An ironing device for suit processing

A technology for ironing equipment and suits, which is applied in the field of garment production and processing, can solve the problems of poor ironing treatment effect of suits, affecting the appearance of suits, and folds of suits, and achieves smooth ironing process, convenient ironing, and enhanced compression degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

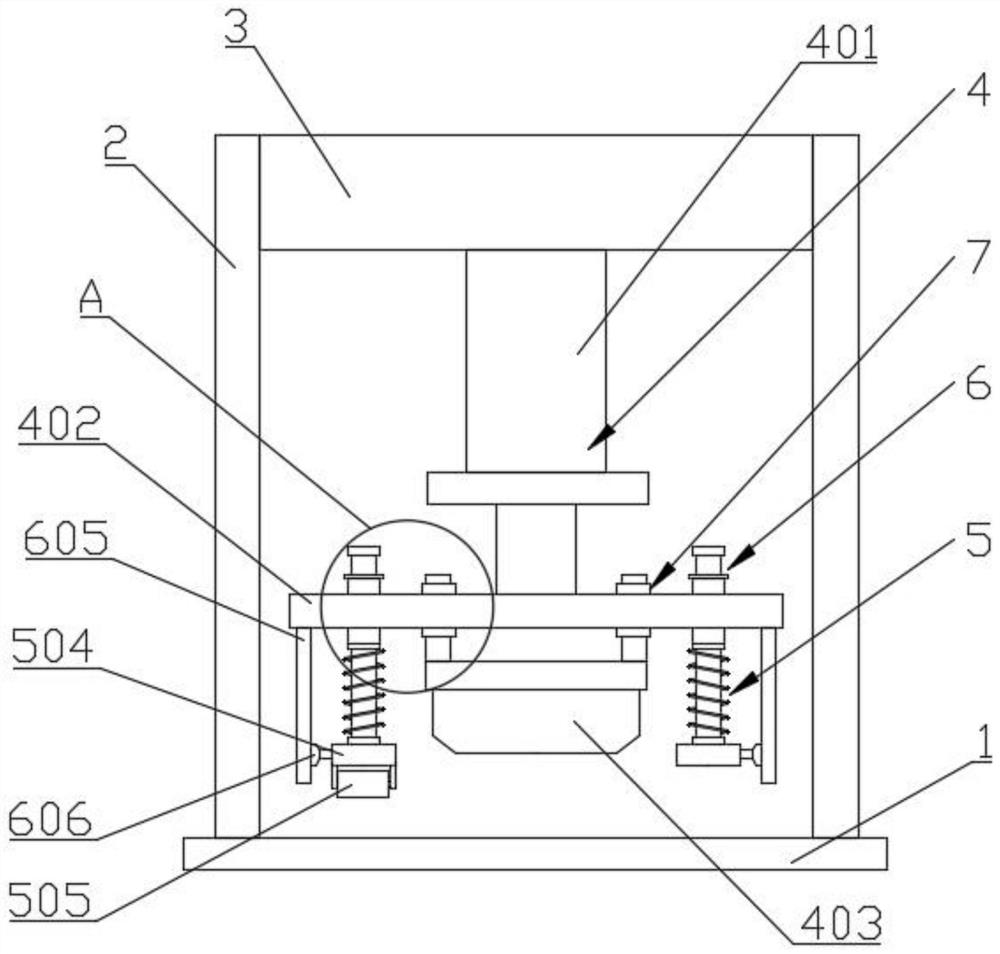

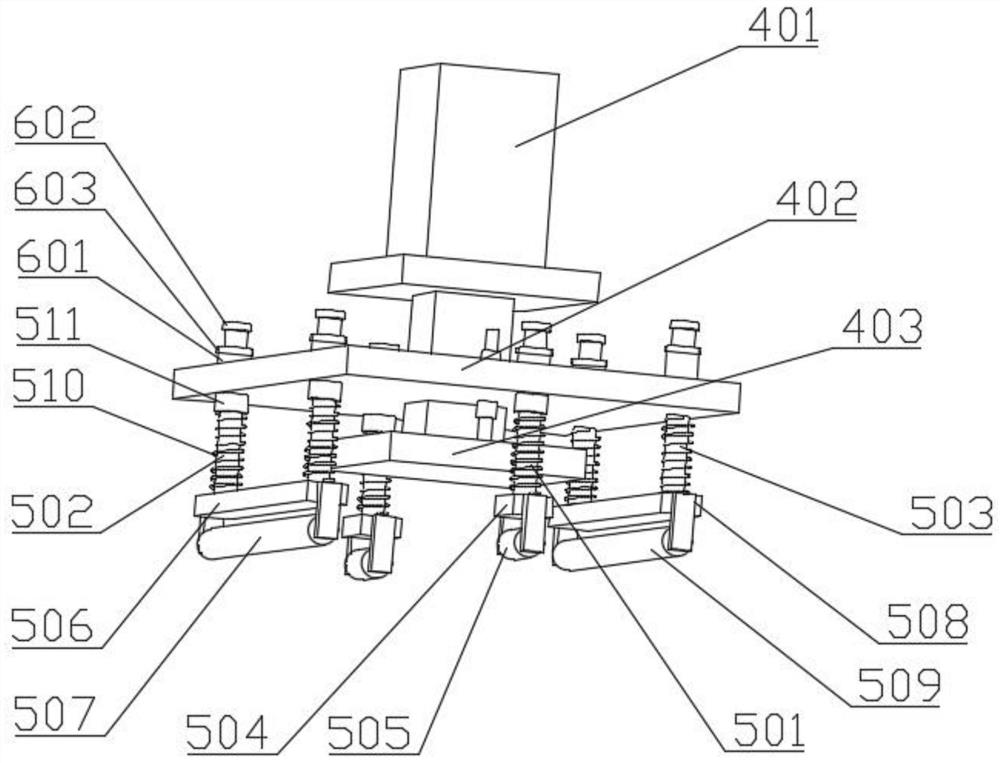

[0046] The mounting plate 402 is provided with a pressing assembly 5 for pressing and flattening the suit during the ironing of the suit;

[0049] Between the pressing component 5 and the mounting plate 402, a pressing adjusting component 6 for adjusting the degree of pressing the suit is provided.

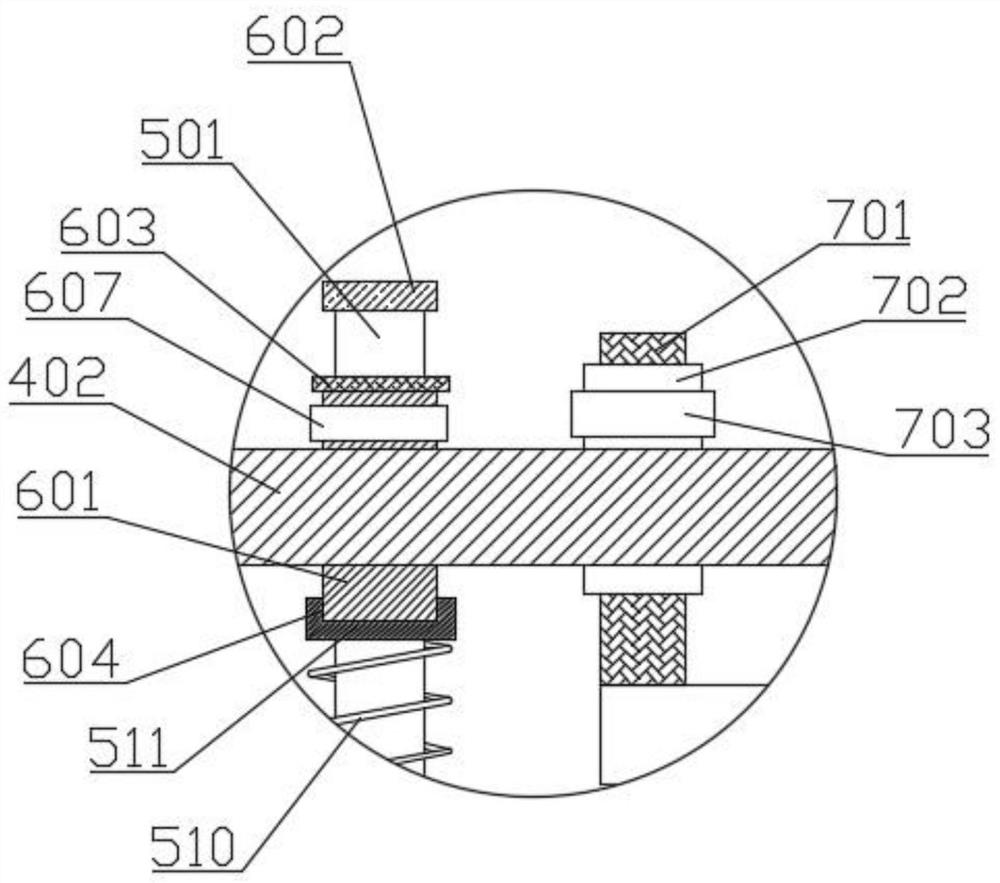

[0050] The compression adjustment assembly 6 includes a set between the side compression rod 501 and the mounting plate 402, and between the front compression rod 502 and the mounting plate 402.

[0051] The sliding sleeve 601 is threadedly connected to the mounting plate 402, and the sliding sleeve 601 and the mounting plate 402 are threadedly connected,

[0052] The upper end of the upper spring seat 511 is provided with an installation groove 604, and the bottom of the sliding sleeve 601 is located in the installation groove 604,

[0055] The mode adjustment assembly 7 includes a vertical connection between the ironing assembly 403 base and the mounting plate 402

[0070] In the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com