Inclined strut buckle and sliding sleeve thereof for steel pipe scaffold

A scaffolding and sliding sleeve technology is applied in the connection of scaffolding, housing structure support, housing structure support and other directions, which can solve the problems of easy falling of fasteners, affecting the disassembly and assembly of scaffolding, and troublesome disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

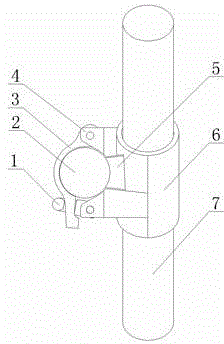

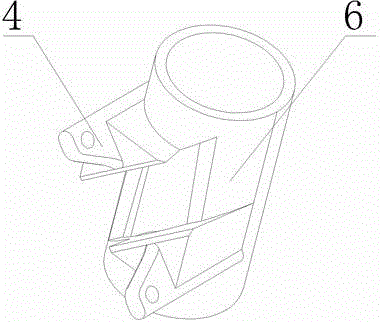

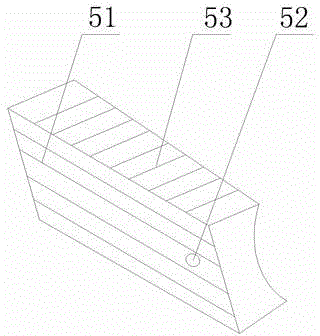

[0022] The embodiment of the steel pipe scaffold of the present invention is used the brace fastener: as Figure 1-4 As shown, including the sliding sleeve 6 and the boss on one side of the outer peripheral surface of the sliding sleeve 6, the inner diameter of the sliding sleeve 6 is adapted to the outer diameter of the fixed steel pipe 7, so that the sliding sleeve 6 can be slidingly arranged on the outer surface of the sliding sleeve 6. On the fixed steel pipe 7; on the table surface of the boss, an arc-shaped positioning support groove is provided, and the groove wall surface of the positioning support groove is partially adapted to the outer peripheral surface of the diagonally braced steel pipe 2, so that the diagonally braced steel pipe 2 can be supported, and the axis of the positioning support groove is in line with the The axes of the sliding sleeve 6 intersect in space with an included angle of 45°, and the sum of the radii of the positioning support groove and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com