Light guide plate

A light guide plate, light source technology, applied in optics, light guides, optical components, etc., can solve the problems of high manufacturing cost, prominent hot spot phenomenon, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

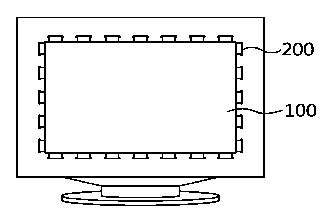

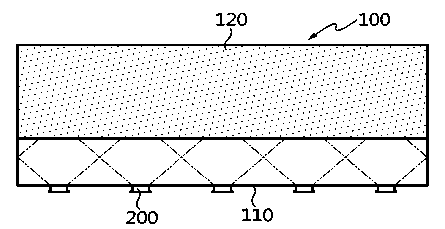

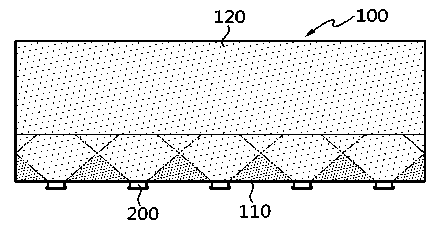

[0043] Such as figure 2 As shown: the light sources are placed on one side of the light guide plate 100 at a certain interval; a first concave hole structure 120 is provided in a region at a certain distance from the light incident surface 110 . The concave hole structure is composed of a plurality of concave holes located inside the light guide plate, that is to say, the concave holes are located on the surface (front surface or rear surface) of the light guide plate.

[0044] That is, a plurality of light sources 200 are placed at one side of the light guide plate 100 at certain intervals so that light enters from one side of the light guide plate 100 . The light source 200 uses LEDs, and the surface that allows light to enter the inside of the light guide plate 100 is called a light-incoming surface. In the light guide plate 100 , a first concave hole stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com