Pedal type film heat sealing machine with clamping mechanism

A clamping mechanism, film heat sealing technology, applied in envelope/bag manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems of high energy consumption, loud noise, large space occupation, etc., to achieve low energy consumption, saving The effect of electricity consumption and low work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

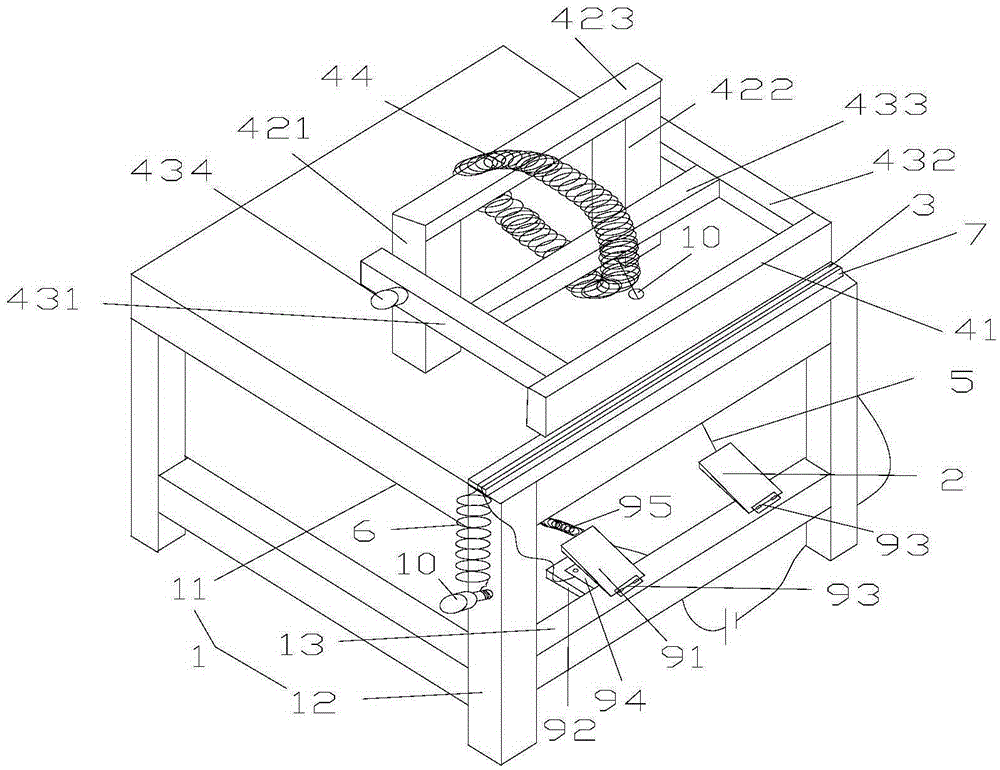

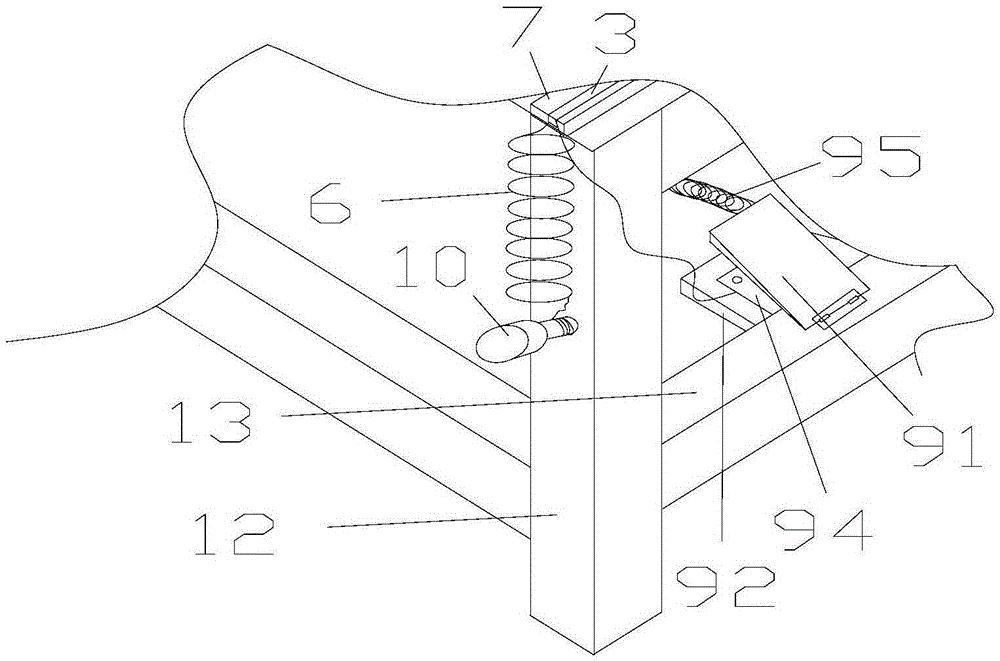

[0030] Such as Figure 1-2 As shown, this embodiment has a foot-operated film heat sealing machine with a clamping mechanism, including a workbench 1, a pressing heat sealing mechanism, a pedal 2, a resistance wire 3, a transmission mechanism, and a clamping mechanism.

[0031] The workbench 1 of this embodiment includes a workbench top 11 , table legs 12 and foot rods 13 arranged between adjacent table legs 12 . Pedal 2 is inclined shape, and its front end is lower and rear end is higher. Its front end is hinged with pedal rod 13 by hinge 93, and its rear end links to each other with the bottom of transmission mechanism, and transmission mechanism top links to each other with downward pressure heat sealing mechanism.

[0032] The downward pressure heat sealing mechanism includes a support frame assembly, a connecting frame assembly, and a lower pressing plate 41 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com