Sand box having stability

A stable, sand box technology, applied in the field of foundry tooling, can solve the problems of difficult alignment of the upper and lower sand boxes, scrapped castings, easy damage, etc., and achieve the effects of preventing the deformation of the sand box, protecting the quality, and increasing the degree of compaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

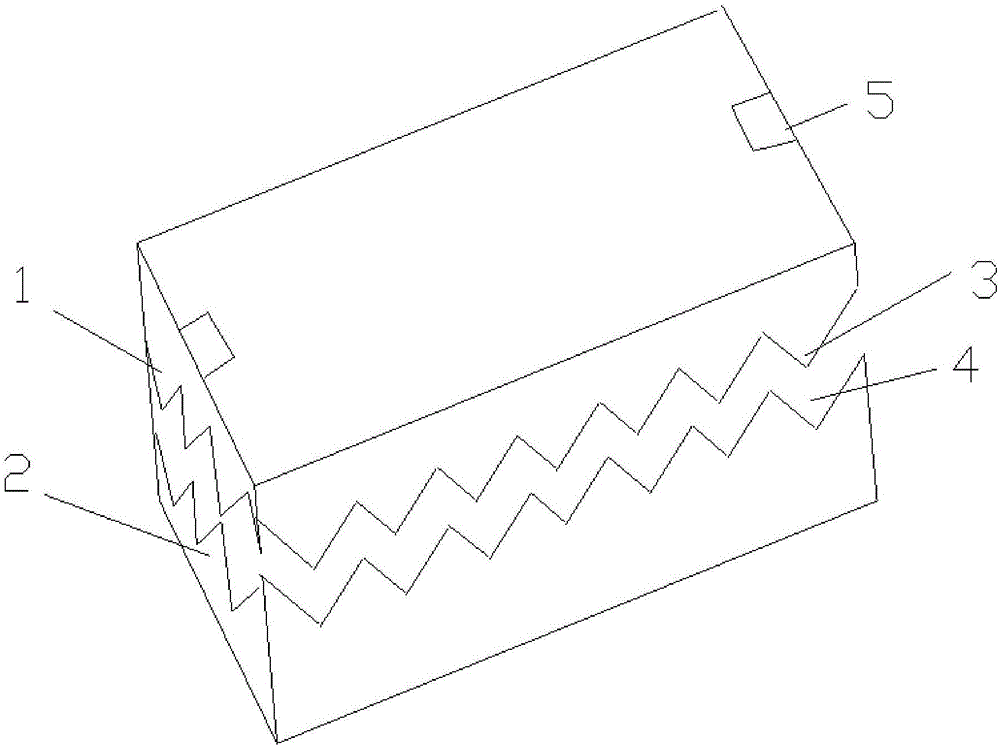

[0015] Such as figure 1 , a stable sand box provided by this embodiment includes an upper sand box 1, a lower sand box 2, a protrusion 3, a groove 4 and a handle 5; the lower end of the upper sand box 1 is provided with more than one protrusion 3 , the upper end of the lower flask 2 is provided with more than one groove 4 adapted to the protrusion 3 .

[0016] In this embodiment, the protrusions 3 and the grooves 4 are triangular prism structures, and the protrusions and the grooves are adapted to each other, and they fit tightly after being pressed together. The upper sand box 1 is provided with a handle 6 to facilitate lifting.

Embodiment 2

[0018] In this embodiment, the protrusions and grooves are cuboid structures.

Embodiment 3

[0020] In this embodiment, the protrusions and grooves are pyramid structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com