Convenient liquid mixing split plunger slurry pump

A split-type, mud pump technology, applied in the direction of liquid displacement machinery, components of pumping devices for elastic fluids, variable displacement pump components, etc., can solve the problem that the surface is easy to be corroded, worn, and the operation and maintenance costs are high , short device life and other problems, to achieve the effect of preventing easy corrosion, easy operation and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

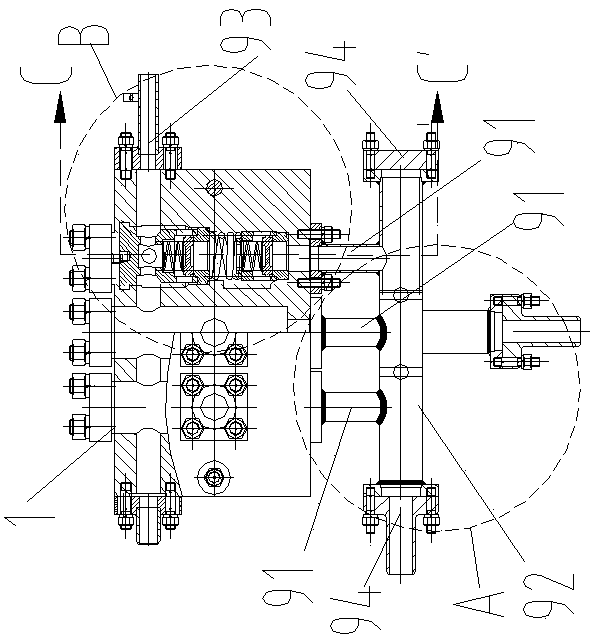

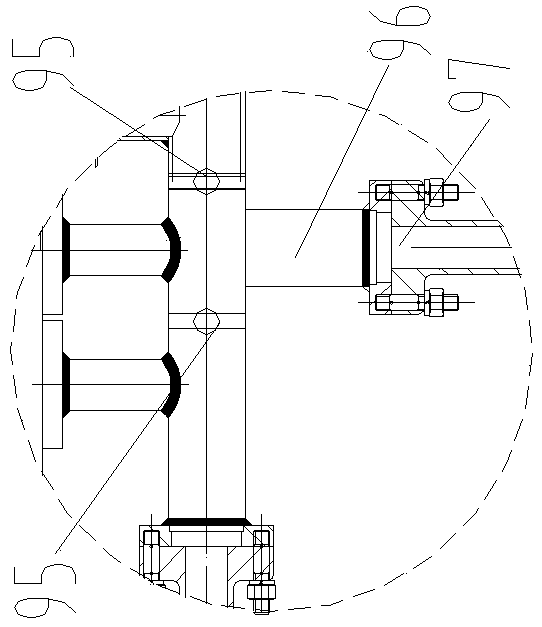

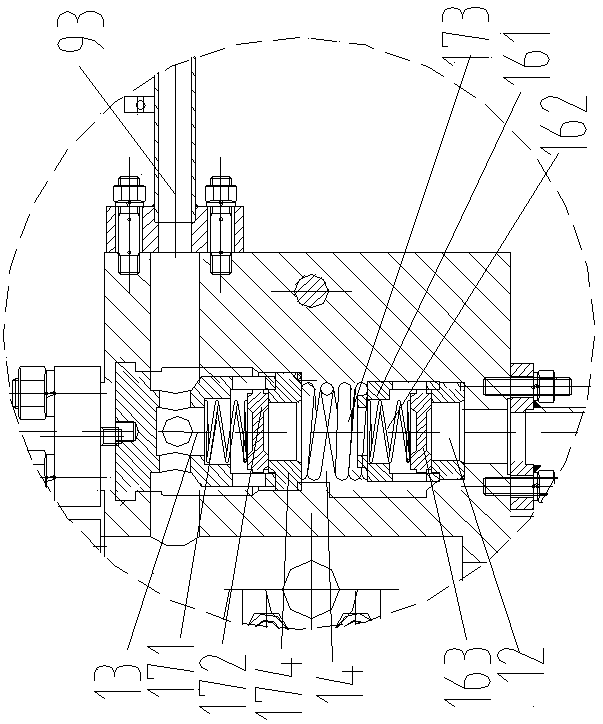

[0061] Example 1. Such as Figure 1-14 As shown, a split plunger mud pump that is convenient for liquid mixing includes a liquid end 1 and a power end 2 .

[0062] There are several pumping systems between the fluid end 1 and the power end 2;

[0063] Each pumping system includes a valve box assembly, a pull rod installation sleeve 21, and a transmission assembly; each valve box assembly is arranged on the fluid end 1, and each pull rod installation sleeve 21 is arranged on the power end 2; the transmission assembly includes a pull rod 4, a pull rod seal assembly , plunger 3, plunger sealing assembly, plunger horizontal position fine-tuning assembly 8, connecting rod 42.

[0064] The valve box assembly includes a valve box body 11, a liquid inlet 12 and a liquid outlet 13 arranged on the side wall of the valve box body 11, and a valve box inner cavity 14 arranged in the valve box body 11, which is arranged on The plunger installation sleeve 15 on the side wall of the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com