A kind of rtm forming method of composite material blade

A molding method and composite material technology, which is applied in the field of liquid molding of resin-based composite materials, can solve the problems of scrapped parts, inability to fully fit in place, few structural interweaving points, structural stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

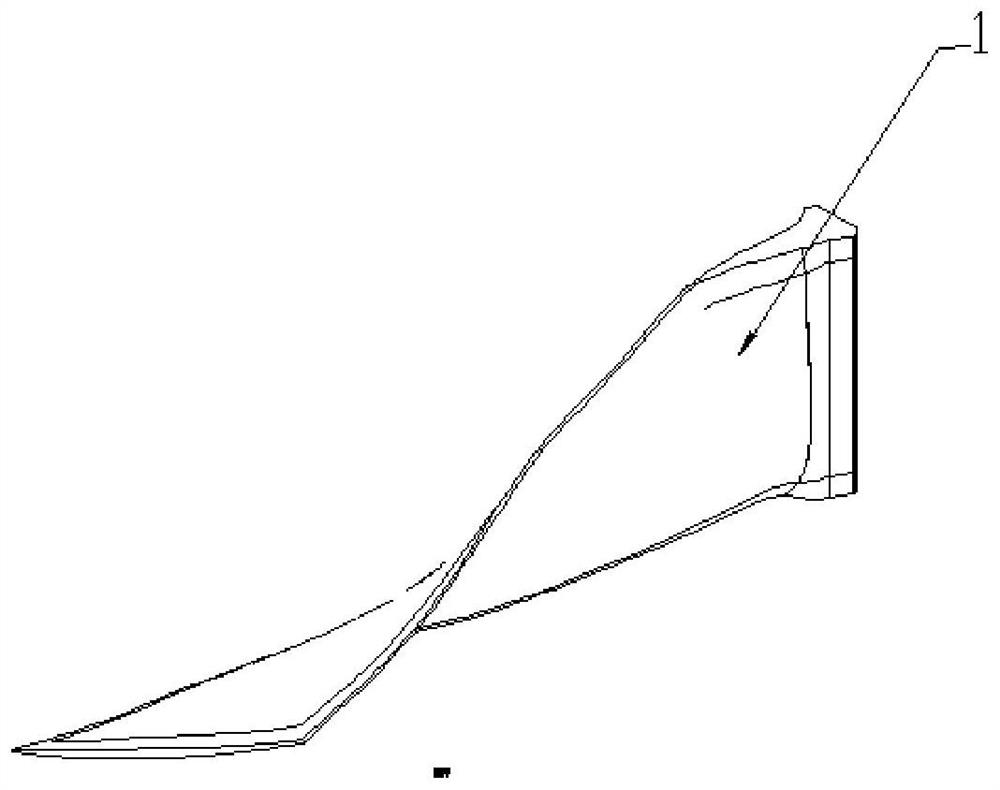

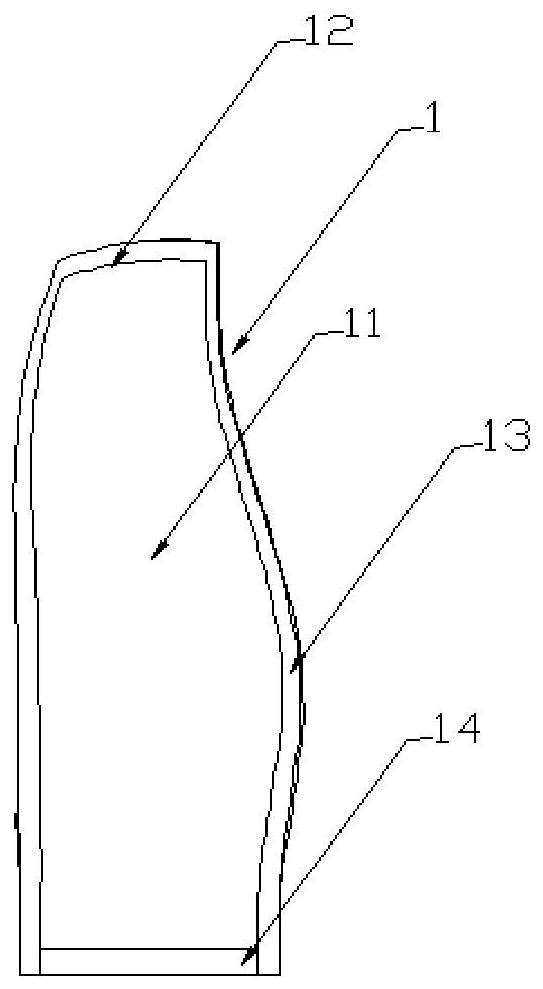

[0055] The blade prefabricated body 10 is a variable thickness 2.5D woven structure fan blade prefabricated body, the material is CCF800, and the fiber volume content of the material is 55%±3%; CCF800 is a T800 grade carbon fiber fabric with a specification of 12K produced by Shandong Weihai Development Company , the injection resin adopts PR520 high-toughness liquid molding resin from CYTEC Company. The external dimensions of the blade body 1 are: 750mm×300mm (length×width), and the external dimensions of the blade prefabricated body are 800mm×340mm (length×width). There is a margin of 20mm around the body. The specific molding steps are as follows:

[0056] 1) The blade 1 is composed of a blade body 11 and a blade margin area 12, the blade margin area 12 is composed of a blade tenon margin area 13 and a blade edge margin area 14, and the blade prefabricated body 10 is an intermediate body of the blade 1 before RTM molding;

[0057] 2) The molding die 4 is processed from a P2...

Embodiment 2

[0068] The blade prefabricated body 10 is a variable thickness 2.5D woven structure fan blade prefabricated body, the material is T700, and the fiber volume content of the material is 58% ± 3%; T700 is a T700 grade carbon fiber fabric with a specification of 12K produced by Toray Corporation of Japan The resin used for injection is ACTECH1304 high-toughness liquid molding resin of AVIC Composites Co., Ltd. The overall dimensions of the blade body 1 are: 720mm×260mm (length×width), and the overall dimensions of the blade preform are 780mm×320mm (length×width) ), leaving a margin of 30mm around the blade prefabricated body, the specific forming steps are as follows:

[0069] 1) The blade 1 is composed of a blade body 11 and a blade margin area 12, the blade margin area 12 is composed of a blade tenon margin area 13 and a blade edge margin area 14, and the blade prefabricated body 10 is an intermediate body of the blade 1 before RTM molding;

[0070] 2) The molding die 4 is proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com