Large-section water-blocking conductor for submarine cable

A technology for water-blocking conductors and submarine cables, applied in the directions of submarine cables, conductors, insulated cables, etc., can solve the problems of uneven deformation, affecting the degree of compaction, and low degree of compaction, so as to improve the water-blocking effect and improve the tightness. The effect of low pressure and low cost of transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

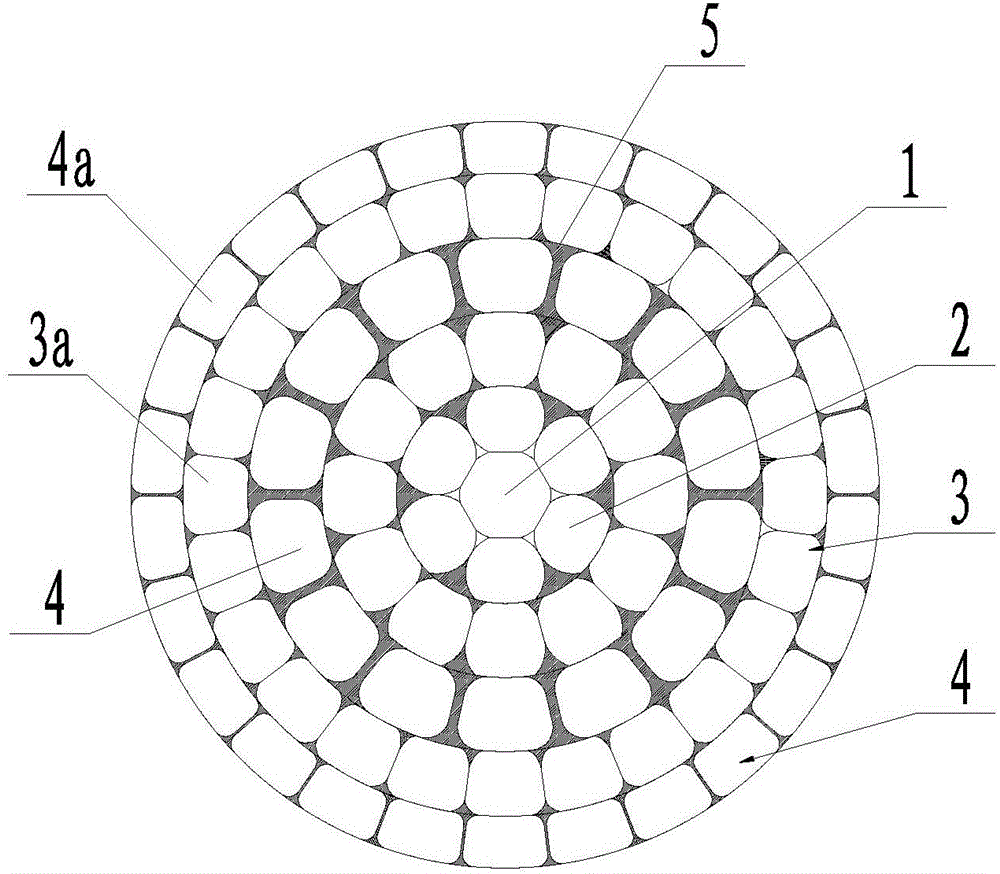

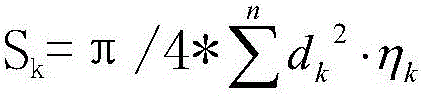

[0031] Such as figure 1 As shown, a large cross-section water-blocking conductor for submarine cables includes a support core 1. In this embodiment, the support core 1 is composed of a solid circle or a circle formed by a plurality of single wires tightly twisted. There are n layers of round wire twisted layers 2 arranged on the outer side of the support core 1, where n is a natural number greater than or equal to 1. In this embodiment, the value of n is 2; the outer side of the support core 1 is provided with two layers of round wire twisted layer 2; Tightly compressed strands 3 are arranged between the twisted layers 4 . The number of single round wires in each layer of the two-layer round wire stranding layer 2 is six and twelve from the inside to the outside; the number of single wires in each layer of the two-layer type wire twisting layer 4 is fourtee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com