Rolling device for compressing insole

A rolling device and insole technology, applied in the field of rolling devices, can solve problems such as degumming of multi-layer insoles, and achieve the effects of avoiding degumming, firm connection, and enhanced compression strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

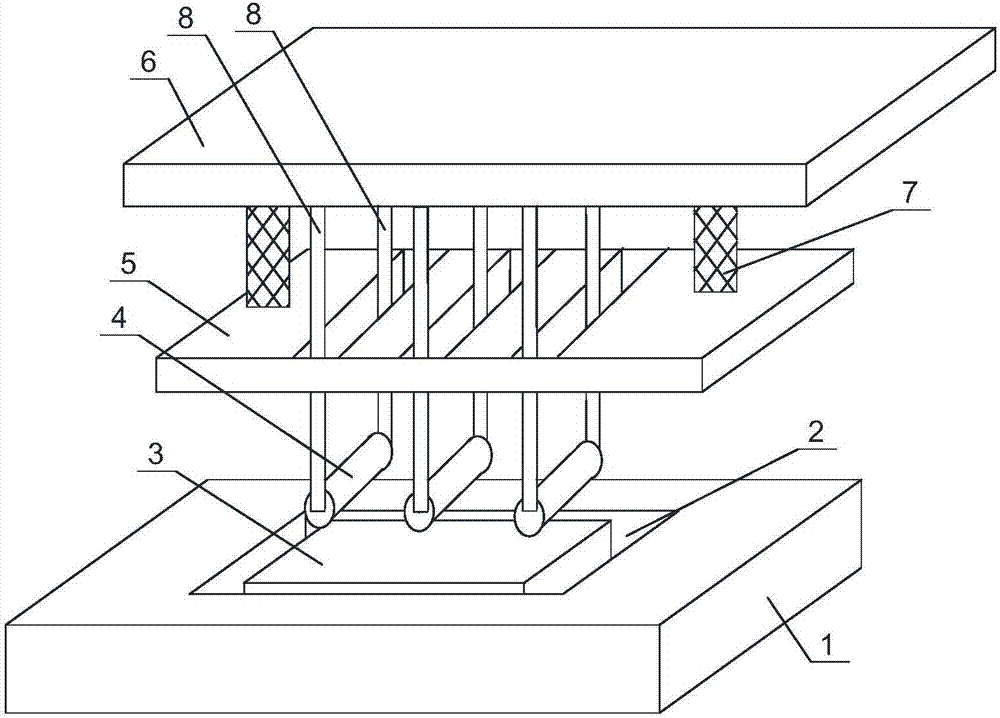

[0021] Such as figure 1 As shown, the present invention is used for the rolling device of compressing insole, comprises the workbench 1 that table top is rectangular, is provided with groove 2 on described workbench 1, and the storage board 3 that places insole is installed in groove 2, so The groove walls on both sides of the groove 2 are provided with slide rails for the object board 3 to slide along the long side direction of the workbench 1, and at least two rollers 4 are arranged above the groove 2, and all the rollers 4 are arranged along the working table. The direction of the long side of the table 1 is arranged in sequence, the central axis of the roller 4 is parallel to the broad side of the table top of the workbench 1, and a pressing plate 5 is arranged above the roller 4. 5 through holes, the through holes correspond to the rollers 4 one by one, a fixed plate 6 is connected above the pressing plate 5, and each roller 4 is connected and fixed to the fixed plate 6. ...

Embodiment 2

[0024] Based on Embodiment 1, a cooling fan is installed inside the workbench 1 , and the air outlet of the cooling fan communicates with the groove 2 . The air cooler is controlled by an electronic switch, and the electronic switch is connected with a pressure sensor, and the pressure sensor is installed on the pressing plate 5 . The air cooler acts as a condensation effect, so that the adhesive can be solidified quickly and the production speed of the insole is accelerated; when the roller is rolling the insole, the adhesive needs to maintain fluidity, but whenever the pressure plate is pressed on the insole, the glue needs to be made The adhesive solidifies quickly and plays the role of sticking and fixing, so that the layers of the insole are glued together more firmly; when the pressure plate is pressed down on the insole, the pressure sensor senses the change of pressure and sends a signal to the electronic switch, and the electronic switch Start the cooling fan, and whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com