Hoisting coupling device with cooperation of multiple cranes and detection method

A connecting device and crane technology, applied in the direction of cranes, transportation and packaging, load hanging components, etc., can solve the problems of crane wire rope stress mutation, relying on workers' operating experience, chaining major accidents, etc., to increase tensile and compressive performance, Enhanced anti-interference ability and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, one embodiment of the present invention is further described:

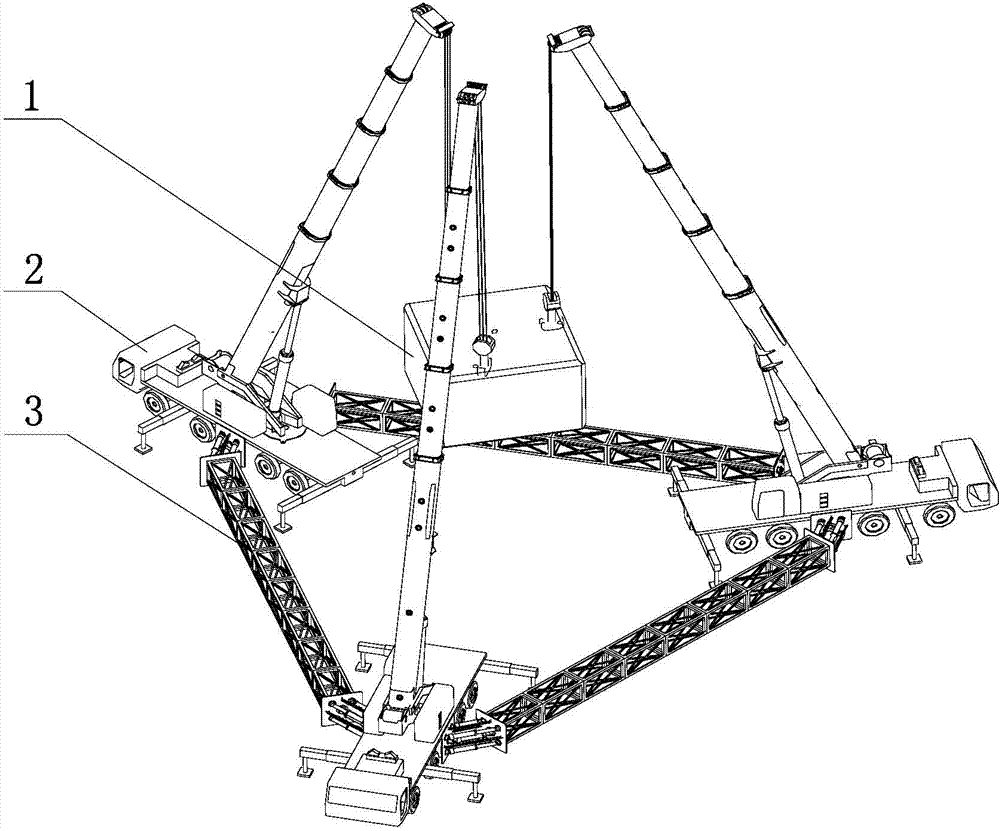

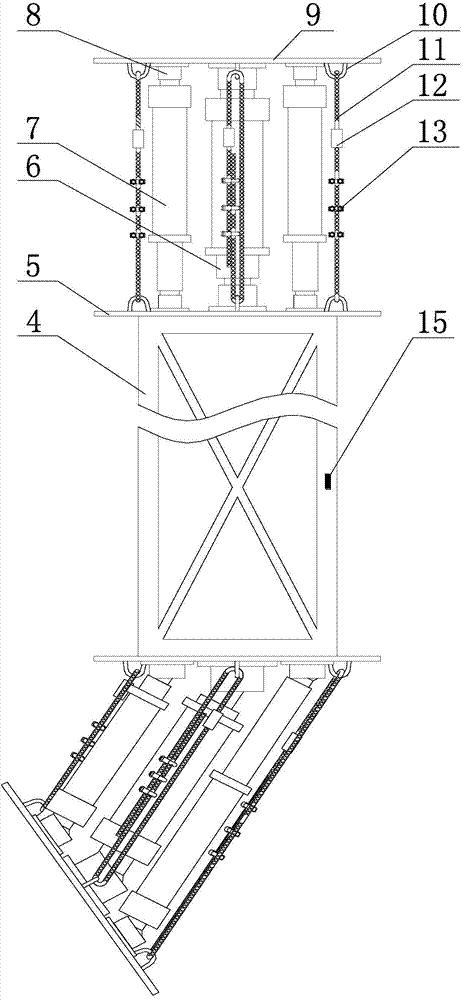

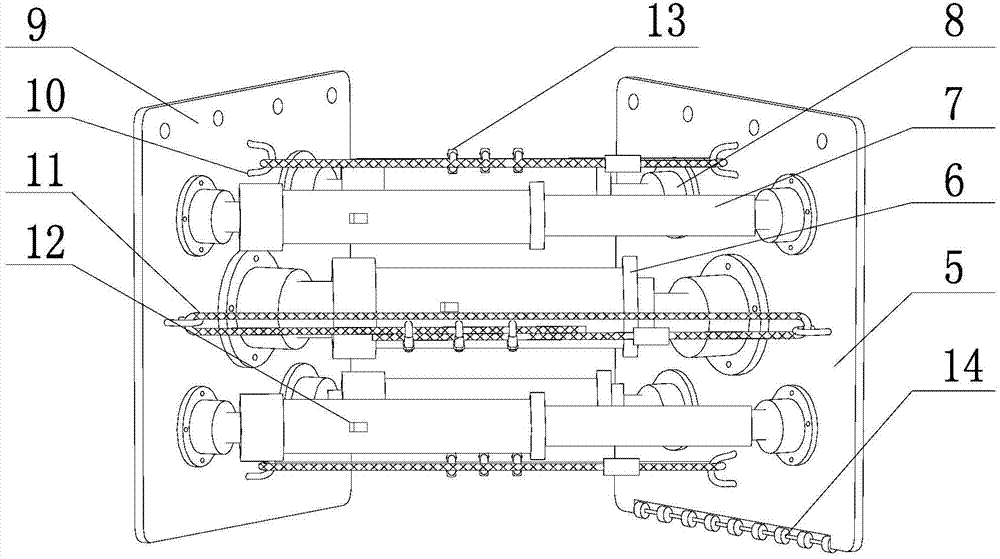

[0019] The detection method of the multi-crane cooperative hoisting connecting device of the present invention includes an upper computer, a lower computer and three groups of connecting brackets 3 with the same structure, each group of connecting brackets includes a truss 4, a truss support plate 5 installed at both ends of the truss, each truss A main hydraulic cylinder 6 is installed in the center of the support plate, and four identical auxiliary hydraulic cylinders 7 are evenly distributed around the main hydraulic cylinder. , the flange 8 is connected with the truss support plate 5 through bolts, the bar tails of the main hydraulic cylinder 6 and the auxiliary hydraulic cylinder 7 are connected with the flange 8 through a ball hinge, and the flange 8 is fixed on the frame fixing plate 9 through bolts . The frame fixing plate 9 is connected to the chassi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com