Method for machining paper shredding blades in punching forming mode

A stamping forming and processing method technology, applied in the field of paper shredding blade processing technology, can solve the problems of low material utilization rate, ineffective removal of intermediate waste, difficult breaking and separation, etc., so as to reduce production cost and improve material utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

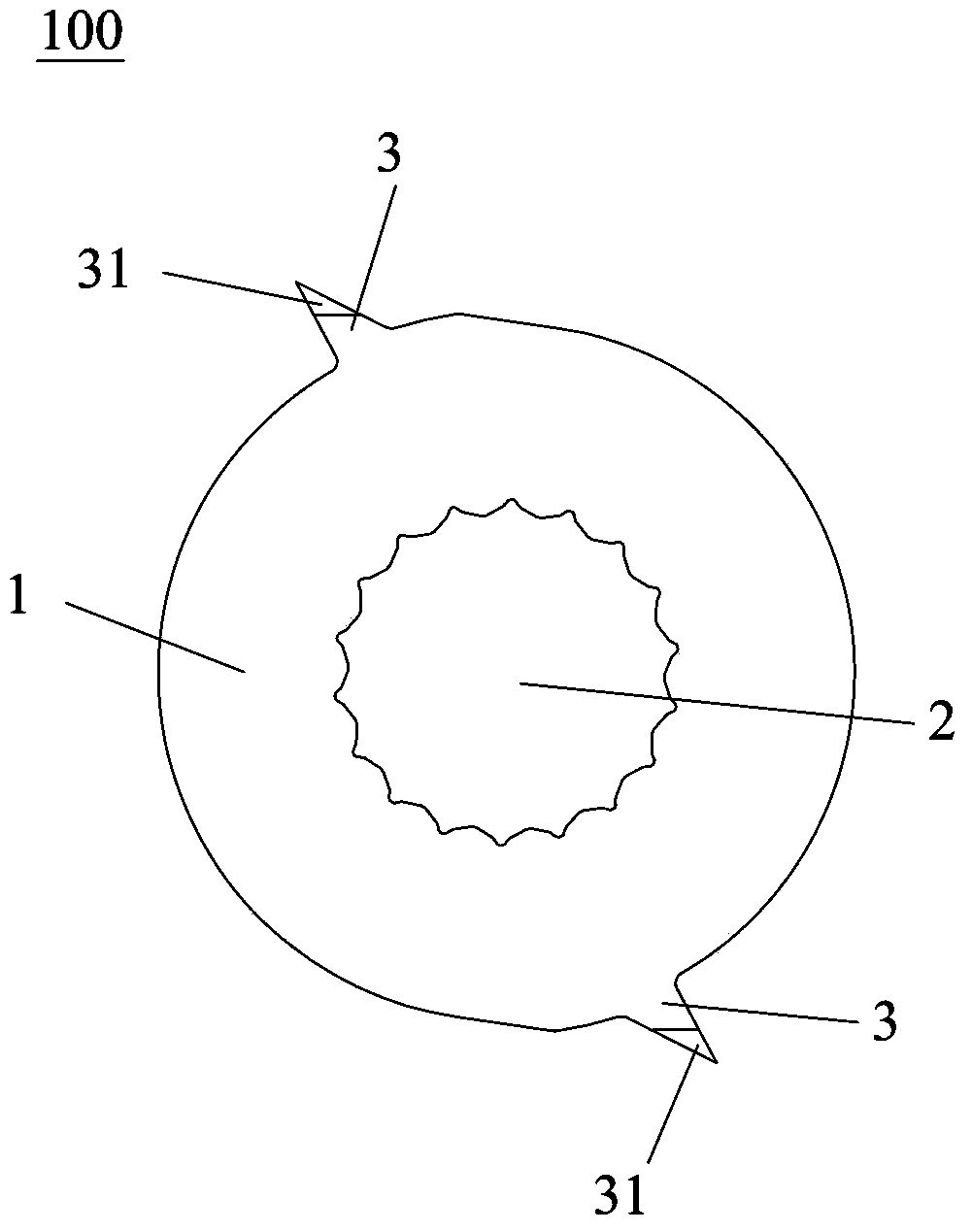

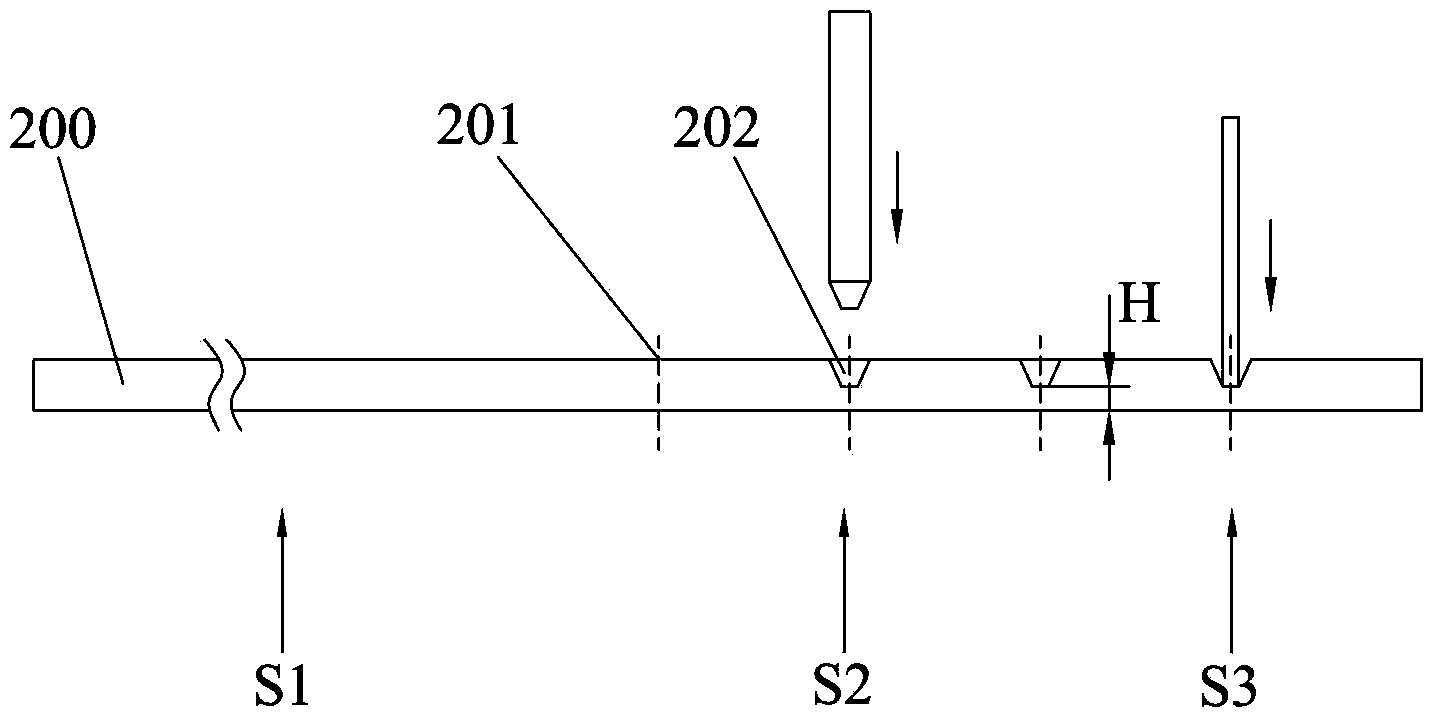

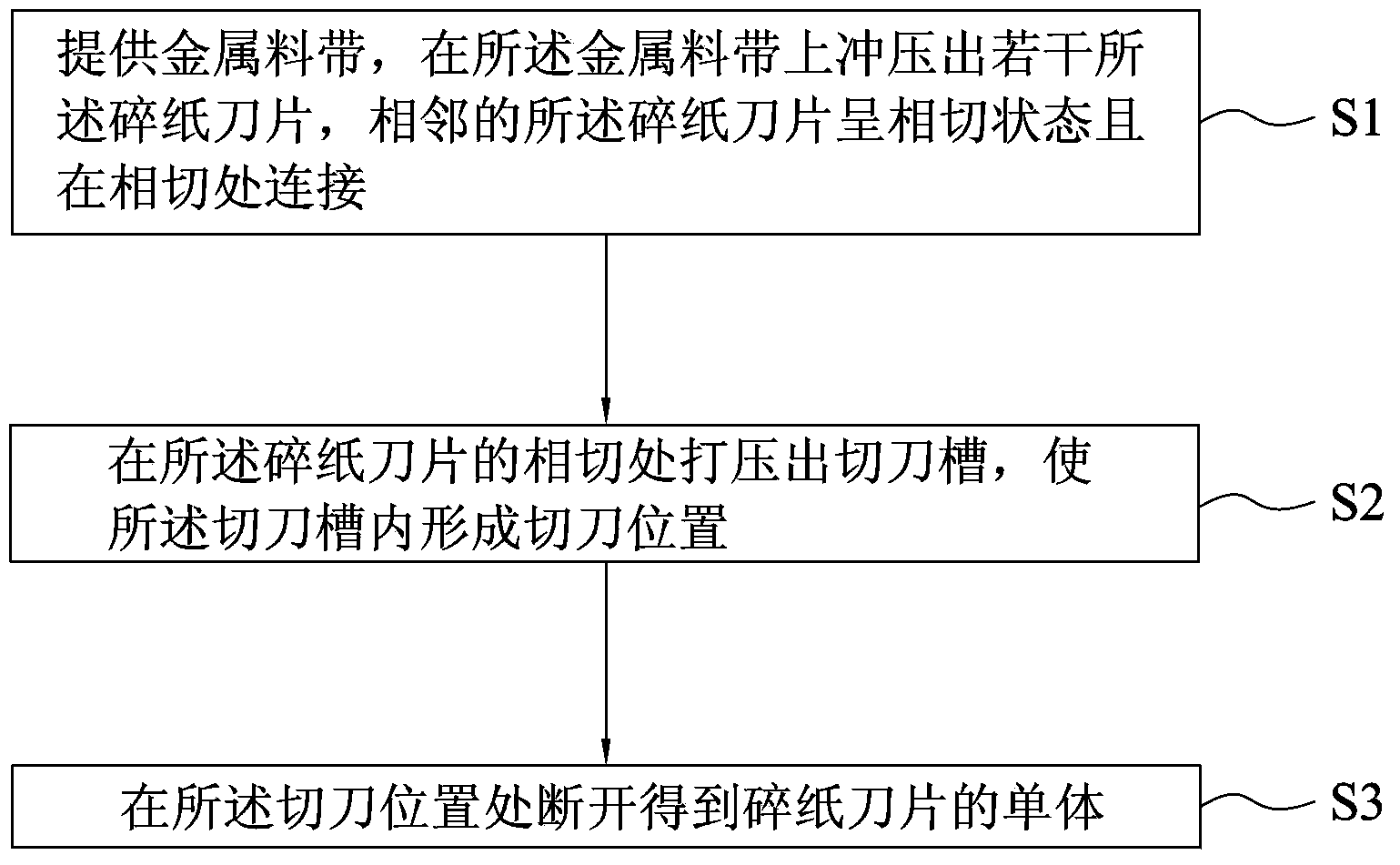

[0022] like figure 1 , figure 2 and image 3 as shown, figure 1 It is a paper shredding blade 100 processed by the processing method of the present invention. The paper shredding blade 100 includes a blade body 1, a mounting hole 2 at the center of the blade body, and a blade tip 3 at the periphery of the blade body. The stamping and forming processing method of the shredding blade 100 of the present invention includes the following steps: S1 provides a metal material strip 200, and stamps out a plurality of the shredding blades 100 on the metal strip 200, and the adjacent shredding blades 100 are in a phase. tangent state and connected at 201 tangent. S2 Press out the cutter groove 202 at the tangent position of the shredder blade 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com