A damping plate installation process on a ship

An installation process and damping technology, applied in the direction of hull panels, hulls, hull components, etc., can solve the problems of low firmness, easy to fall off, and cannot be widely used, saving man-hours, enhancing firmness, and reducing installation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and specific embodiments.

[0027] A damping plate installation process on a ship, comprising the following steps:

[0028] Degrease, polish and derust the metal surface of the substrate 1 to be laid;

[0029] Cut the damping plate 2 to the design specifications;

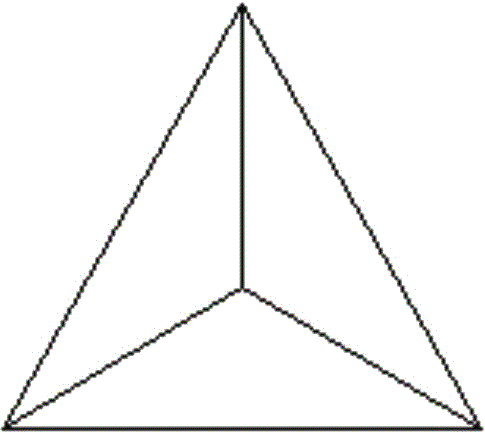

[0030] Mix and stir the damping glue and the fixing nail 3, and the fixing nail 3 is a regular tetrahedron;

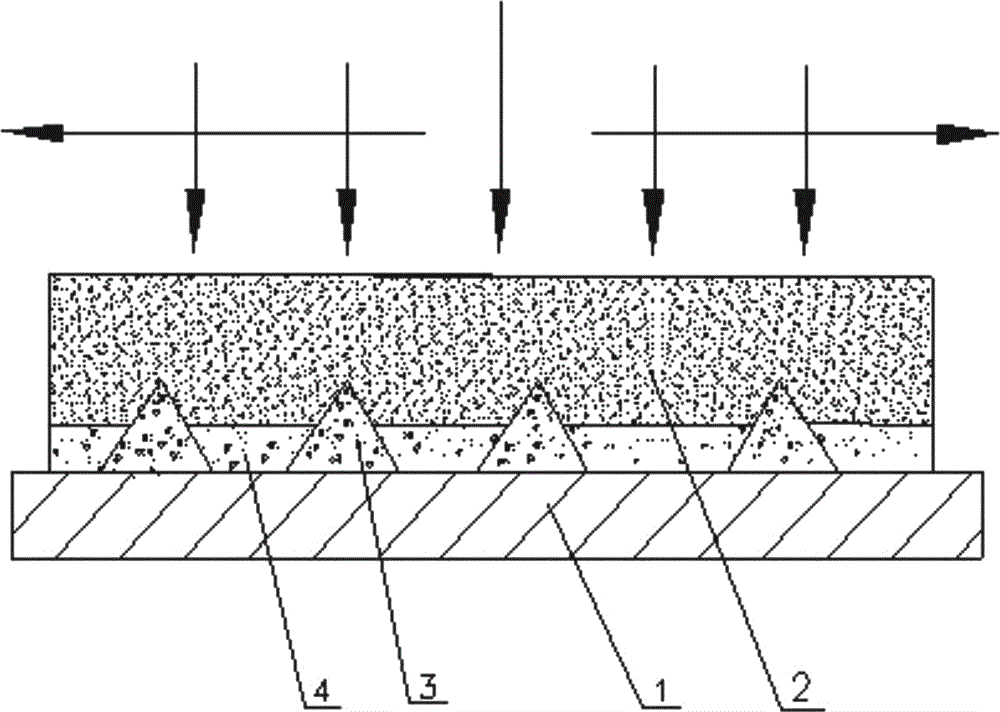

[0031] Apply the damping glue mixed with the fixing nails 3 evenly on the metal surface of the coated substrate 1 and the pasting surface of the damping plate 2, to form the adhesive film 4;

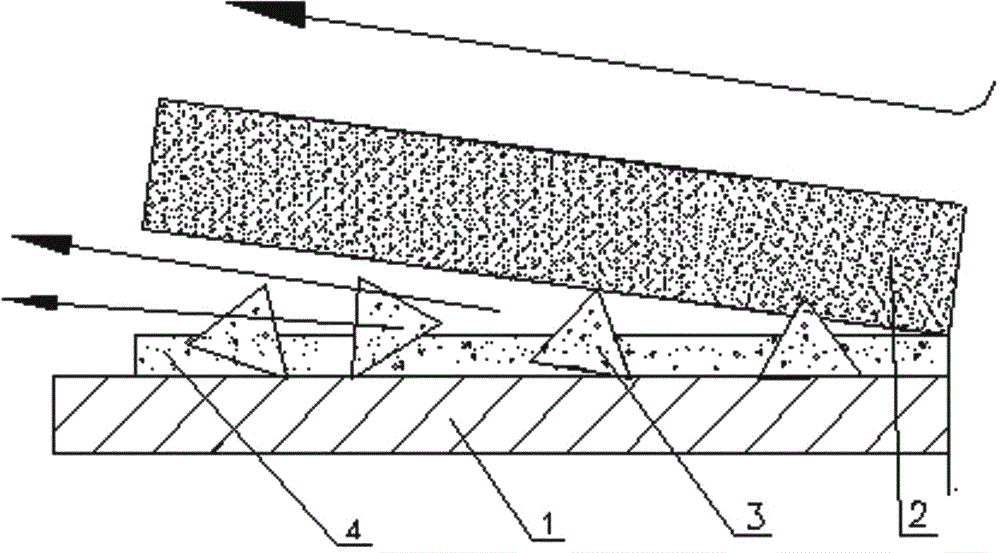

[0032] Position and paste the damping plate 2 relative to the metal surface of the coated substrate 1, such as figure 1 shown;

[0033] Tap the surface of the damping plate 2 after pasting, so that the lower plane of the fixing nail 3 is pasted on the metal surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com