Coal cutter cutting resistance sensing method based on magnetorheological elastomer and sensor

A technology of magnetorheological elastomers, sensing methods, applied in the direction of volume/mass flow due to mechanical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Sensing method provided by the invention comprises the following steps:

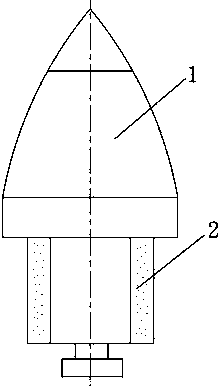

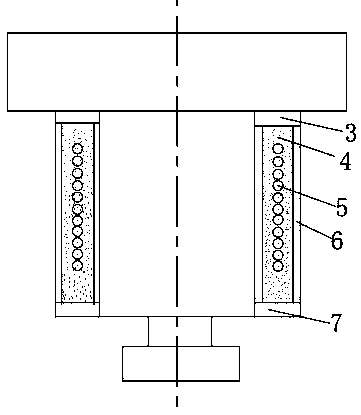

[0020] In the first step, the shearer pick is fixed on the shearer drum through a cutting resistance sensor based on magneto-rheological elastomer. The initial threshold of the cutting resistance is set to be smaller than the limit threshold of the cutting resistance determined according to the rated output power of the shearer. The cutting resistance received by the pick when cutting coal is transmitted to the magnetorheological elastomer through the pick, and the distribution of the internal magnetic particles of the deformed magnetorheological elastomer changes, so that the electrical parameters of the shearer's cutting resistance sensor changes, the electrical parameters are measured by the detection circuit to obtain the corresponding relationship between the change of the cutting resistance and the change of the electrical parameters, and the cutting resistance suffered by the cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com