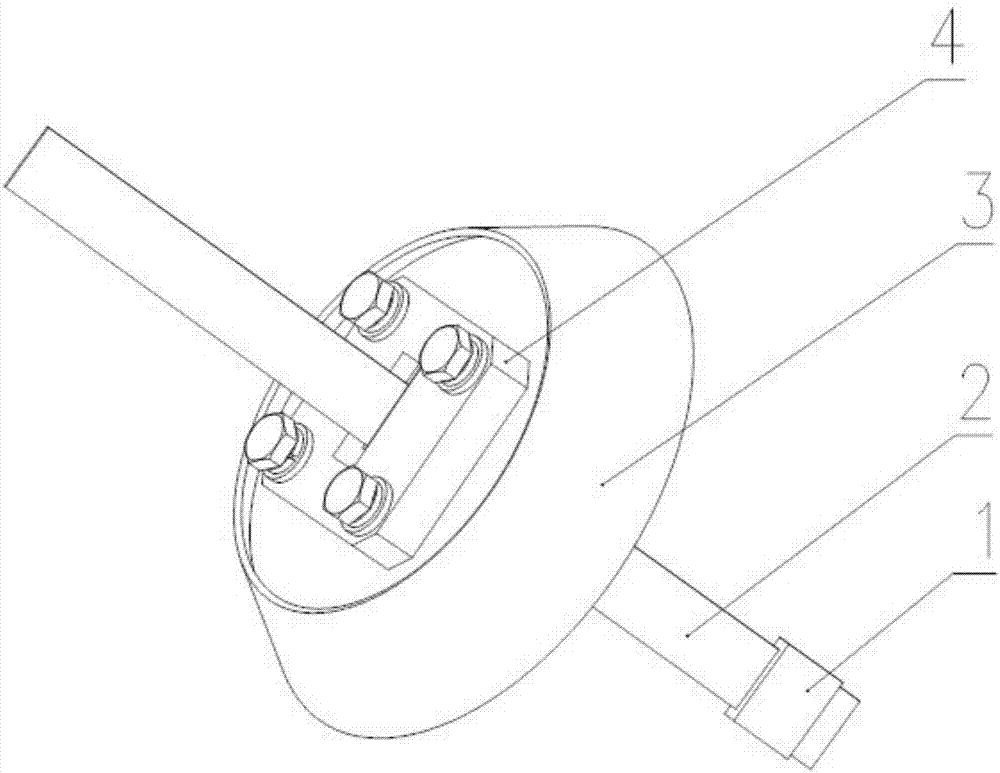

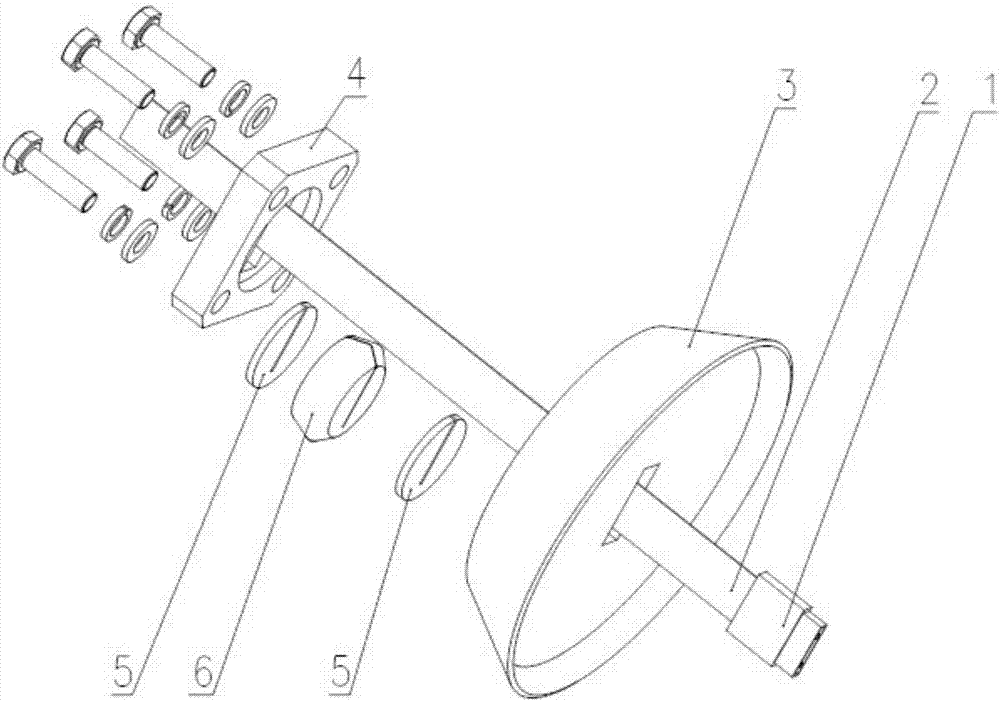

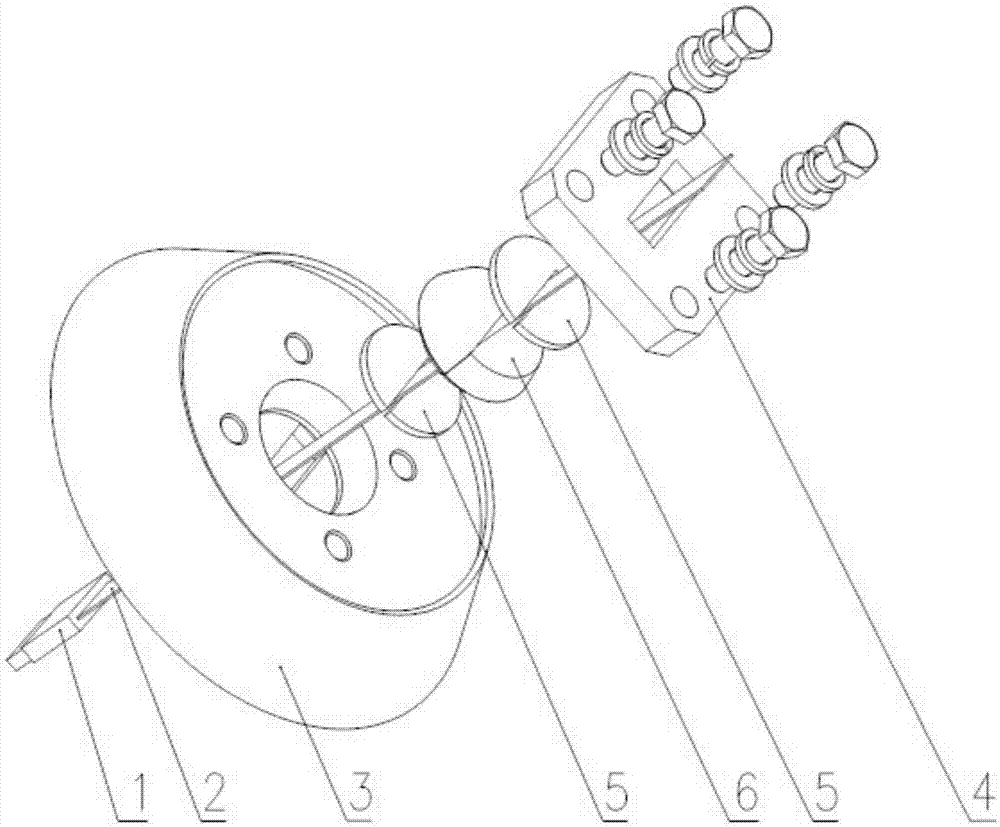

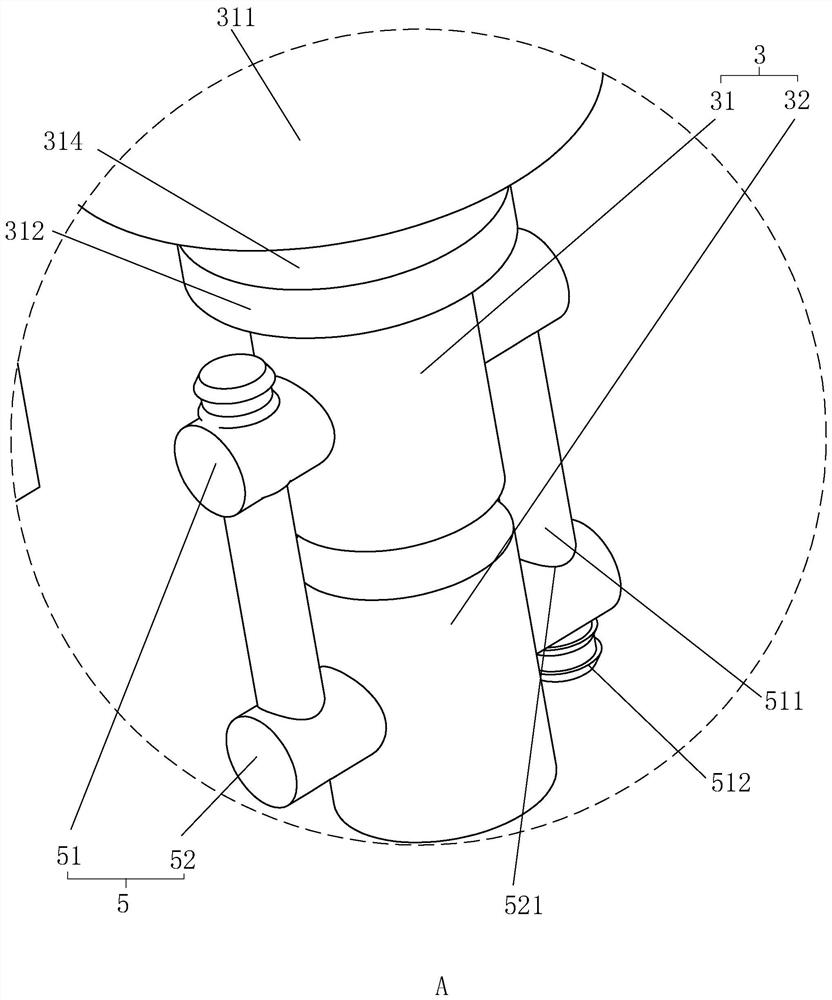

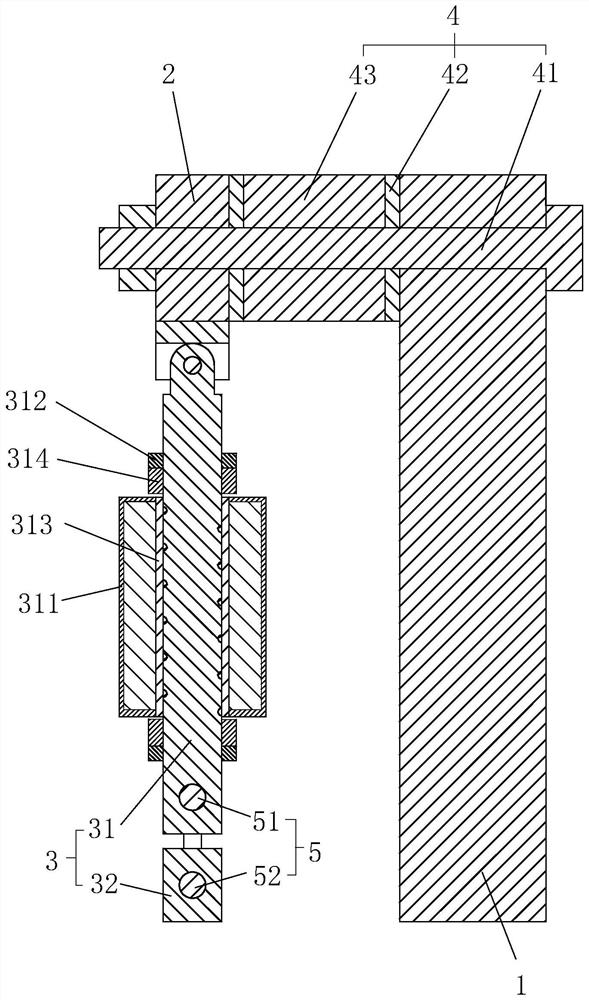

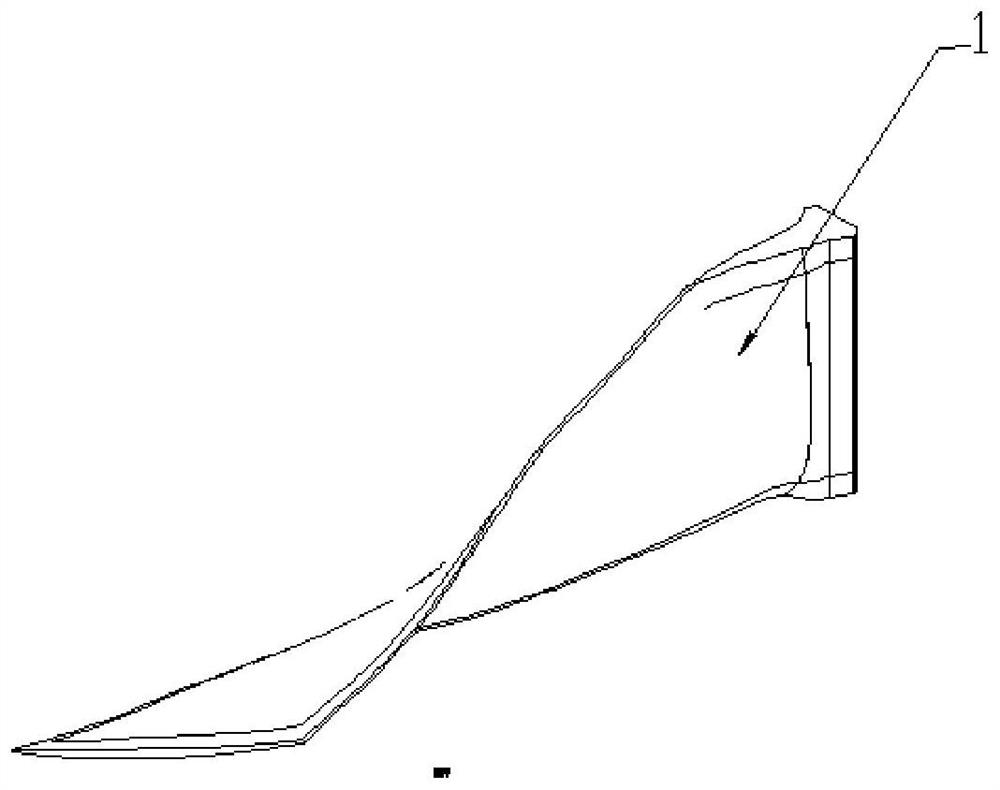

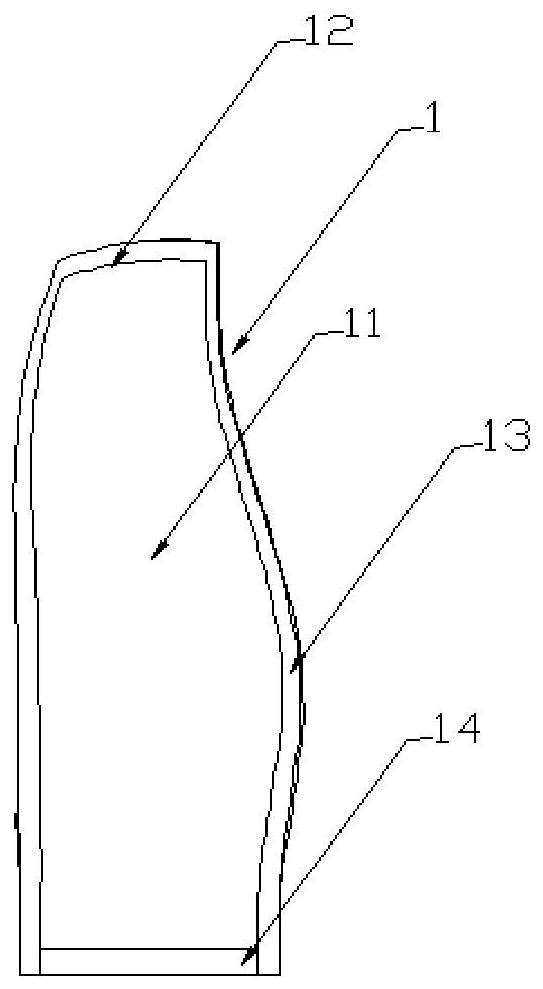

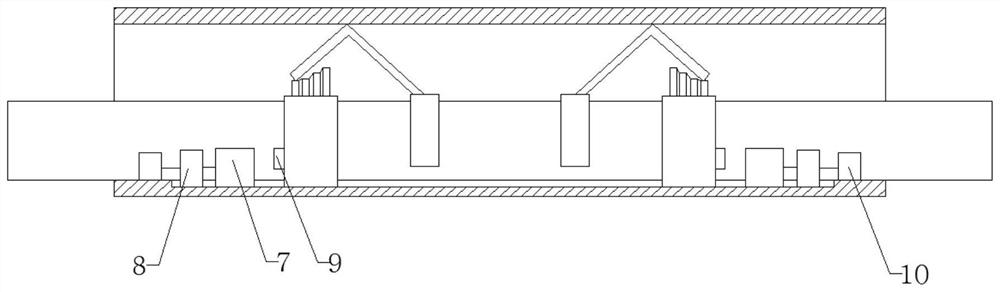

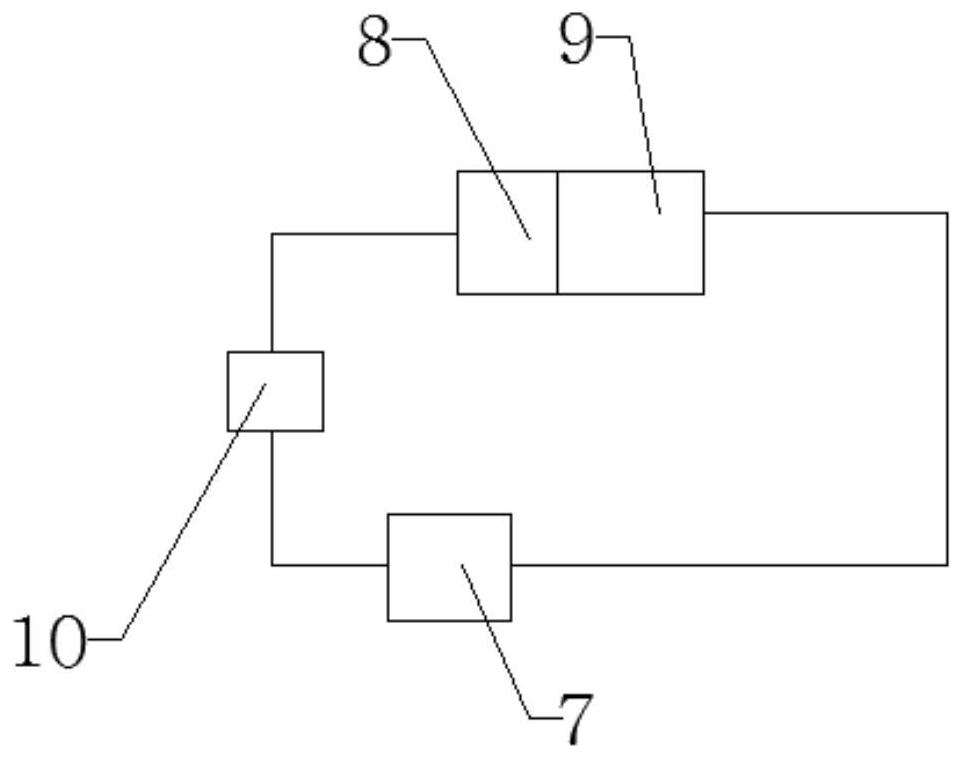

The invention discloses a flat cable penetration sealing device with high sealing property in a dynamic environment. According to the device, a flat cable is embedded into a gap of an elastic sealing block, the elastic sealing block is put into a circular hole of a sealing cabin cover, two cushion blocks are respectively mounted on two small end faces of the elastic sealing block, a sealing gland and the sealing cabin cover are in fastened connection by screwing the bolts, the elastic sealing block is axially extruded by the sealing gland so as to gradually deform outwards, so that cone seal is formed between the sealing gland and a circular truncated cone-shaped hole of the sealing cabin cover, plane seal is formed between the elastic sealing block and the flat cable, and internal and external dual seal functions are realized. The section diameter of the circular truncated cone-shaped hole of the sealing cabin cover is gradually reduced, the compression degree of the elastic sealing block is gradually increased, and high sealing property can be achieved, so that the sealing property with the same order as that of the cone seal is achieved, and flat cable penetration seal with high sealing property in the dynamic environment is met.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

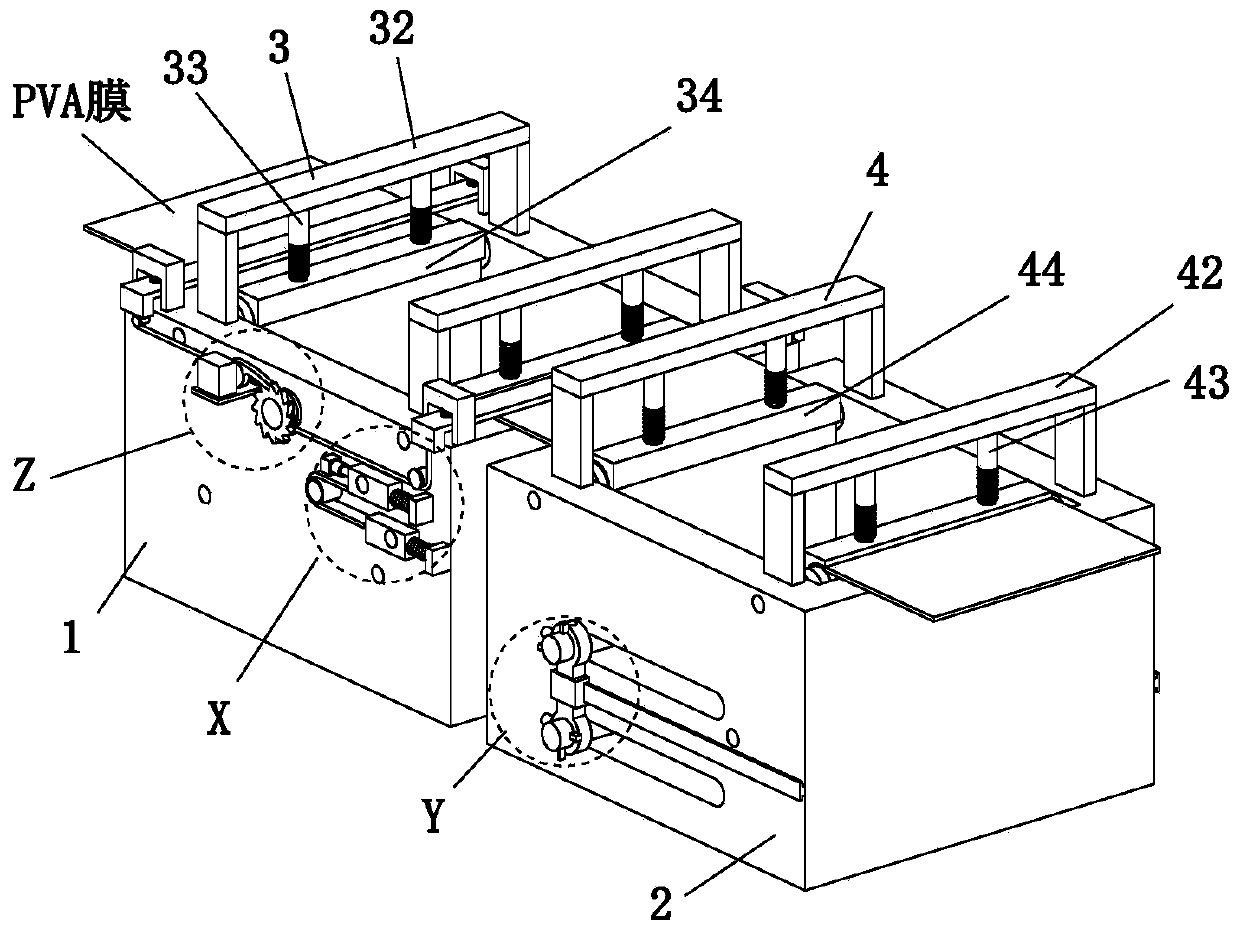

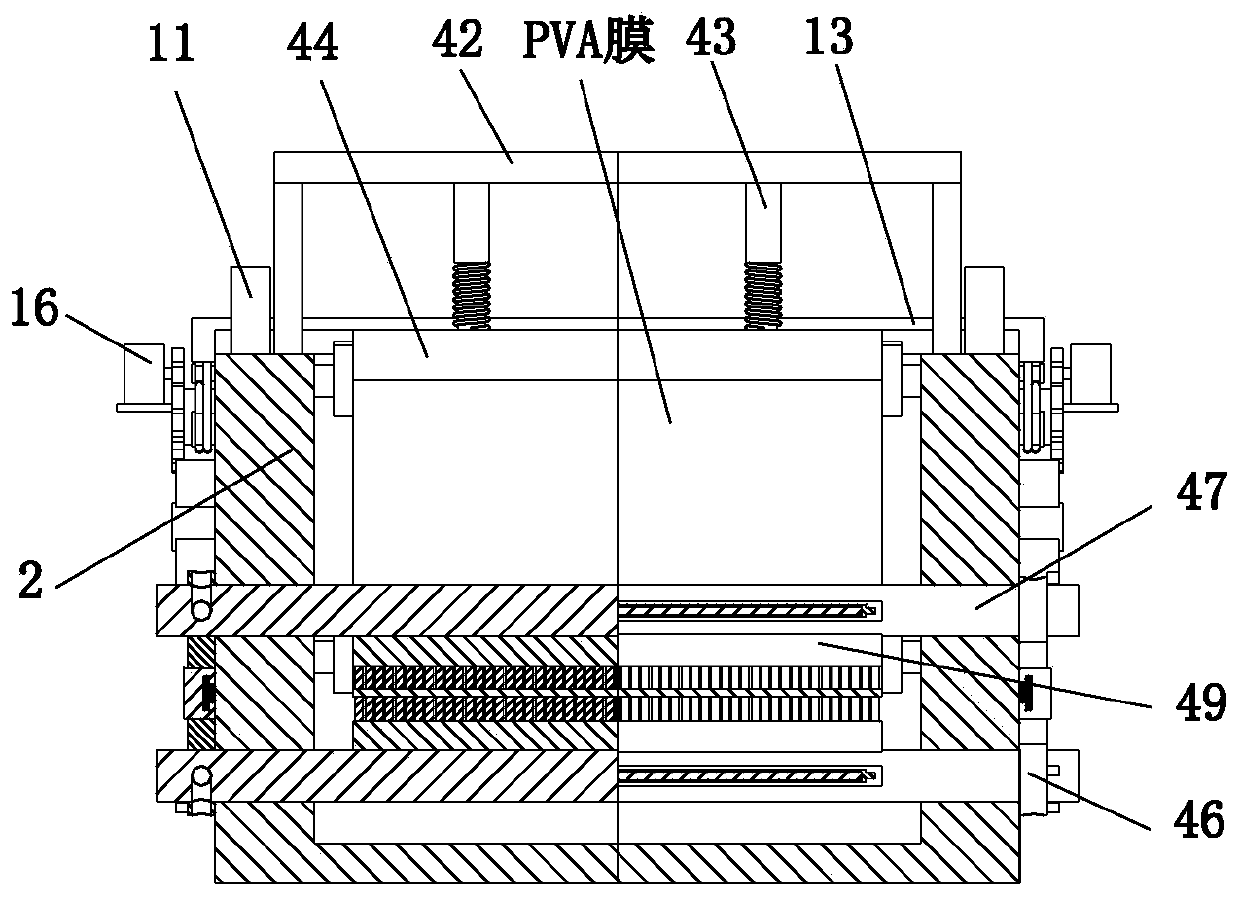

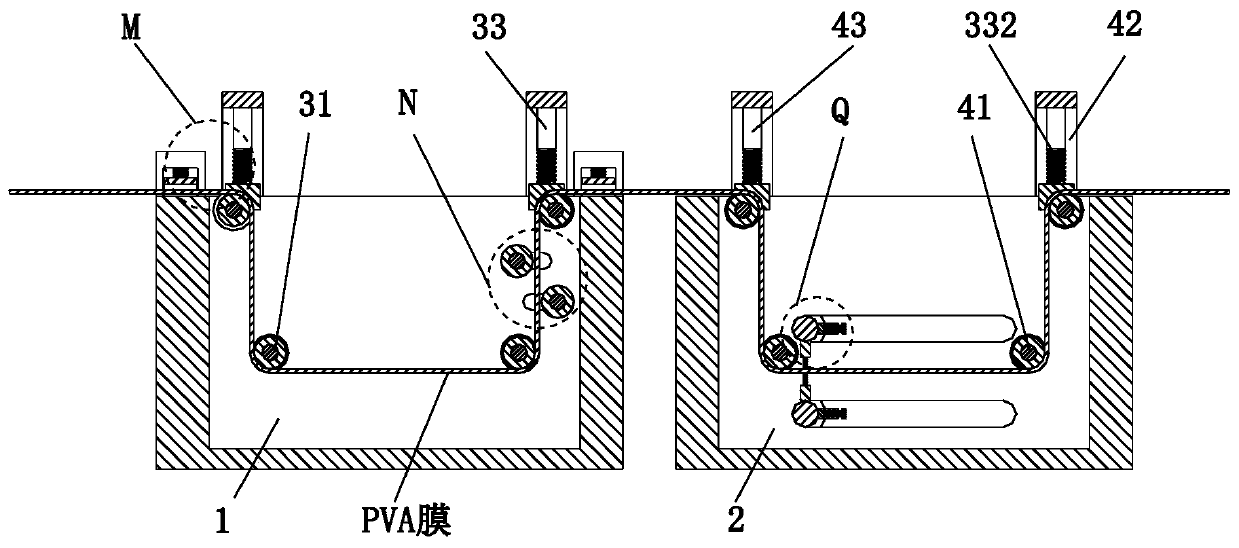

Liquid crystal display polarizer production stretching procedure processing technology

InactiveCN111113870AReduce work intensityImprove work efficiencyLiquid surface applicatorsFlat articlesLiquid-crystal displayPhysical chemistry

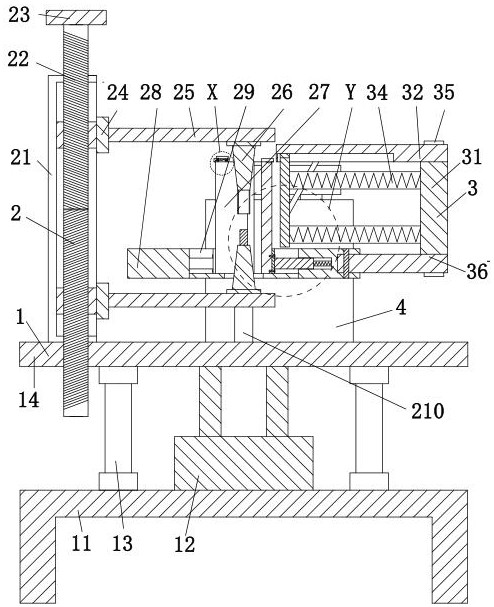

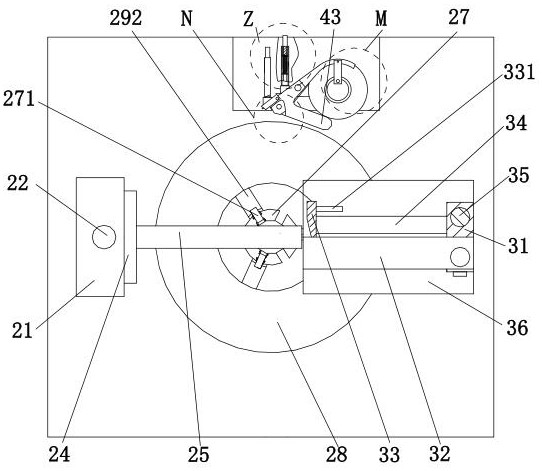

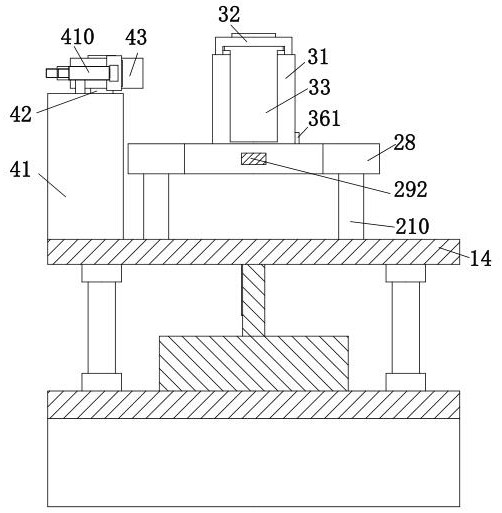

The invention relates to a liquid crystal display polarizer production stretching procedure processing technology. The technology uses a liquid crystal display polarizer production stretching procedure processing device, wherein the liquid crystal display polarizer production stretching procedure processing device comprises a stretching groove, a color supplementing groove, a stretching device anda color supplementing device, wherein the stretching groove is located on the left side of the color supplementing groove, the stretching device is installed on the stretching groove, and the color supplementing device is mounted on the color supplementing groove. According to the liquid crystal display polarizer production stretching procedure processing technology, PVA film stretching and colorsupplementing treatment are carried out by adopting the design concept of intermittent joint operation, the intermittent working pace of the stretching device and the intermittent working pace of thecolor supplementing device are consistent and controlled mechanically, the working intensity of workers is relieved, and the working efficiency is improved.

Owner:丁晟

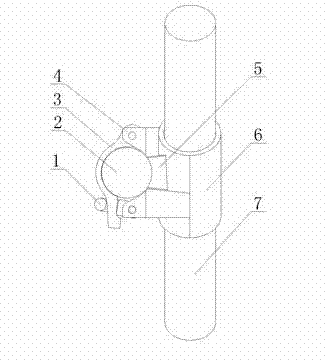

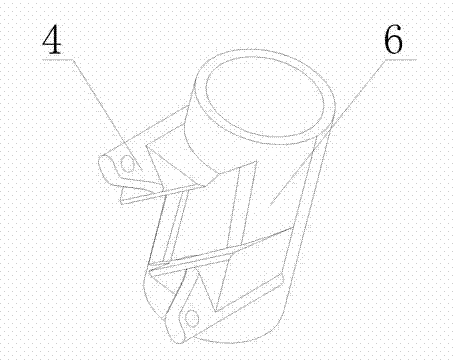

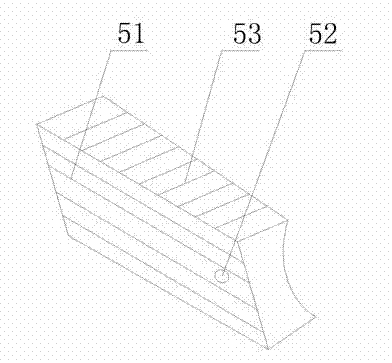

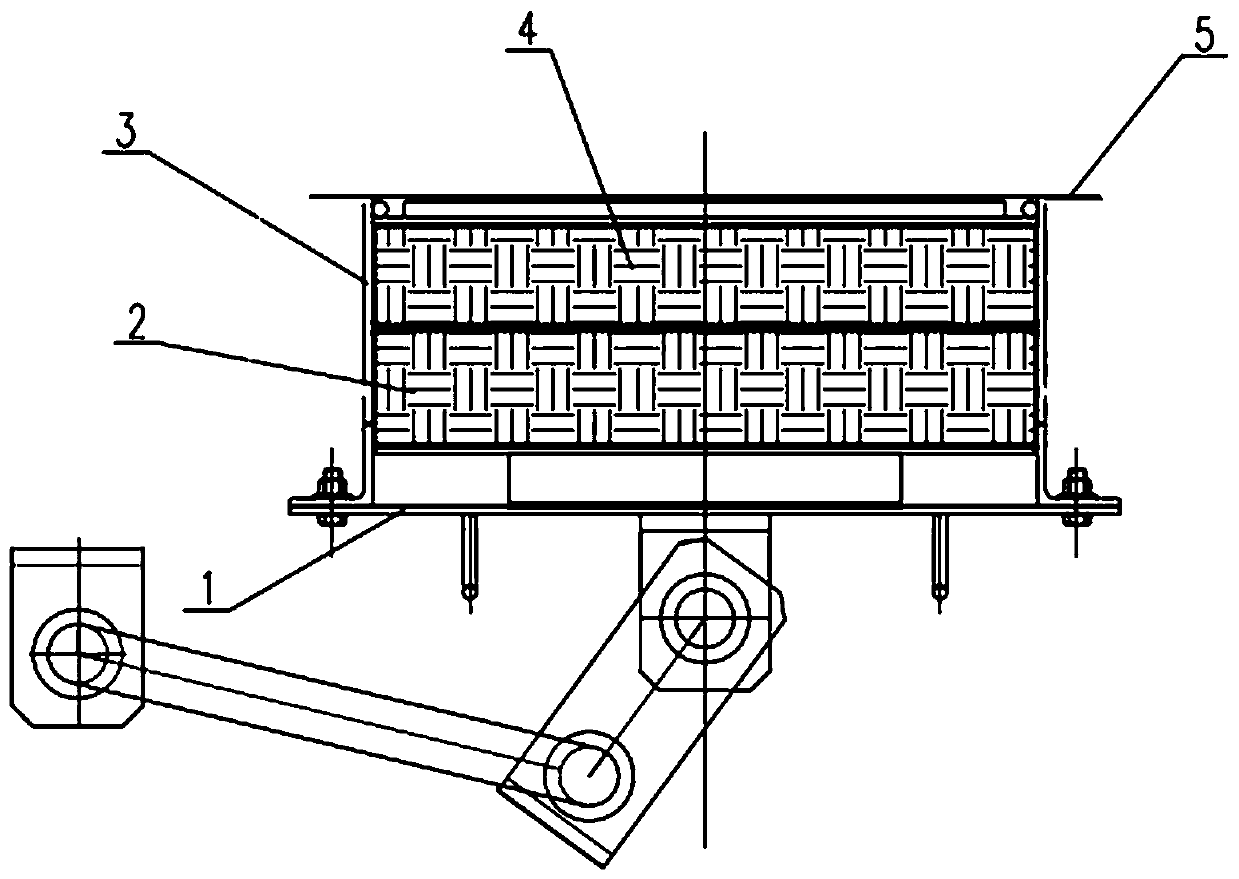

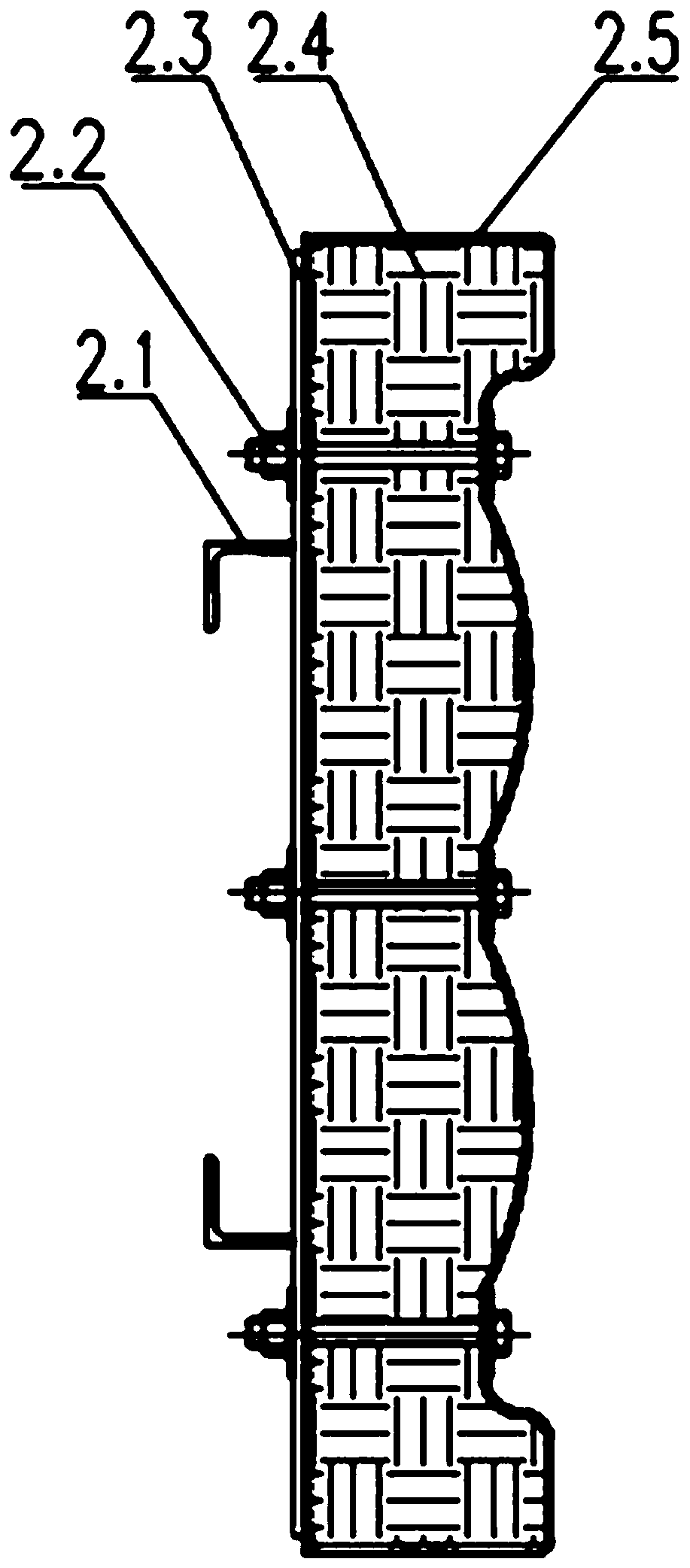

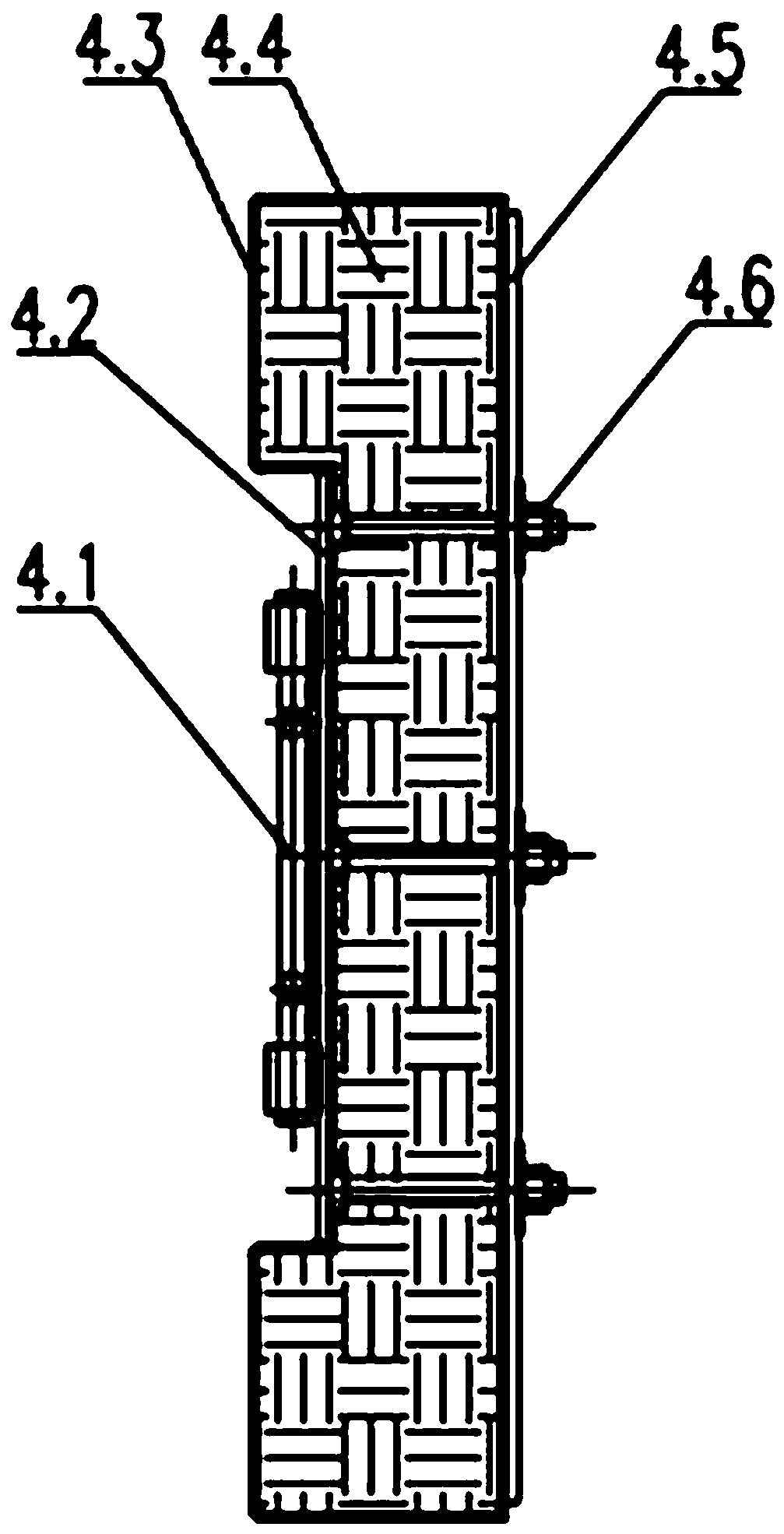

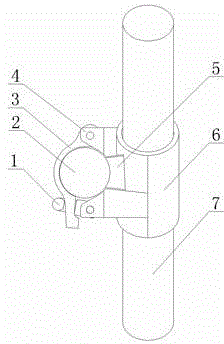

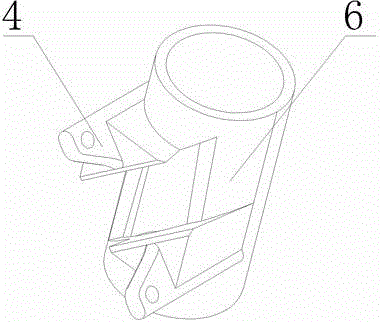

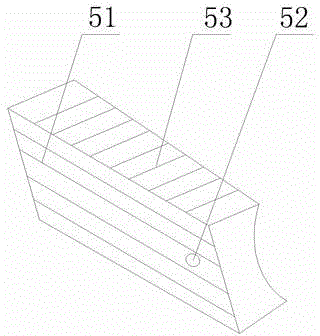

Inclined strut buckle and sliding sleeve thereof for steel pipe scaffold

InactiveCN103089000ANot easy to dropPrevent slidingScaffold connectionsMechanical engineeringSteel tube

The invention discloses an inclined strut buckle and a sliding sleeve thereof for a steel pipe scaffold. The buckle comprises the sliding sleeve for sleeving on a fixed steel pipe in a sliding mode and a boss which is arranged on one side of the outer circumference face of the sliding sleeve in a protruded mode. A face of the boss is provided with an arc positioning supporting groove for positioning an inclined strut steel pipe. The axis of the positioning supporting groove is crossed with an axial space of the sliding sleeve with an included angle ranging from 30 degrees to 60 degrees. The sum of the radius of an inner hole of the sliding grove and the radius of the positioning supporting groove is smaller than the distance between axes of the positioning supporting groove and the sliding sleeve. A connection groove is arranged in the bottom face of the positioning supporting groove, wherein an extension direction of the connection groove is identical with an extension direction of the positioning supporting groove and the connection groove penetrates through the inner hole of the sliding sleeve. A press module for pressing the inclined strut steel pipe in the positioning supporting groove in an arranged mode is arranged on the face of the boss. As the sliding sleeve is sleeved on the fixed steel pipe, a buckle body just needs to be fixedly connected with the inclined strut buckle and installation and dismantling are convenient. Besides, the buckle body is not prone to fall off.

Owner:朱新伟

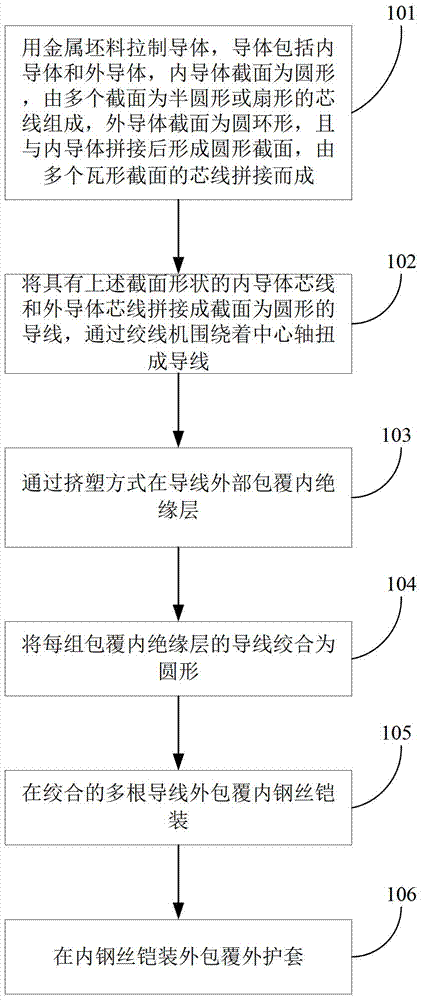

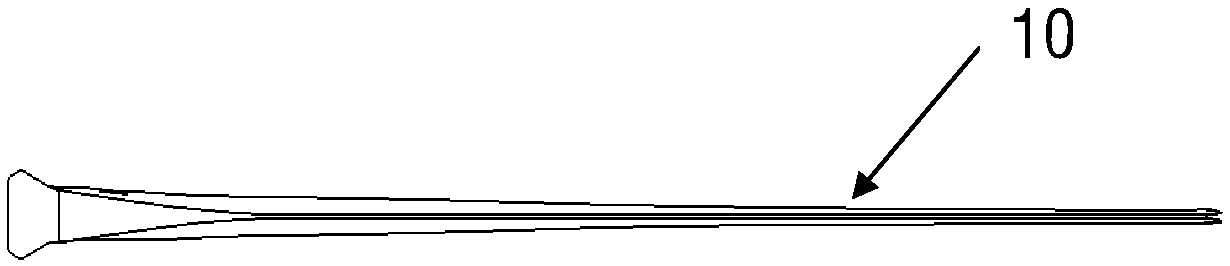

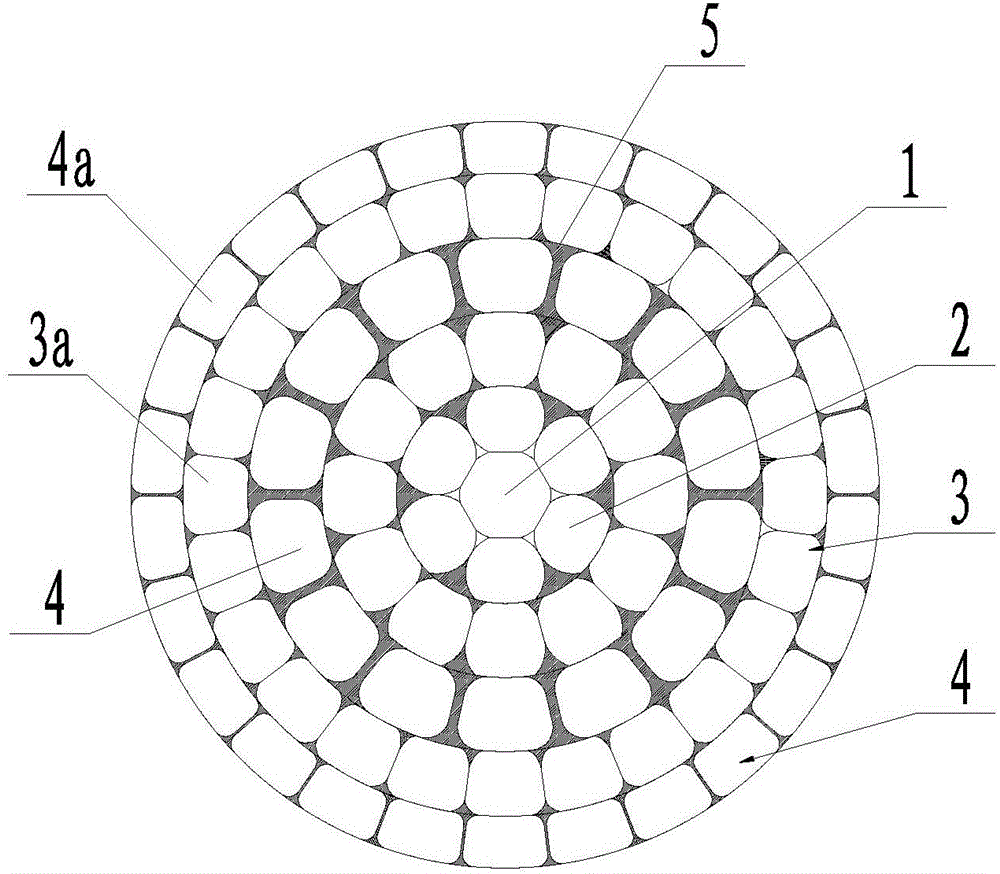

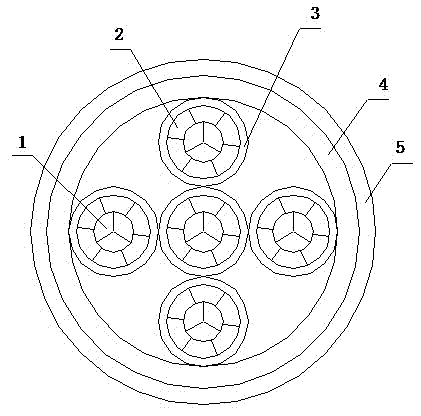

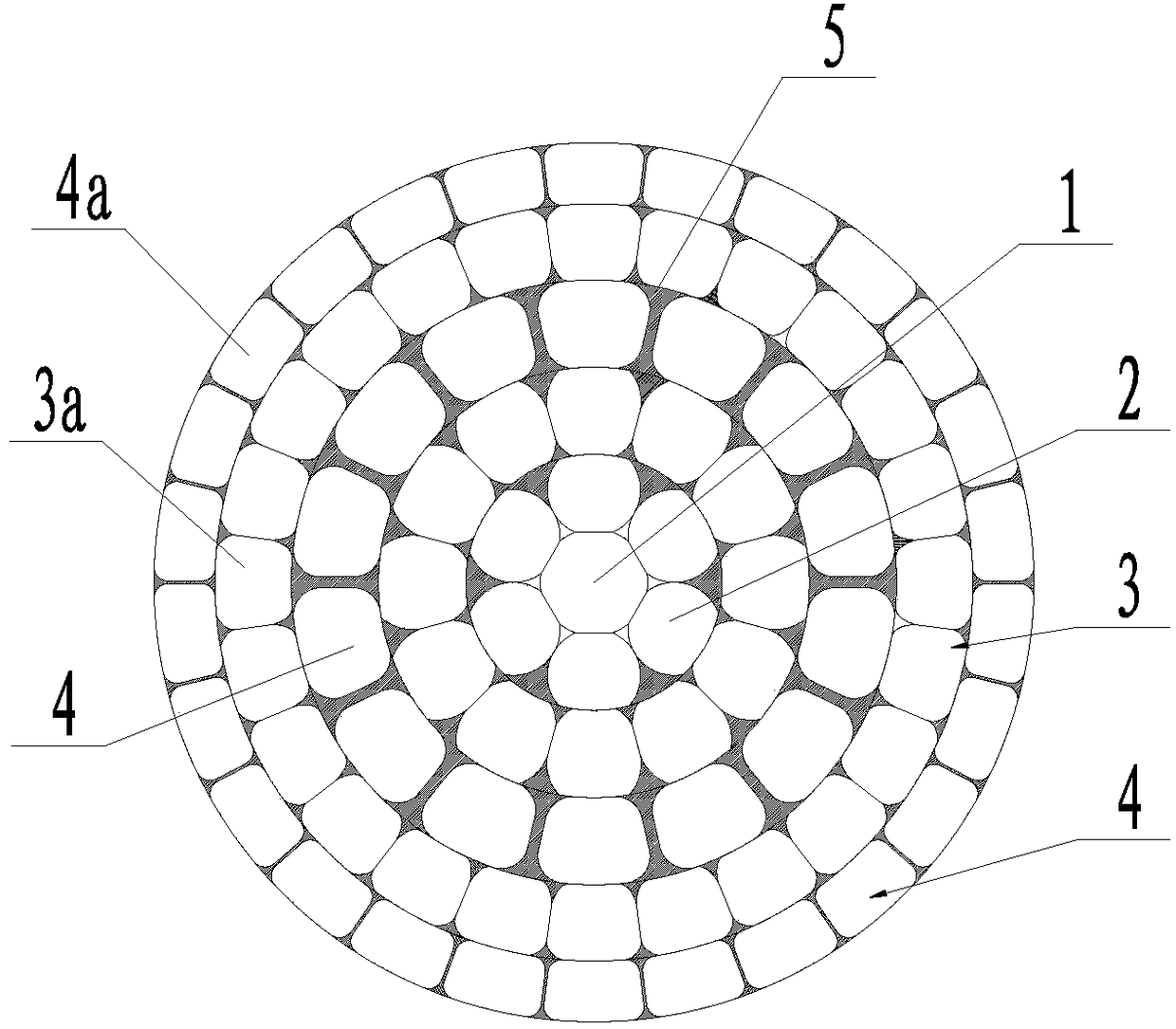

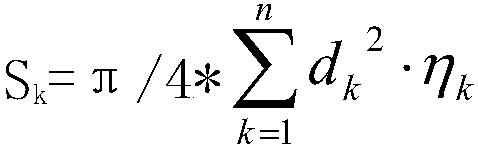

Process for manufacturing spliced conductor type cable

InactiveCN103500615AIncrease the degree of compressionSmall geometryInsulated cablesCable/conductor manufactureElectrical conductorEngineering

The invention discloses a process for manufacturing a spliced conductor type cable. The process includes the steps that metal blanks are utilized to draw conductors, the conductors comprise the inner conductors and the outer conductors, wherein the cross sections of the inner conductors are circular, the inner conductors are formed by a plurality of core wires of which the cross sections are semicircular or of a sector shape, the cross sections of the outer conductors are of a circular ring shape, the outer conductors and the inner conductors are spliced to form circular cross sections, and the outer conductors are formed by splicing a plurality of core wires of which the cross sections are of a tile shape; the core wires of the inner conductors and the core wires of the outer conductors are spliced into wires of which the cross sections are circular, and then the wires are twisted around a center shaft by a wire twisting machine, wherein the cross sections of the core wires are semicircular or of the sector shape or of the tile shape; inner insulating layers wrap the wires in an extrusion molding mode, the plurality of sets of wires wrapped by the inner insulating layers are circular, and outer sheathes wrap the plurality of sets of twisted wires. According to the process, the core wires are machined into the semicircular shape or the sector shape or the tile shape which can be spliced to the circular shape, then, the core wires are twisted to produce the wires, and therefore gaps among the core wires are reduced, the compaction degree of the wires is increased, and the geometric dimensions of the wires are reduced.

Owner:ANHUI ELECTRIC GRP SHARES

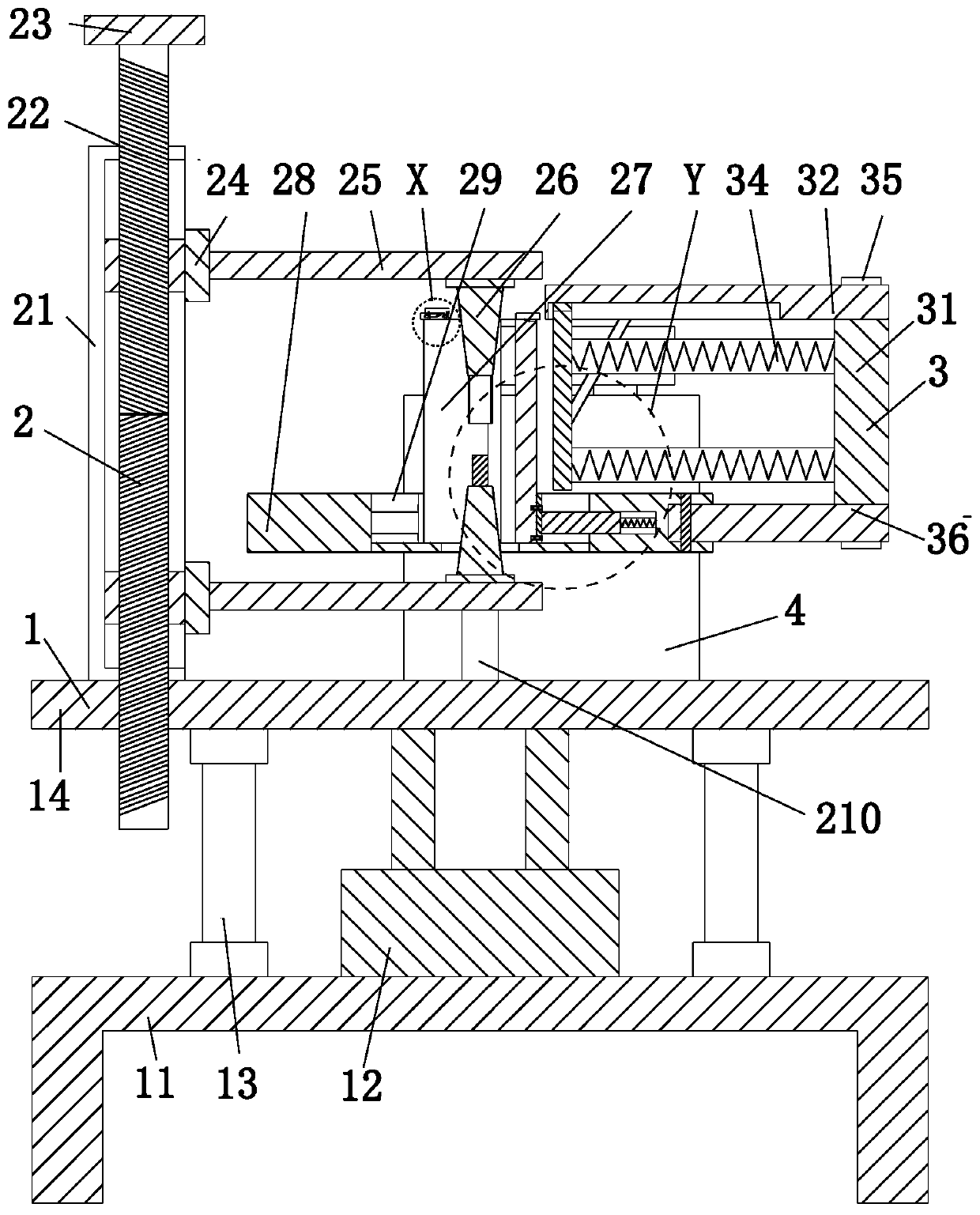

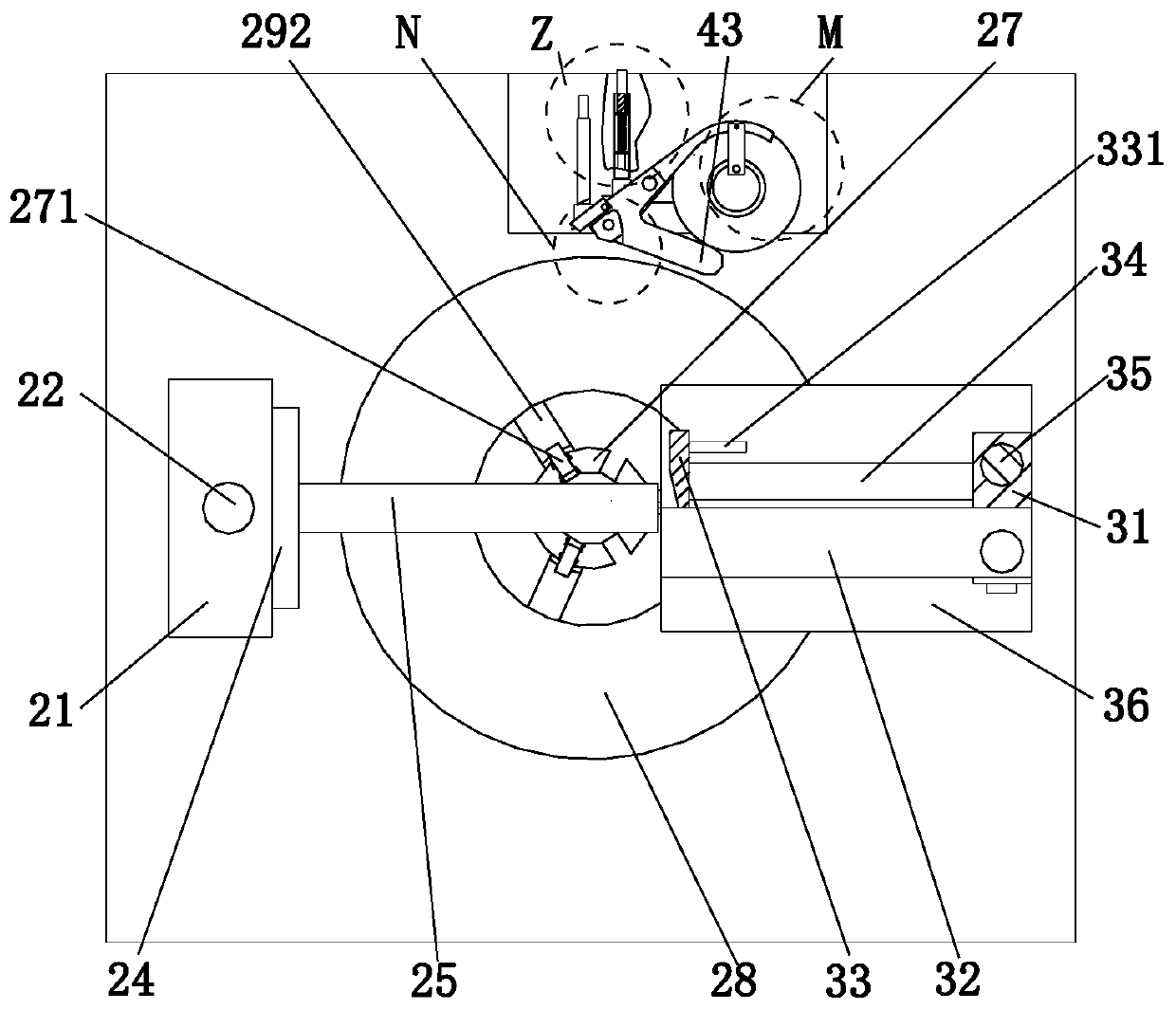

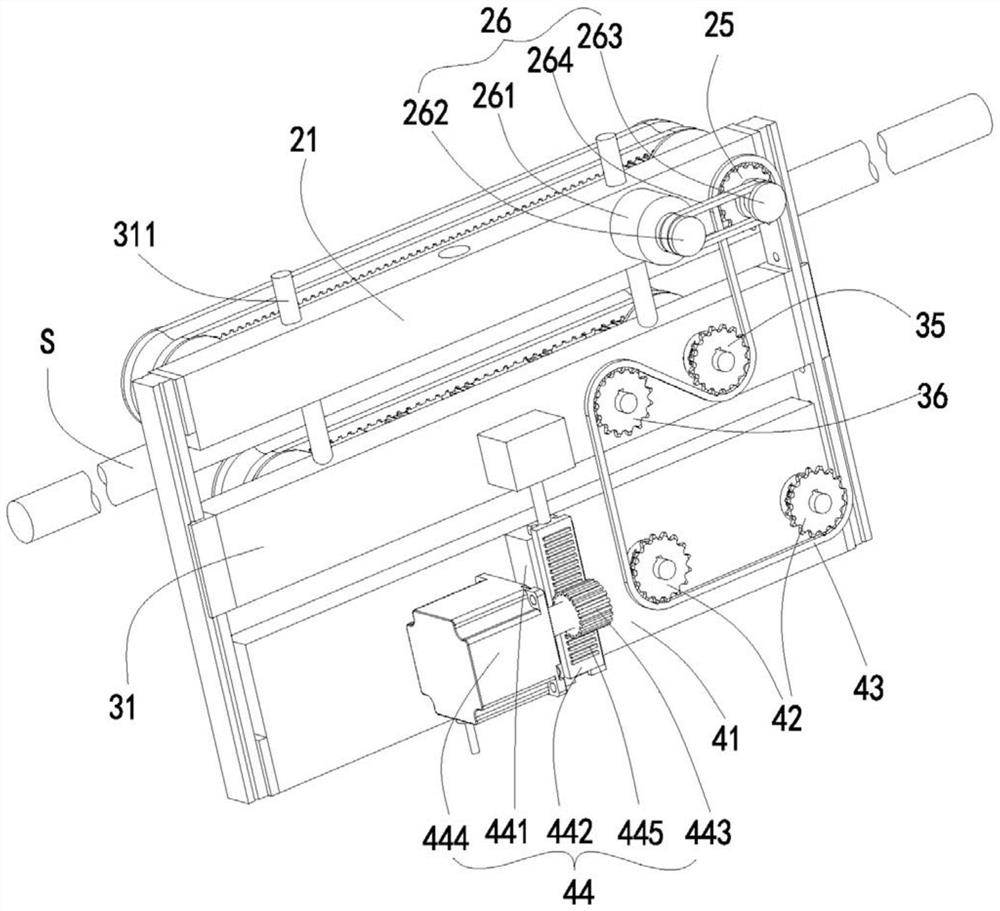

Stainless steel strip automatic winding machine

The invention relates to a stainless steel strip automatic winding machine. The machine comprises a transmission device, a core expanding device, a limiting device and a cloth pasting device; the coreexpanding device is mounted at the upper end of the transmission device; the limiting device is mounted at the right end of the core expanding device; the cloth pasting device is mounted at the backend of the upper end surface of the transmission device; and the cloth pasting device is positioned on the back side of the core expanding device. The stainless steel strip automatic winding machine adopts an adjustable multi-limiting design idea to wind stainless steel strips to meet different sizes and types of stainless steel strip coils, and adopts the limiting device to limit the stainless steel strips to reduce the deviation phenomenon occurrence probability and to greatly reduce the looseness phenomenon occurrence possibility.

Owner:日照市中腾机械有限责任公司

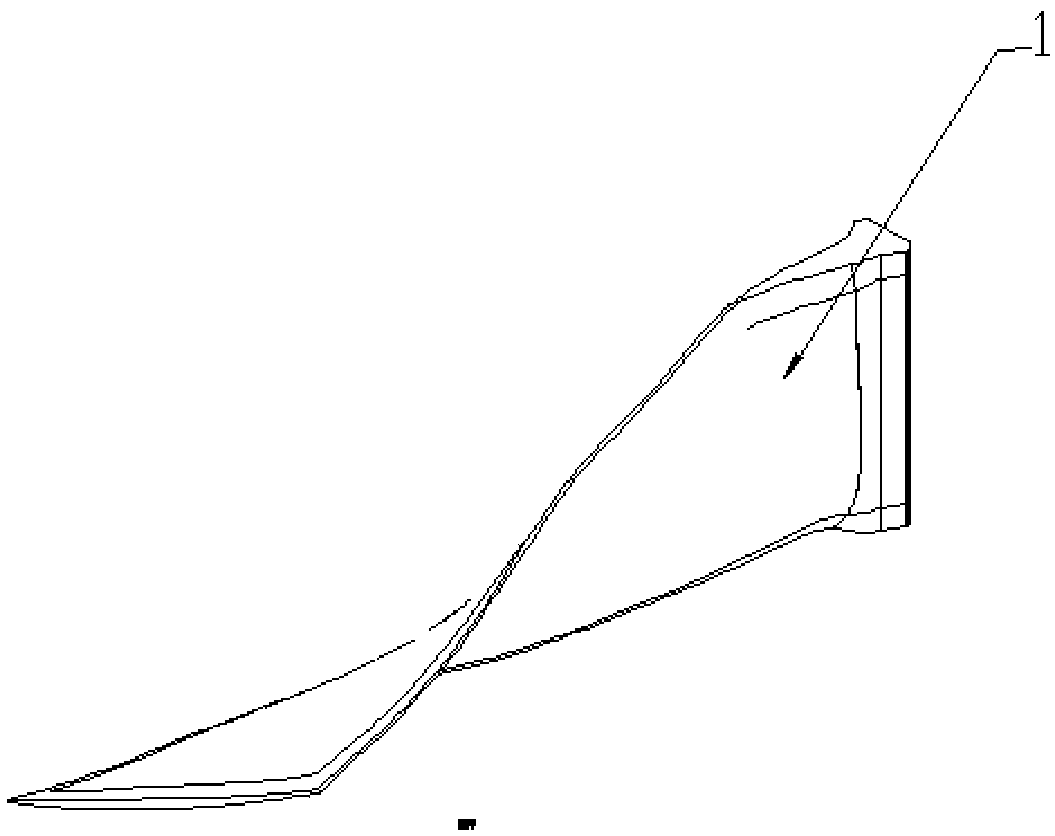

Resin transfer molding (RTM) method for composite blade

ActiveCN109304876AImprove pass rateImprove the degree of anti-displacementResin matrixComposite blade

The invention belongs to a liquid molding technology of resin matrix composites and relates to a resin transfer molding (RTM) method for a composite blade. According to the RTM method, by adjusting the compacted amounts, of a blade perform, in the margin areas of an upper half mold and a lower half mold, the compacted amounts are allowed to be higher than the compacted amounts, of the blade preform, in the molding area of the upper half mold and the lower half mold to increase the compaction degree, of the blade preform, in a peripheral margin area, so as to prevent the blade preform from moving in the mold closing process and increase the qualification rate of the braided composite blade molded by RTM; by adjusting the surface roughness degrees of the margin areas, of the upper half moldand the lower half mold, for blade molding, the surface roughness degrees are allowed to be higher than the roughness degrees of the molding areas of the upper half mold and the lower half mold to improve the capacity of preventing displacement of the blade preform in the peripheral margin area, so as to prevent the blade preform from moving during the mold closing process; and by increasing the numbers of surface bulges in the margin areas, of the upper half mold and the lower half mold, for blade molding, the capacity of preventing displacement of the blade preform is further improved, so asto fully ensure that the blade preform is prevented from moving in the mold closing process.

Owner:AVIC COMPOSITES

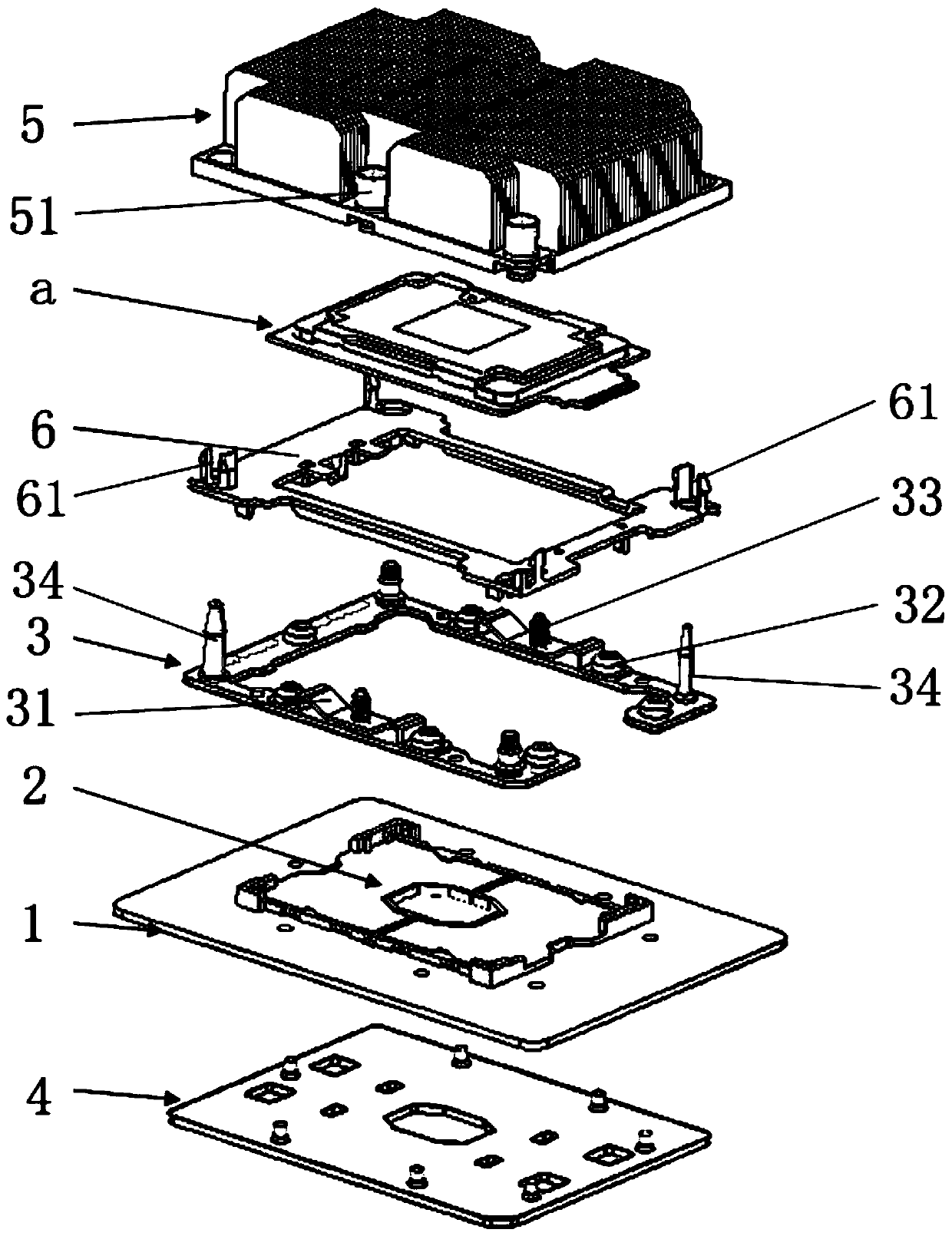

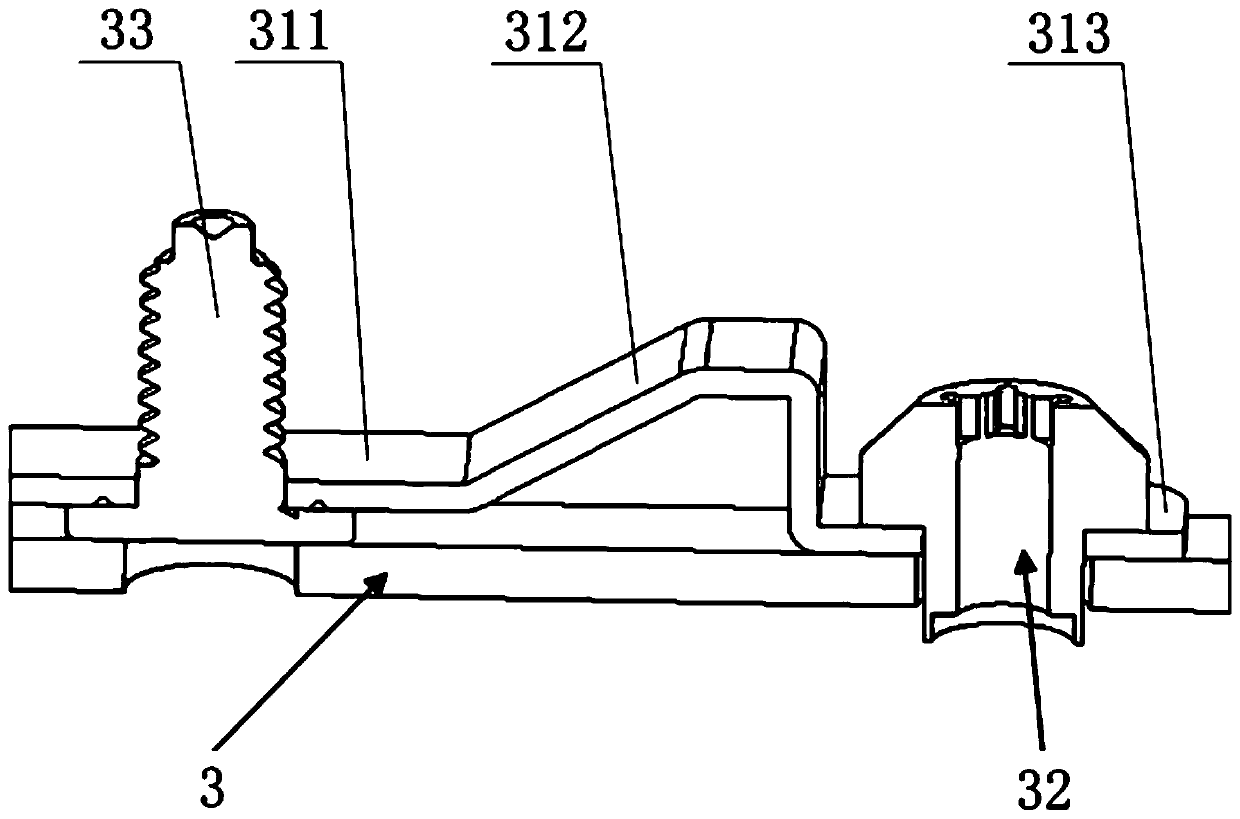

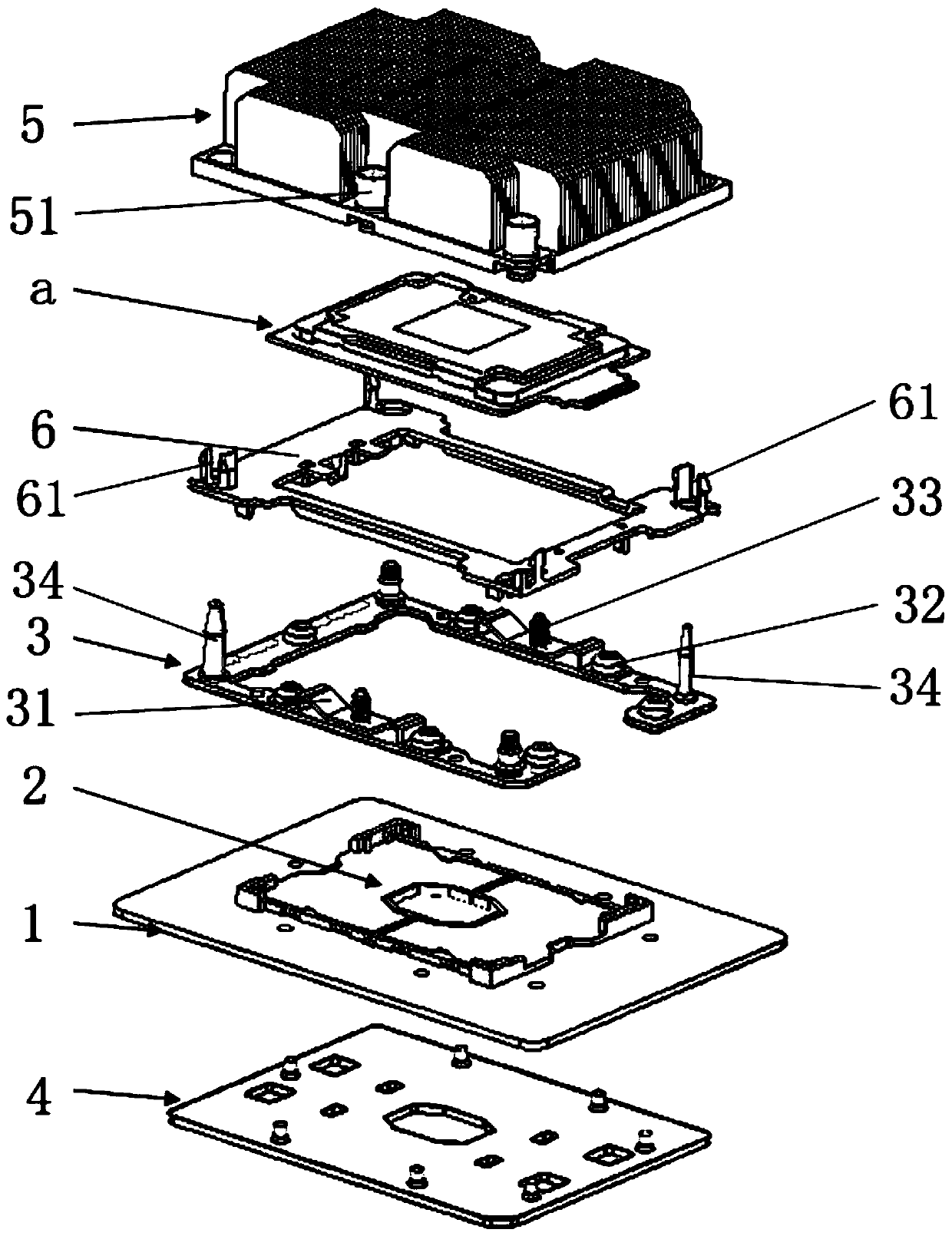

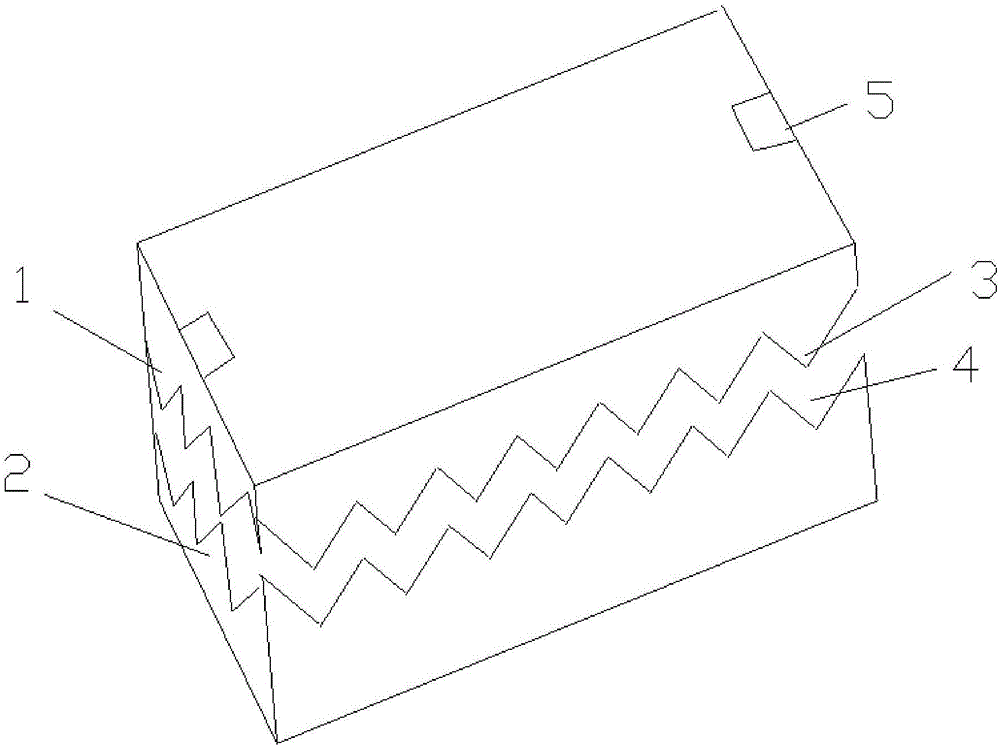

Server, mainboard and CPU mounting and fixing reinforcing module

InactiveCN111124069AAdjustable fit depthIncrease the degree of compressionDigital processing power distributionEngineeringMechanical engineering

The invention discloses a CPU mounting and fixing reinforcing module. The module comprises a PCB, a CPU slot, a CPU mounted in the CPU slot, a mounting lining plate arranged on the surface of the PCBand distributed around the CPU slot, a mounting back plate arranged on the back surface of the PCB, and a heat radiator shell mounted on the surface of the mounting lining plate and tightly pressed onthe surface of a CPU, an elastic plate capable of deforming in the vertical direction is arranged on the surface of the installation lining plate, the two ends of the elastic plate are connected withthe installation lining plate through first connecting pieces, and the installation lining plate and the installation back plate are tensioned through the first connecting pieces. A second connectingpiece is arranged on the elastic plate, and a pre-tightening adjusting piece used for being matching the second connecting piece and enabling the elastic plate to generate elastic deformation so as to tighten the radiator shell is arranged on the radiator shell. The structure of the CPU mounting module can be simplified, the dismounting and mounting efficiency is improved, the pressing force on the CPU is enhanced, and the heat dissipation performance and good physical contact are guaranteed. The invention also discloses a mainboard and a server, which have the above beneficial effects.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Sand box having stability

InactiveCN106734982AIncrease the degree of compressionQuality improvementMoulding flasksEngineeringCasting

The invention provides a sand box having stability. The sand box comprises an upper sand box and a lower sand box, wherein one or more protrusions are arranged at the lower end of the upper sand box; and one or more grooves adapted with the protrusions are formed in the upper end of the lower sand box. According to the sand box disclosed by the invention, the protrusions are arrange on the upper sand box, the grooves are formed in the lower sand box, and the protrusions and the grooves are adapted, so that after being covered, the upper sand box and the lower sand box are closed, the compacting degree of the upper sand box and the lower sand box can be increased; and the situation that during casting, the sand box is deformed caused by that molten iron heat sands in the sand box and are expanded is avoided, so that the quality of a casting is protected.

Owner:句容市有色金属铸造厂

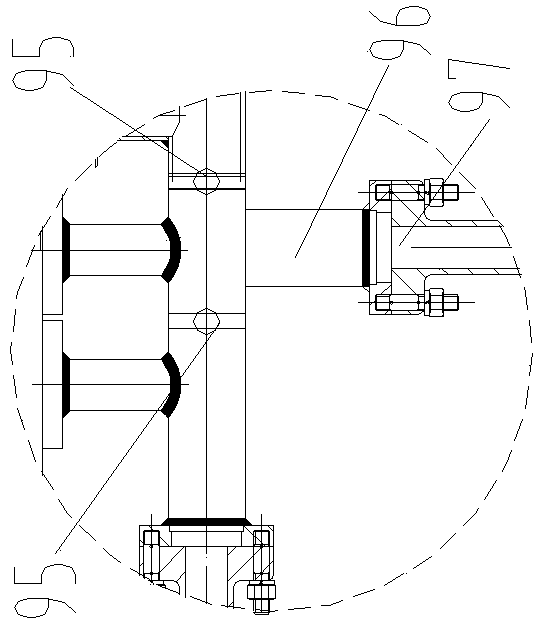

Large-section water-blocking conductor for submarine cable

ActiveCN106486182AIncrease the degree of compressionImprove water resistanceNon-insulated conductorsClimate change adaptationElectrical conductorWater block

The present invention discloses a large-section water-blocking conductor for a submarine cable. The large-section water-blocking conductor comprises a supporting core; n round wire stranded layers are arranged at the outer side of the supporting core, wherein n is a natural number greater than or equal to 1; a plurality of round wire compressing stranded layers are arranged at the outer side of the round wire stranded layers; the round wire pressing stranded layers and shaped wires stranded layers are arranged in a staggered manner; and water-blocking layers are arranged between the round wire stranded layers, the round wire pressing stranded layers and the shaped wires stranded layers. The compressing degree of the large-section water-blocking conductor is improved, and the overall deformation of the large-section water-blocking conductor is more uniform, and therefore, a water blocking effect can be effectively improved. The large-section water-blocking conductor has the advantages of simple structure, low transformation cost, long service life and the like.

Owner:CHONGQING TAISHAN CABLE +3

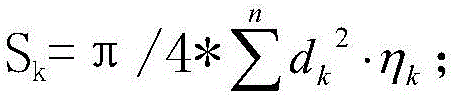

Pedal type film heat sealing machine with clamping mechanism

InactiveCN105398090AReduce work intensityReduce noiseEnvelopes/bags making machineryEnvironmental resistanceEngineering

The invention discloses a pedal type film heat sealing machine with a clamping mechanism. The pedal type film heat sealing machine comprises a workbench, a downward-press heat sealing mechanism, pedals, an electric resistance wire, a transmission mechanism and the clamping mechanism. The downward-press heat sealing mechanism is located above the electric resistance wire. The electric resistance wire is electrically connected with an external power source. The pedals control the downward-press heat sealing mechanism to ascend and descend through the transmission mechanism. The clamping mechanism is used for pressing the electric resistance wire to a workbench top of the workbench. The pedal type film heat sealing machine has the beneficial effects that the occupied space is small, the structure is simple, manufacturing cost is low and in the heat sealing process, energy consumption is small, noise is low, and environment friendliness is achieved.

Owner:ANQING XINSHUN PLASTIC CO LTD

Auxiliary fastening mechanism for thermos bottle plug

PendingCN113768378AImprove sealing efficiencyAvoid situations where it cannot be pulled outThermally-insulated vesselsEngineeringBottle

The invention relates to the technical field of articles for daily use, and discloses an auxiliary fastening mechanism for a thermos bottle plug, which comprises a plug body, an adjusting cavity is formed in the middle of the inner cavity of the plug body, a pull rod movably sleeves the middle of the plug body, a vent groove is formed in the middle of the pull rod, and an auxiliary block positioned on the outer side of the lower end of the pull rod movably sleeves the lower end of the adjusting cavity. The lower end of the auxiliary block is fixedly connected with an adjusting block, and the middle of the adjusting block is provided with an air suction groove communicating the vent groove with the lower portion of the plug body. Through the arrangement of an automatic pressurizing mechanism, when the interior of the thermos bottle is gradually cooled, internal air pressure is rapidly reduced, and a bottle plug is adsorbed to a bottle opening, under the action that negative pressure and a ball block the lower end of a vent groove, a pull rod moves downwards, and after an ejector rod ejects the ball upwards, an inner cavity of the bottle is communicated with the outside through the vent groove; therefore, outside air can quickly flow into the bottle to be pressurized, and the situation that the bottle plug cannot be pulled out due to the fact that the air pressure in the bottle is small is avoided.

Owner:查贵明

Anti-theft cable sleeve

ActiveCN110829300AIncrease the degree of compressionPrevent extractionElectrical apparatusBurglar alarm electric actuationPower cableEngineering

The invention discloses an anti-theft cable sleeve in the power cable technology field. A sleeve is included. An inner bottom wall of the sleeve is horizontally and slidably connected with a trigger piece. The trigger piece is provided with a clamping hole used for clamping a cable, a top of the trigger piece is provided with a cushion block with a height gradually increased from left to right, aV-shaped rod is hinged to the inner wall of the sleeve, one end of the V-shaped rod is connected with a pressing block used for pressing the cable, and the other end of the V-shaped rod abuts againstthe top of the cushion block. The pressing block is arranged to press the cable, when a lawbreaker pulls out the cable towards an external portion of the sleeve, the cable triggers the cushion block to gradually heighten the V-shaped rod, the pressing block rotates, and the cable is further pressed.

Owner:贵州首为电线电缆有限公司

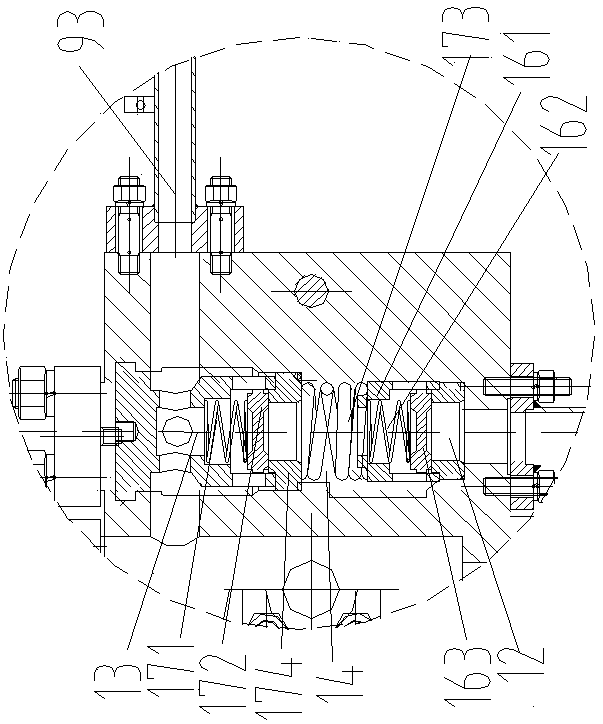

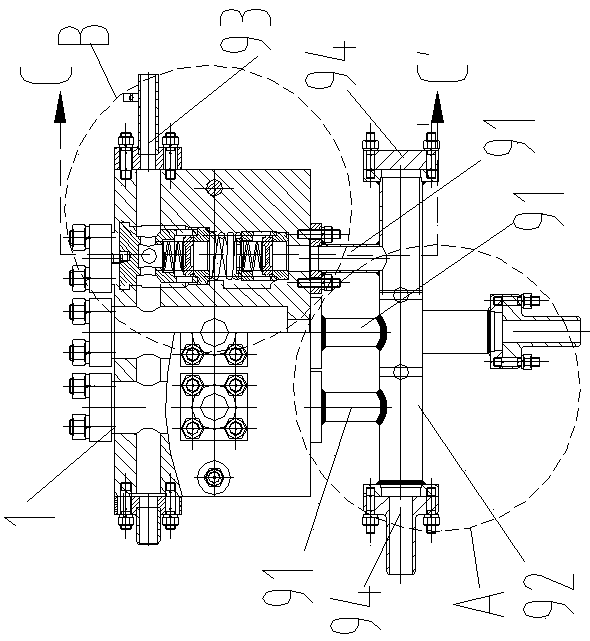

Convenient liquid mixing split plunger slurry pump

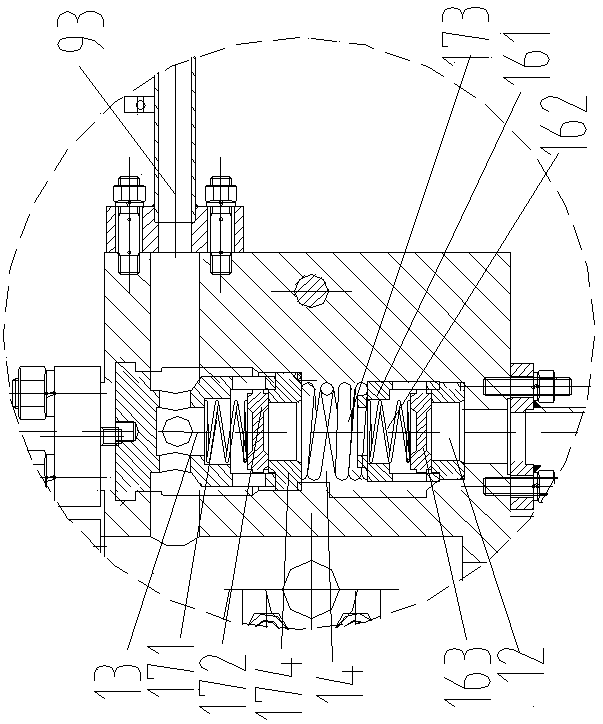

InactiveCN111022286AIncrease the degree of compressionAvoid enteringPositive displacement pump componentsPump controlPump pressurePlunger

The invention discloses a convenient liquid mixing split plunger slurry pump which comprises a hydraulic end and a power end. A plurality of liquid suction systems are arranged between the hydraulic end and the power end; each liquid suction system comprises a valve box assembly, a pull rod mounting cover and a transmission assembly; each valve box assembly is arranged at the hydraulic end, and each pull rod mounting cover is arranged at the power end; each transmission assembly comprises a pull rod, a pull rod sealing assembly, a plunger, a plunger sealing assembly, a plunger horizontal position fine adjustment assembly and a connecting rod; the plunger horizontal position fine adjustment assembly comprises a plunger end cover, two metal inner clamping rings and two elastic outer clampingrings; a liquid inlet of each valve box assembly is connected to a liquid inlet pipe; and a liquid outlet of each valve box assembly is connected to a liquid outlet pipe. The slurry pump can interchange single liquid, double liquids and multiple liquids, can mix liquid in different proportions, is stable in liquid suction pump pressure and is uniform to mix the liquids.

Owner:SHANDONG ZHONGTAN MACHINERY

An ironing device for suit processing

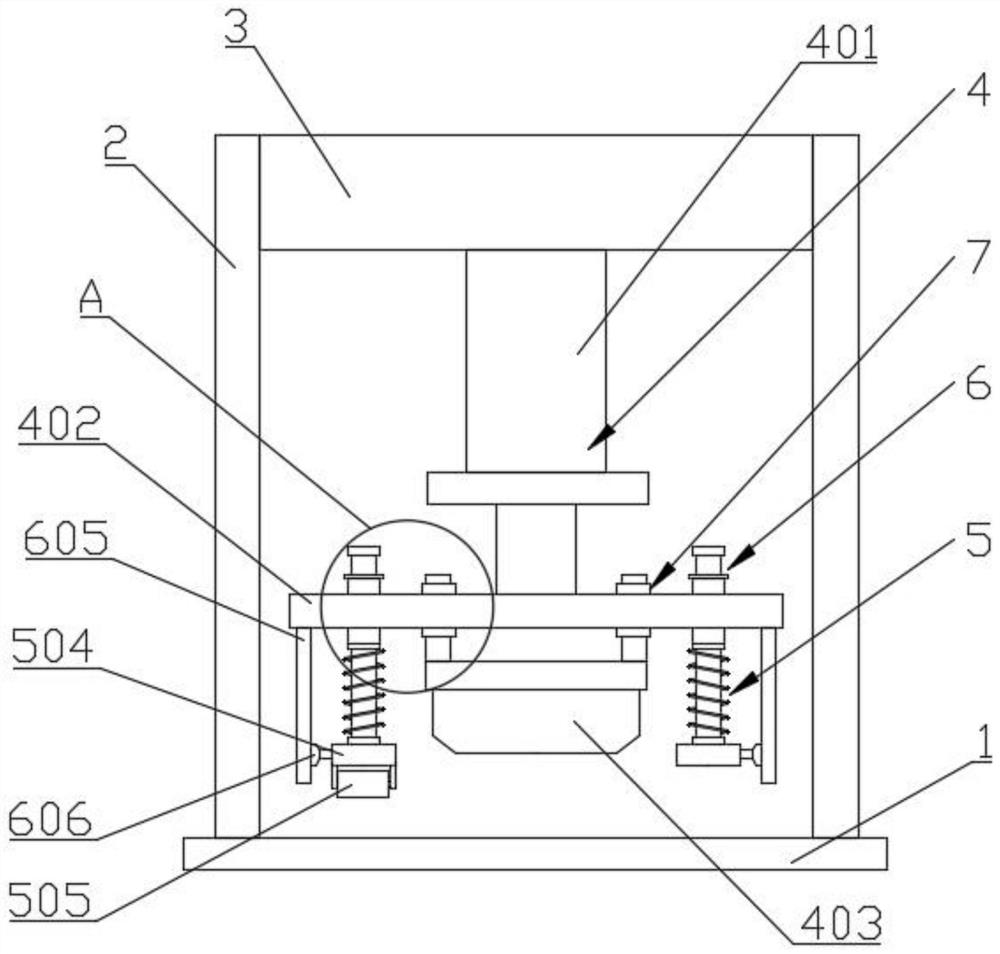

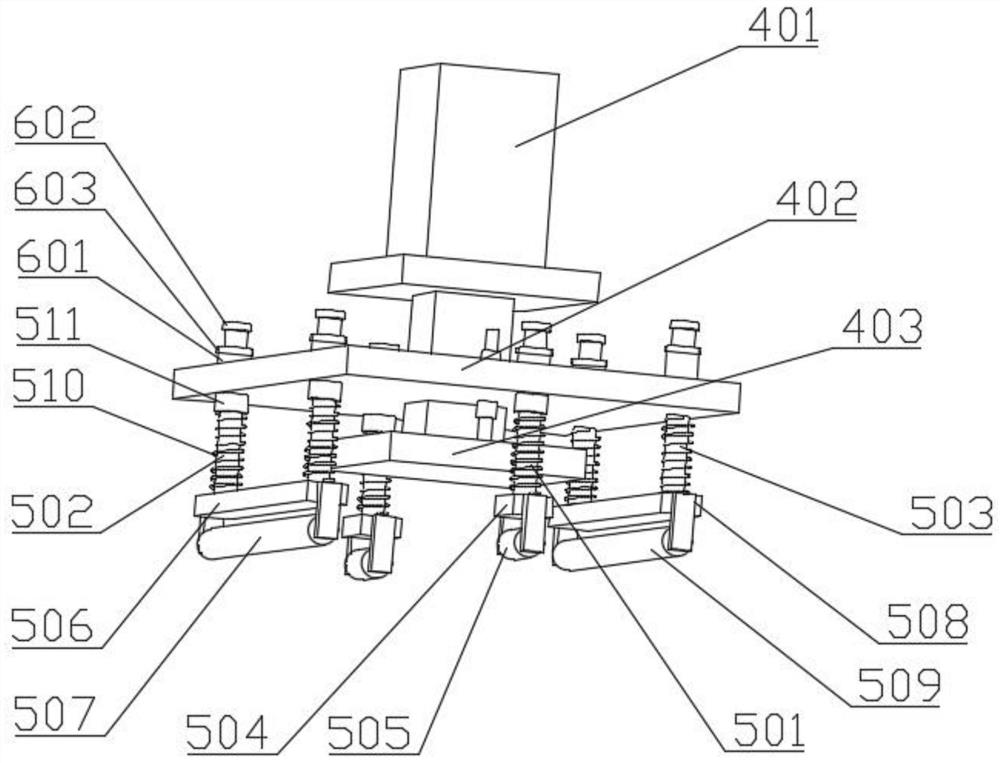

ActiveCN111472152BEasy ironingSmooth ironing processFinal product manufactureIroning apparatusMechanical engineeringIndustrial engineering

The invention discloses an ironing device for suit processing, comprising a working platform for placing suits to be processed, a frame is arranged on the working platform, a moving device is arranged on the frame, and an output end of the moving device is arranged with a Lifting and ironing device, the moving device drives the lifting and ironing device to move above the working platform, during the moving process, the lifting and ironing device irons the suit, the mounting plate is provided with a pressing component, and the pressing component and the mounting plate are arranged between the pressing components and the mounting plate. A pressing and adjusting component is provided, and a mode adjusting component is arranged between the ironing component and the mounting plate. The pressing component can press and flatten the suit around the ironing area, and the pressing and adjusting component can change the pressing force of the pressing component on the suit. The mode adjustment component can determine the distance between ironing and the suit according to the material of the suit, iron suits of different materials in a targeted manner, improve the ironing effect of the suit, and avoid improper ironing methods. Damage caused by suits.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

A stainless steel strip automatic winding machine

The invention relates to a stainless steel strip automatic winding machine. The machine comprises a transmission device, a core expanding device, a limiting device and a cloth pasting device; the coreexpanding device is mounted at the upper end of the transmission device; the limiting device is mounted at the right end of the core expanding device; the cloth pasting device is mounted at the backend of the upper end surface of the transmission device; and the cloth pasting device is positioned on the back side of the core expanding device. The stainless steel strip automatic winding machine adopts an adjustable multi-limiting design idea to wind stainless steel strips to meet different sizes and types of stainless steel strip coils, and adopts the limiting device to limit the stainless steel strips to reduce the deviation phenomenon occurrence probability and to greatly reduce the looseness phenomenon occurrence possibility.

Owner:日照市中腾机械有限责任公司

Spliced conductor type cable

InactiveCN103500602AIncrease the degree of compressionSmall geometryInsulated cablesInsulated conductorsElectrical conductorEngineering

The invention discloses a spliced conductor type cable. The spliced conductor type cable comprises a plurality of conductors, inner insulating layers wrap wires and are twisted around a center, and an outer insulating layer wraps the whole cable; the conductors are formed by twisting the inner conductors and the outer conductors, the cross sections of the inner conductors are circular, the inner conductors are formed by a plurality of core wires of which the cross sections are semicircular or of a sector shape, the cross sections of the outer conductors are of a circular ring shape, the outer conductors and the inner conductors are spliced to form circular cross sections, and the outer conductors are formed by splicing a plurality of core wires of which the cross sections are of a tile shape. According to the spliced conductor type cable, the core wires are machined into the semicircular shape or the sector shape or the tile shape which can be spliced to the circular shape, then, the core wires are twisted together to produce the wires, and therefore gaps among the core wires are reduced, the compaction degree of the wires is increased, and the geometric dimensions of the wires are reduced.

Owner:ANHUI ELECTRIC GRP SHARES

Split type oil pressure airtight plunger mud pump convenient in fluid mixing

InactiveCN111059013AAdjust the degree of compressionIncrease the degree of compressionPositive displacement pump componentsPump controlEngineeringPump pressure

The invention discloses a split type oil pressure airtight plunger mud pump convenient in fluid mixing. The split type oil pressure airtight plunger mud pump comprises a fluid force end and a power end, wherein a plurality of fluid sucking systems are arranged between the fluid force end and the power end; each fluid sucking system comprises a valve box assembly, a pull rod mounting sleeve and a transmission assembly; each transmission assembly comprises a pull rod, a pull rod sealing assembly, a plunger and a plunger sealing assembly; each pull rod is connected with the corresponding plungerthrough a corresponding adjusting and connecting assembly; each pull rod is mounted on the corresponding pull rod mounting sleeve through the corresponding pull rod sealing assembly; a protecting device is arranged between the end adjacent to each pull rod mounting sleeve, of the corresponding plunger and the corresponding pull rod mounting sleeve; a fluid inlet of each valve box assembly is connected with a corresponding fluid inlet pipe; and a fluid outlet of each valve box assembly is connected with a fluid outlet pipe. Through the adoption of the split type oil pressure airtight plunger mud pump disclosed by the invention, exchanging of single fluid, double fluid and multiple fluid can be realized, the mixing of the fluid of different compounding ratios can be realized, the fluid sucking pump pressure is stable, and the mixing of the fluid is uniform.

Owner:SHANDONG ZHONGTAN MACHINERY

Rolling device for compressing insole

The invention discloses a rolling device for compressing an insole. The device comprises a workbench of which the workbench face is rectangular, a groove is formed in the workbench, a storage plate for placing insoles is mounted in the groove, gliding rails for the storage plate to slide in the direction of the long side of the workbench are arranged on groove walls of the two sides of the groove, at least two rollers are arranged above the groove, all the rollers are sequentially arranged in the direction of the long side of the workbench, the central axes of the rollers are parallel to the broadside of the workbench, a pressing plate is arranged above the rollers, through holes for each roller to penetrate through the pressing plate are formed above the pressing plate, the through holes correspond to the rollers one by one, a fixed plate is connected above the pressing plate, and each roller is fixedly connected with the fixed plate. According to the rolling device for compressing the insole, the dispersion degree of adhesive among all layers of the insole and the compaction degree among all the layers of the insole are improved, and therefore the connection among all layers of the insole is firmer.

Owner:CHENGDU LIXIN SCI & TECH

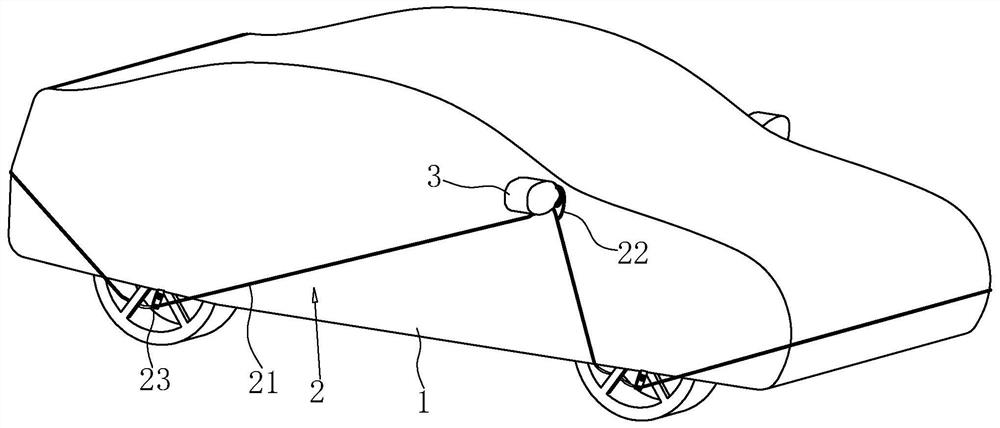

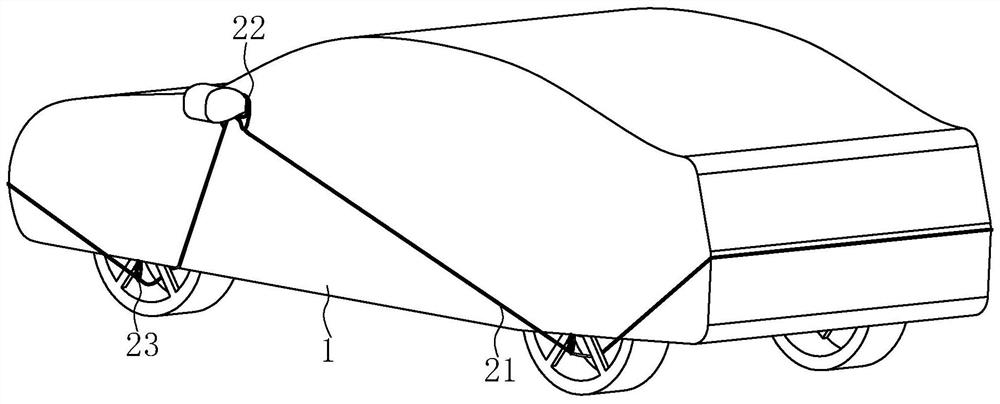

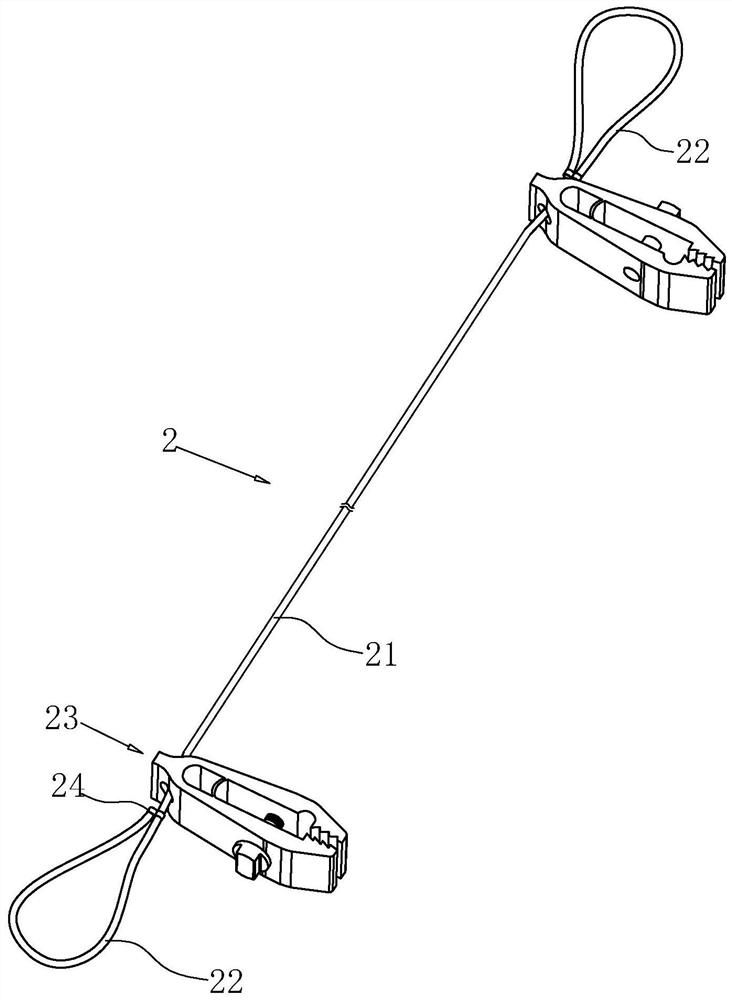

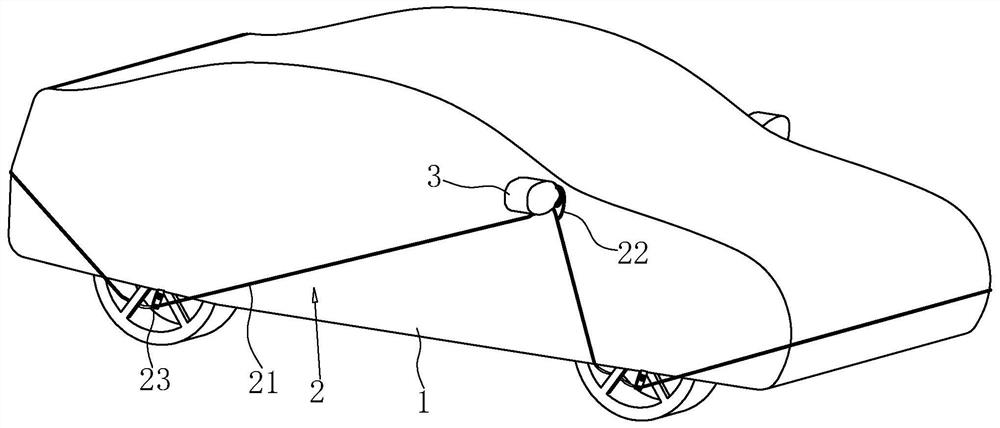

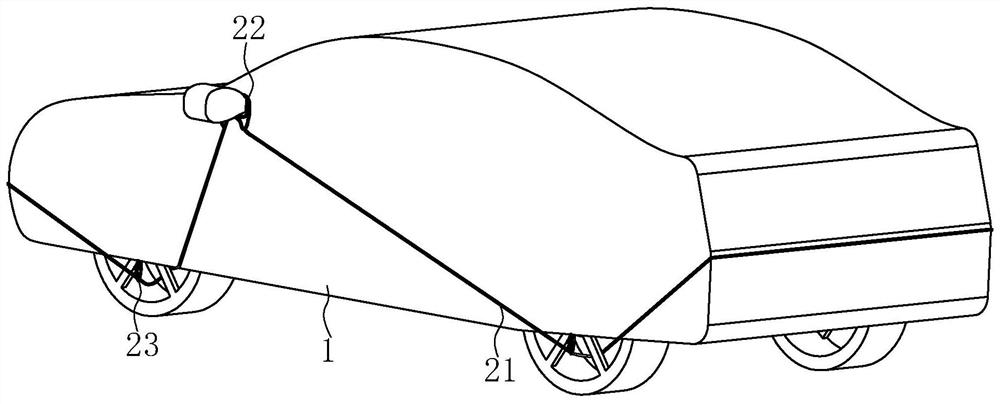

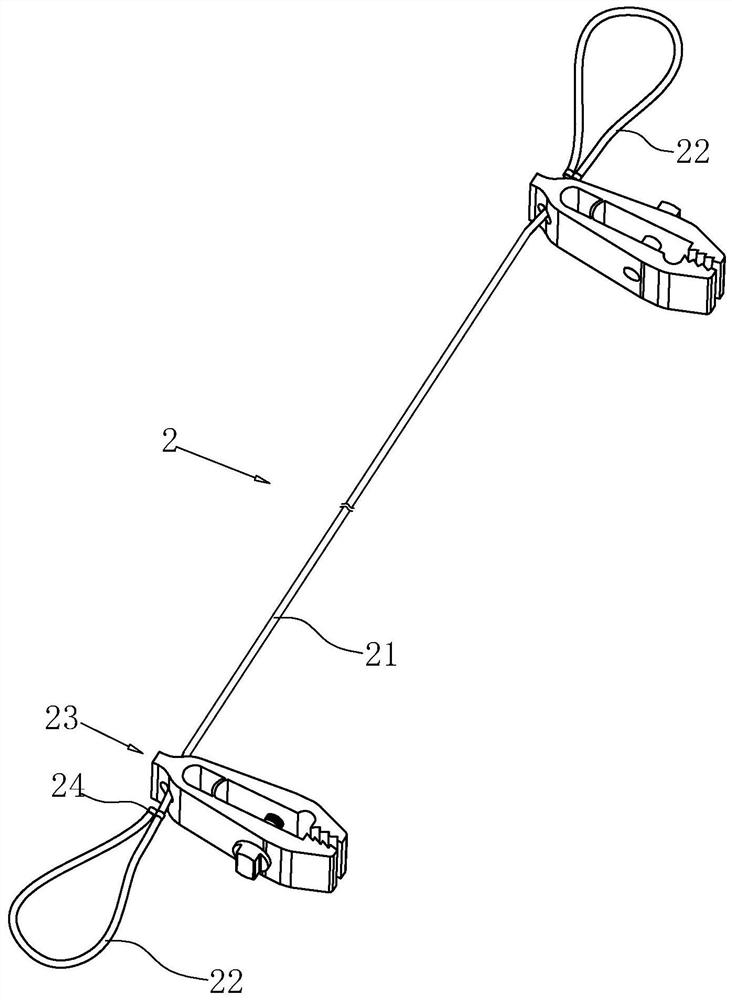

A restraint system for automobile cover and restraint method thereof

ActiveCN112590517BImprove stabilityConvenience constraintsRemovable external protective coveringsStructural engineeringControl theory

The present application relates to a restraint system for an automobile cover and a method thereof, comprising a restraint assembly, the restraint assembly comprising a restraint rope, a collar and a clamping member; two collars are provided, and the two collars are respectively provided At both ends of the restraining rope, the two collars are respectively sleeved on the two rear-view mirrors of the automobile covered with the automobile cover, and the restraining rope between the two collars is pressed tightly to restrain the automobile cover on the vehicle body; There are two clamping parts, the two clamping parts are arranged on the restraining rope at intervals, and the two clamping parts are used for clamping on both sides edges of the opening of the car cover. The present application has the effect of improving the stability of the vehicle cover restrained on the vehicle body.

Owner:陈艺聪

Restraint system of automobile cover and restraint method thereof

ActiveCN112590517AImprove stabilityConvenience constraintsRemovable external protective coveringsStructural engineeringLantern

The invention relates to a restraint system and method for an automobile cover, and the restraint system comprises a restraint assembly which comprises a restraint rope, lantern rings, and clamping parts. The number of the lantern rings is two, the two lantern rings are arranged at the two ends of the restraint rope respectively, two automobile rear view mirrors covered with the automobile cover are sleeved with the two lantern rings respectively, and the restraint rope located between the two lantern rings tightly presses and restrains the automobile cover on an automobile body. The number ofthe clamping parts is two, the two clamping parts are arranged on the restraining rope in a spaced mode, and the two clamping parts are used for being clamped on the edges of the two sides of an opening of the automobile cover. The restraint system has the effect of improving the stability of restraining the automobile cover on the automobile body.

Owner:陈艺聪

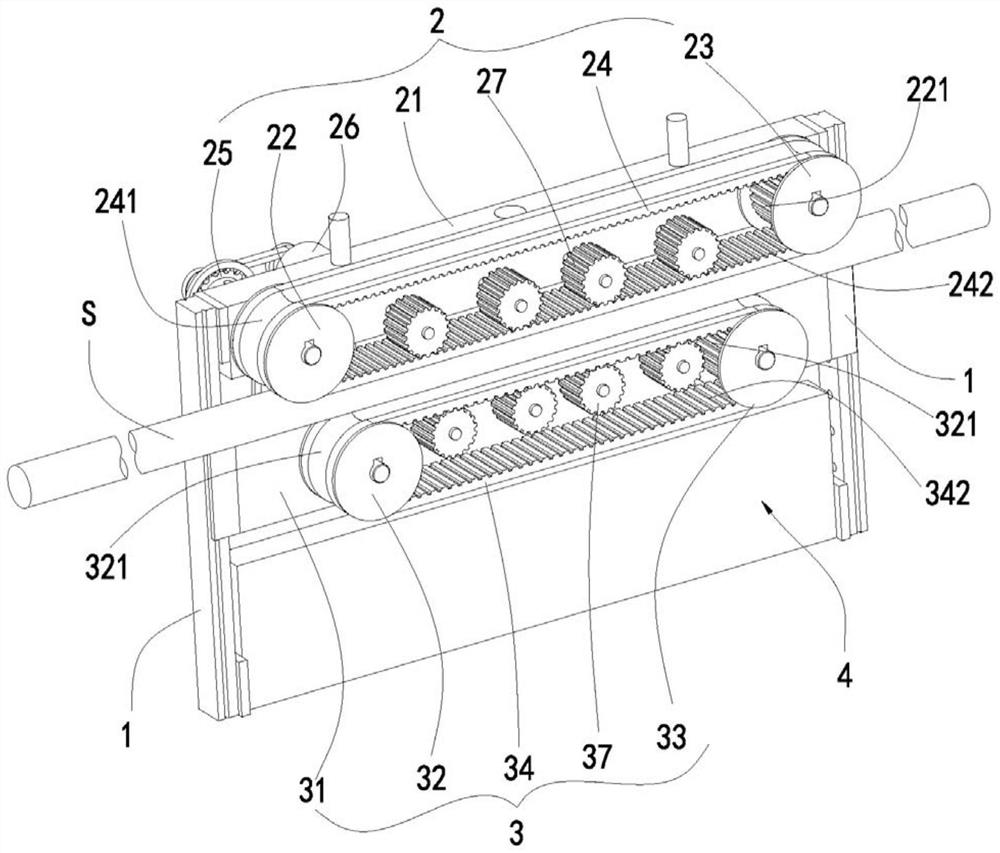

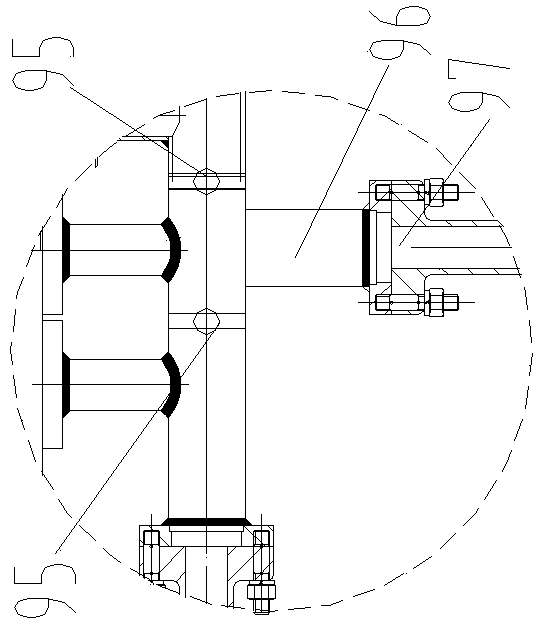

A transmission line operation robot

ActiveCN112600118BImprove climbing abilityPrevent slippingManipulatorApparatus for overhead lines/cablesDrive wheelSprocket

The invention proposes a power transmission line operation robot, comprising: guide rails, two vertically arranged; an upper wheel assembly, including an upper mounting plate, and one side of the upper mounting plate is provided with an upper driving wheel, an upper driven wheel and an upper timing belt The other side of the upper mounting plate is provided with an upper driving sprocket connected with the upper driving wheel; the lower wheel assembly includes a lower driving wheel, a lower driven wheel and a lower synchronous belt arranged on one side of the lower mounting plate, and the lower mounting plate is another A lower driving sprocket connected to the lower driving wheel is arranged on one side, and a tensioning sprocket is arranged on one side of the lower driving sprocket; The sprocket, the lower driving sprocket, the tensioning sprocket and the steering sprocket are connected through a chain drive, and the fixing plate is also provided with a driving device for driving the lower wheel assembly to move up and down. The invention can greatly improve the climbing ability of the power transmission line operation robot by providing sufficient pressing force.

Owner:武汉露能科技有限公司

A large-section water-blocking conductor for submarine cables

ActiveCN106486182BIncrease the degree of compressionImprove water resistanceNon-insulated conductorsClimate change adaptationOcean bottomElectrical conductor

The present invention discloses a large-section water-blocking conductor for a submarine cable. The large-section water-blocking conductor comprises a supporting core; n round wire stranded layers are arranged at the outer side of the supporting core, wherein n is a natural number greater than or equal to 1; a plurality of round wire compressing stranded layers are arranged at the outer side of the round wire stranded layers; the round wire pressing stranded layers and shaped wires stranded layers are arranged in a staggered manner; and water-blocking layers are arranged between the round wire stranded layers, the round wire pressing stranded layers and the shaped wires stranded layers. The compressing degree of the large-section water-blocking conductor is improved, and the overall deformation of the large-section water-blocking conductor is more uniform, and therefore, a water blocking effect can be effectively improved. The large-section water-blocking conductor has the advantages of simple structure, low transformation cost, long service life and the like.

Owner:CHONGQING TAISHAN CABLE +3

Flat cable penetration sealing device with high sealing performance in dynamic environment

ActiveCN106439240BMeet the penetration sealIncrease the degree of compressionPipesCable inlet sealing meansEngineeringCushion

The invention discloses a flat cable penetration sealing device with high sealing property in a dynamic environment. According to the device, a flat cable is embedded into a gap of an elastic sealing block, the elastic sealing block is put into a circular hole of a sealing cabin cover, two cushion blocks are respectively mounted on two small end faces of the elastic sealing block, a sealing gland and the sealing cabin cover are in fastened connection by screwing the bolts, the elastic sealing block is axially extruded by the sealing gland so as to gradually deform outwards, so that cone seal is formed between the sealing gland and a circular truncated cone-shaped hole of the sealing cabin cover, plane seal is formed between the elastic sealing block and the flat cable, and internal and external dual seal functions are realized. The section diameter of the circular truncated cone-shaped hole of the sealing cabin cover is gradually reduced, the compression degree of the elastic sealing block is gradually increased, and high sealing property can be achieved, so that the sealing property with the same order as that of the cone seal is achieved, and flat cable penetration seal with high sealing property in the dynamic environment is met.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

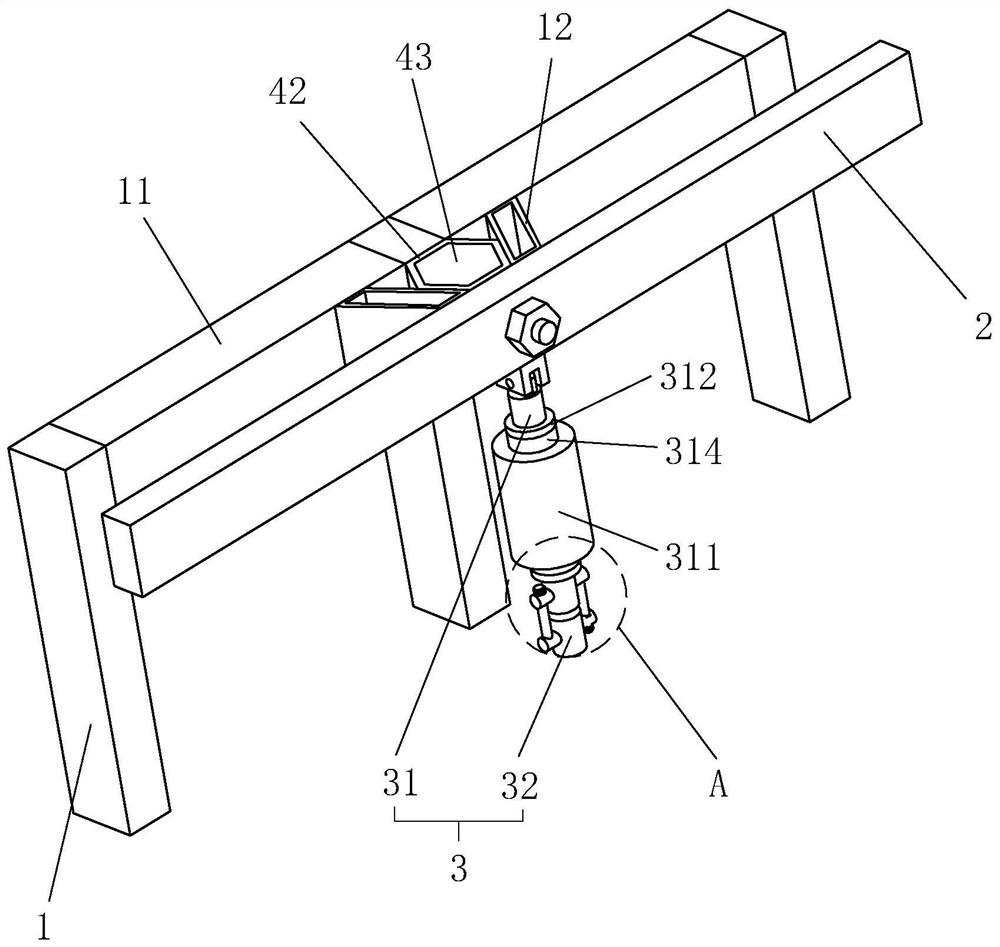

Anti-collision structure of road bridge

ActiveCN110607745BReduce impactNot easy to damageBridge structural detailsRoadway safety arrangementsImpact

The invention relates to an anti-collision structure of a road bridge, and belongs to the technical field of anti-collision structures. The anti-collision structure comprises an upright post, whereinthe upright post is fixedly connected to the ground; the upright post is fixedly connected with a horizontal cross bar; the cross bar is provided with an impact transfer assembly; the impact transferassembly comprises a vertical rod and a connecting ring; the vertical rod is hinged at the bottom of the cross bar; the hinge axis of the vertical rod is parallel to the length direction of the crossbar; the vertical rod is vertically arranged; the connecting ring is embedded in the ground; the bottom of the vertical rod is hinged to the connecting ring; and a buffer is fixedly connected betweenthe cross bar and the upright post. The anti-collision structure has the effect of reducing the damage possibility of the post and improving the vehicle protection capability.

Owner:福建华成路桥工程有限公司

A kind of rtm forming method of composite material blade

ActiveCN109304876BIncrease the degree of compressionPhenomenon that prevents position shiftingResin matrixTransfer molding

The invention belongs to a liquid molding technology of resin matrix composites and relates to a resin transfer molding (RTM) method for a composite blade. According to the RTM method, by adjusting the compacted amounts, of a blade perform, in the margin areas of an upper half mold and a lower half mold, the compacted amounts are allowed to be higher than the compacted amounts, of the blade preform, in the molding area of the upper half mold and the lower half mold to increase the compaction degree, of the blade preform, in a peripheral margin area, so as to prevent the blade preform from moving in the mold closing process and increase the qualification rate of the braided composite blade molded by RTM; by adjusting the surface roughness degrees of the margin areas, of the upper half moldand the lower half mold, for blade molding, the surface roughness degrees are allowed to be higher than the roughness degrees of the molding areas of the upper half mold and the lower half mold to improve the capacity of preventing displacement of the blade preform in the peripheral margin area, so as to prevent the blade preform from moving during the mold closing process; and by increasing the numbers of surface bulges in the margin areas, of the upper half mold and the lower half mold, for blade molding, the capacity of preventing displacement of the blade preform is further improved, so asto fully ensure that the blade preform is prevented from moving in the mold closing process.

Owner:AVIC COMPOSITES +1

A high-temperature flue manhole door device

A manhole door device of a high-temperature flue comprises a manhole door frame, wherein a door cover plate and a sealing plate are embedded in two sides of the manhole door frame respectively to form a door body adopting a hollow structure, an inner-layer heat-insulating bag assembly and an outer-layer heat-insulating bag assembly are arranged inside the door body, the inner-layer heat-insulating bag assembly is close to the sealing plate, the outer-layer heat-insulating bag assembly is close to the door cover plate, and a handle and a tumbler mechanism are arranged on the door cover plate. The manhole door device is reasonable in structural design and ingenious and novel in concept and adopts the inner-and-outer-layer soft heat-insulating bag structure, so that heat-insulating cloth can be uncovered for addition of aluminium silicate fiber felt as required each time of overhauling, and the circularity of heat-insulating bags is kept. Angle steel on an outer-layer heat-insulating bag is 30 mm wide, and certain pre-tightening space is provided when the door cover plate is closed, so that the outer-layer heat-insulating bag and an inner-layer heat-insulating bag are attached to each other more compactly, and smoke channeling is avoided.

Owner:中国船舶重工集团公司第七〇三研究所

An anti-theft cable sleeve

ActiveCN110829300BIncrease the degree of compressionPrevent extractionElectrical apparatusBurglar alarm electric actuationPower cableStructural engineering

The application discloses an anti-theft cable sleeve in the technical field of power cables, which includes a sleeve, the inner bottom wall of the sleeve is horizontally slidably connected with a trigger piece, and the trigger piece is provided with a clamping hole for a caliper cable. The top of the trigger is provided with pads that gradually increase in height from left to right, and a V-shaped rod is hinged on the inner wall of the sleeve, and one end of the V-shaped rod is connected with a pressing block for compressing the cable. The other end of the glyph bar abuts against the top of the spacer. By setting the pressing block to compress the cable, when criminals pull out the cable toward the outside of the casing, the cable will trigger the spacer to gradually raise the V-shaped rod, so that the pressing block rotates and further compresses the cable.

Owner:贵州首为电线电缆有限公司

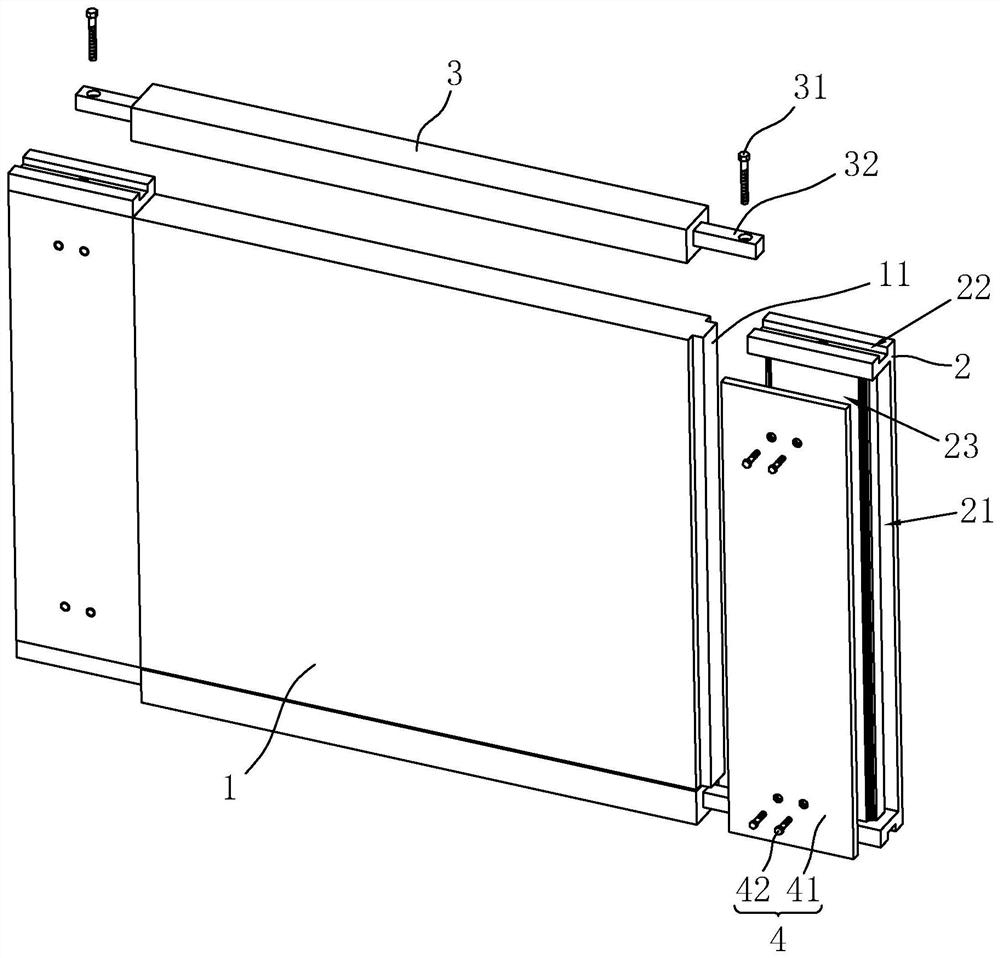

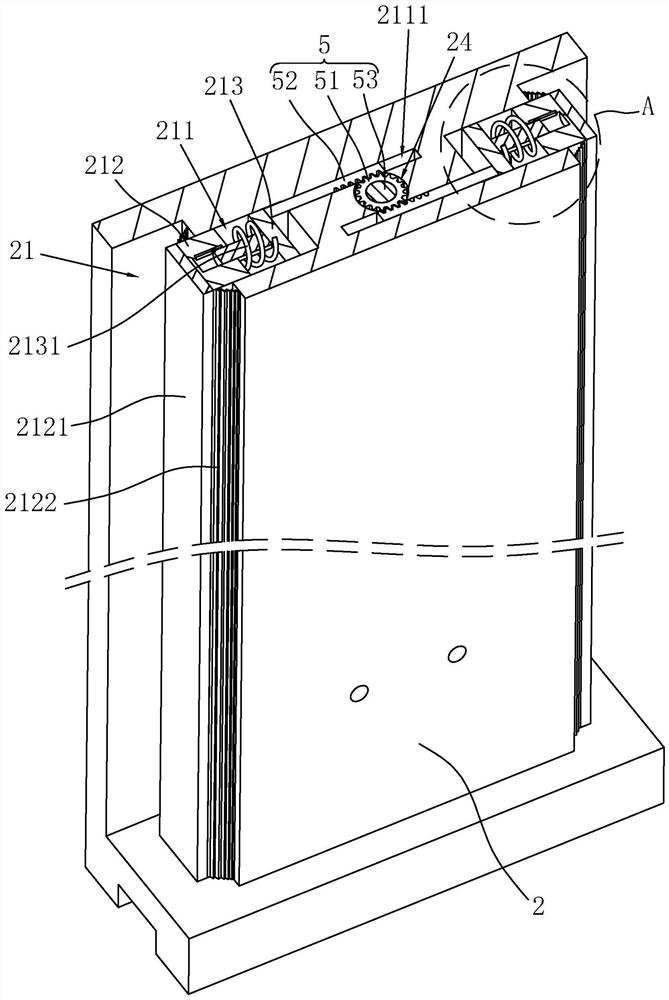

Fabricated building structure and building method of house

InactiveCN114525844AImprove insulation effectEasy accessWallsHeat proofingArchitectural engineeringHeat conservation

The invention relates to a house assembly type building structure which comprises prefabricated wallboards and fixing columns, the fixing columns are used for being installed at the connecting positions of the prefabricated wallboards, installation blocks are fixedly arranged on the two sides of each prefabricated wallboard, and installation grooves allowing the installation blocks to be inserted therein are formed in the fixing columns. A containing groove is formed in the side wall of the mounting groove in the direction perpendicular to the fixing column, a sealing rod is arranged in the containing groove in a sliding mode, and a sealing strip is arranged at the end, away from the bottom wall of the containing groove, of the sealing rod and used for abutting against the mounting block. The fixing column is provided with an elastic piece used for driving the sealing rod to slide in the direction away from the bottom wall of the containing groove, and the fixing column is further provided with a fixing assembly used for fixing the prefabricated wallboard. The prefabricated building has the effect that the overall heat preservation performance of the prefabricated building is good.

Owner:四川竹沅建设有限公司

Plunger mud pump comprising split type plunger assemblies

InactiveCN111059014AIncrease the degree of compressionReduce wearPositive displacement pump componentsPumpsStructural engineeringMechanical engineering

The invention discloses a plunger mud pump comprising split type plunger assemblies. The plunger mud pump comprises a fluid end and a power end. A plurality of fluid pumping systems are arranged between the fluid end and the power end. Each fluid pumping system comprises a valve box assembly, a pull rod mounting sleeve and a transmission assembly. The valve box assemblies are arranged at the fluidend. The pull rod mounting sleeves are arranged at the power end. Each transmission assembly comprises a pull rod, a pull rod sealing assembly, a plunger, one plunger sealing assembly and an adjustment connecting assembly. Each plunger sealing assembly comprises two first metal push sleeves and a first sealing body which are mounted between each plunger and the corresponding plunger mounting sleeve. Fluid inlets of the valve box assemblies are connected with a fluid inlet pipe. Fluid outlets of the valve box assemblies are connected with a fluid outlet pipe. The plunger mud pump can realize interchange of single fluid, double fluids and multiple fluids, can carry out mixing of fluid at different proportions and is stable in fluid pumping pressure and uniform in fluid mixing.

Owner:SHANDONG ZHONGTAN MACHINERY

Inclined strut buckle and sliding sleeve thereof for steel pipe scaffold

InactiveCN103089000BNot easy to dropPrevent slidingScaffold connectionsEngineeringMechanical engineering

The invention discloses an inclined strut buckle and a sliding sleeve thereof for a steel pipe scaffold. The buckle comprises the sliding sleeve for sleeving on a fixed steel pipe in a sliding mode and a boss which is arranged on one side of the outer circumference face of the sliding sleeve in a protruded mode. A face of the boss is provided with an arc positioning supporting groove for positioning an inclined strut steel pipe. The axis of the positioning supporting groove is crossed with an axial space of the sliding sleeve with an included angle ranging from 30 degrees to 60 degrees. The sum of the radius of an inner hole of the sliding grove and the radius of the positioning supporting groove is smaller than the distance between axes of the positioning supporting groove and the sliding sleeve. A connection groove is arranged in the bottom face of the positioning supporting groove, wherein an extension direction of the connection groove is identical with an extension direction of the positioning supporting groove and the connection groove penetrates through the inner hole of the sliding sleeve. A press module for pressing the inclined strut steel pipe in the positioning supporting groove in an arranged mode is arranged on the face of the boss. As the sliding sleeve is sleeved on the fixed steel pipe, a buckle body just needs to be fixedly connected with the inclined strut buckle and installation and dismantling are convenient. Besides, the buckle body is not prone to fall off.

Owner:朱新伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com