Adjustable cable-peeling cutter

A wire stripping tool, adjustable technology, applied in the direction of dismantling/armored cable equipment, etc., can solve the problems of low efficiency, slow stripping speed, cable damage, etc., and achieve the goal of reducing labor intensity and labor cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

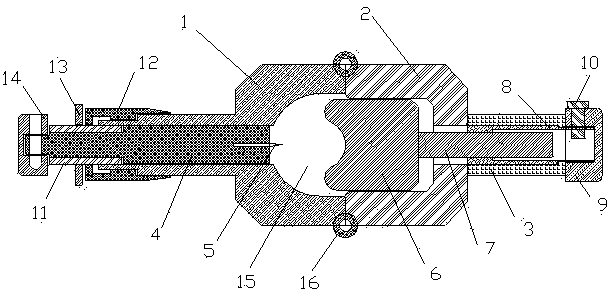

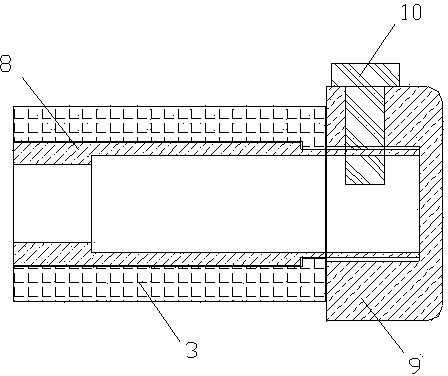

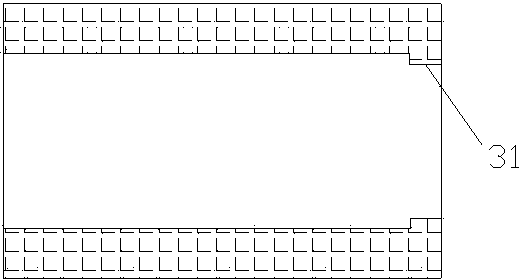

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as Figure 1-Figure 3 As shown, an adjustable wire stripping tool includes a tool holder 1 and a slider holder 2. After the tool holder 1 and the slider holder 2 are spliced together, a wire accommodating cavity 15 can be formed. Inside the handle of the knife holder 1 A first through hole communicating with the wire accommodating chamber 15 is provided, a knife seat 4 movable relative thereto is arranged in the through hole, and one end of the knife seat 4 close to the wire accommodating chamber 15 is fixed with a Cutter head 5.

[0021] Pass the wire through the wire accommodating chamber 15 , adjust the position of the knife holder 4 , pull the cable, and use the knife head 5 to realize stripping. The slider frame 2 is provided with a movable briquetting block 6 that can move relative thereto. According to the diameters of different wires, the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com